Preparation method of micro-foaming denitration catalyst carrier

A denitration catalyst and micro-foaming technology, which can be used in catalyst carriers, chemical instruments and methods, physical/chemical process catalysts, etc. The effect of clogging, easy control of preparation process, and increased active sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

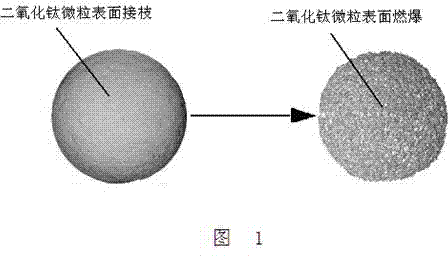

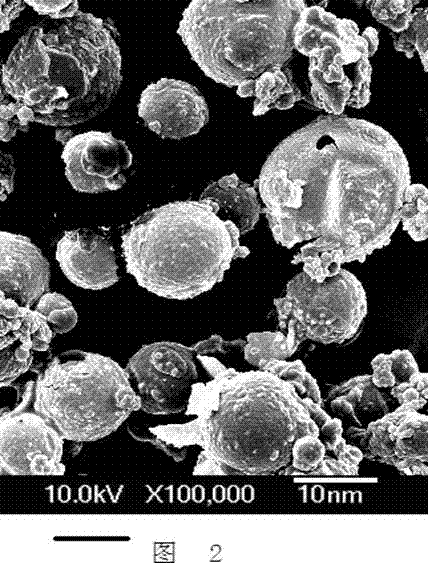

[0030] 1) 98 parts by weight of anatase-type titanium dioxide, 1.5 parts by weight of ammonium acrylonitrile, and 1.0 parts by weight of styrene-maleic anhydride amic acid resin were finely dispersed by a microcomputer for 30 minutes at 80-120°C, and the anatase-type Titanium dioxide is micronized and surface grafted and dispersed;

[0031] 2) Add 0.5 parts by weight of deflagration agent and 0.3 parts by weight of sodium hydrosulfate into step 1), and disperse finely by microcomputer ultrasonically for 10 minutes, and the detonation agent is evenly distributed on the surface of titanium dioxide particles through unsaturated acid ammonium salt;

[0032] 3) Put the material obtained in step 2) into the reaction kettle, set the temperature of the reaction kettle to 100°C, and the stirring speed to 300r / min. During the stirring process, add 0.3 parts by weight of potassium persulfate and react for 5 minutes. The deflagration agent is detonated under the action of the initiator, s...

Embodiment 2

[0037] 1) Pass 95 parts by weight of anatase titanium dioxide, 1.5 parts by weight of ammonium propylene-1,2,3-tricarboxylate, and 0.5 parts by weight of esterified styrene maleic anhydride resin at 80-120 °C Ultrasonic micro-dispersion by micro-machine for 15 minutes, micronization of anatase titanium dioxide and surface graft dispersion;

[0038] 2) Add 2 parts by weight of deflagration agent and 0.2 parts by weight of sodium bisulfite to step 1), and disperse finely for 5 minutes through a microcomputer ultrasonically, and the detonation agent is evenly distributed on the surface of titanium dioxide particles through unsaturated acid ammonium salt;

[0039] 3) Put the material obtained in step 2) into the reactor, set the temperature of the reactor at 100-200°C, and the stirring speed at 400r / min. During the stirring process, react 0.5 parts by weight of sodium hypochlorite for 10 minutes, and the combustion on the surface of titanium dioxide particles The detonation agent ...

Embodiment 3

[0045] 1) 96 parts by weight of anatase titanium dioxide, 1 part by weight of ammonium itaconate, and 1 part by weight of imidized styrene maleic anhydride resin were finely dispersed by a micromachine for 20 minutes at 80-120 ° C , Anatase titanium dioxide is micronized and grafted and dispersed on the surface;

[0046] 2) Add 1.5 parts by weight of deflagration agent and 0.2 parts by weight of sodium thiosulfate to step 1), and disperse finely for 10 minutes through a microcomputer ultrasonically, and the detonation agent is evenly distributed on the surface of titanium dioxide particles through unsaturated acid ammonium salt;

[0047] 3) Put the material obtained in step 2) into the reactor, set the temperature of the reactor at 100-200°C, and the stirring speed at 350r / min. During the stirring process, add 0.5 parts by weight of ammonium persulfate, and react for 5 minutes, and the titanium dioxide particles The detonation agent on the surface is detonated under the action...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com