Buoyancy material with composite sandwich damping structure and preparation technology of material

A buoyant material, composite structure technology, used in adhesive additives, synthetic resin layered products, non-polymer adhesive additives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

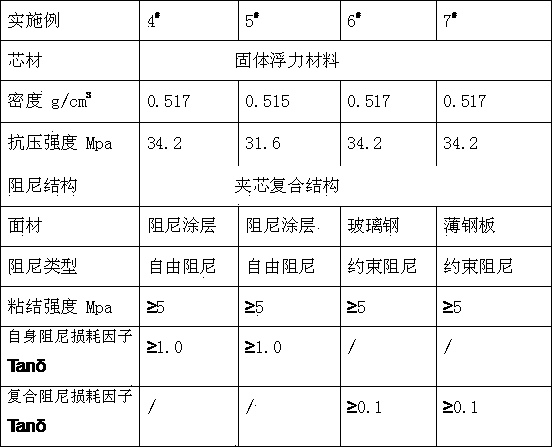

Examples

Embodiment 1

[0023] Weigh 1200 grams of epoxy resin, 280 grams of epoxy reactive diluent, and 55 grams of silane coupling agent, put them into a pre-mixing tank equipped with a stirrer, stir the liquid materials evenly, and put them into 1100 grams of graded hollow The glass beads are pre-mixed, and the pre-mixed material is put into a 10-liter kneader, and kneaded for 15 minutes. Add 360 grams of 3,3 , -Diethyl 4,4 , -Diaminodiphenylmethane, 150 grams of isophorone diamine curing agent, continue kneading for 60 minutes until the materials are mixed evenly. The discharged material is filled into a mold with an inner cavity size of 200×200×100mm, hot-pressed and solidified, and after demoulding, it is cured at 130°C for 4 hours to obtain a solid buoyancy material blank, which is machined into a buoyancy material module. Material density 0.517g / cm 3 , the uniaxial compressive strength is 34.2Mpa, the volume fraction of hollow glass microspheres is 64.0%

Embodiment 2

[0025] Take by weighing 180 grams of epoxy resin, 45 grams of epoxy reactive diluent, 11 grams of silane coupling agent, put into the premix tank equipped with agitator, stir the material evenly at room temperature, drop into 180 grams of graded The hollow glass microspheres are pre-mixed, and the pre-mixed material is put into a kneader and kneaded for 15 minutes. Add 136 grams of methyltetrahydrophthalic anhydride and 9 grams of 2-ethyl-4-methylimidazole catalyst, and continue kneading for 60 minutes until the materials are uniformly mixed. The discharged material is filled into a mold with an inner cavity size of 120×120×50mm, hot-pressed and solidified, and after demoulding, it is cured at 140°C for 4 hours to obtain a solid buoyancy material blank, which is machined into a buoyancy material module. Material density 0.515g / cm 3 , the uniaxial compressive strength is 31.6Mpa, and the volume fraction of hollow glass microspheres is 64.4%.

Embodiment 3

[0027] Preparation of damping coating: The damping layer is a polyether polyurethane elastomer, which is composed of two components A and B, component A is isocyanate prepolymer; component B is hydroxyl polyether, amine chain extender, silane Coupling agent, damping filler, etc.

[0028]

[0029] Preparation of component A:

[0030] Weigh 400 grams of D-2000 polyether polyol into a 1000ml three-necked bottle, heat to 100--110°C for vacuum dehydration for 1 hour. Cool down to below 60--70°C, put in 300g of MDI-50 polyisocyanate, heat to 80°C for prepolymerization for 2 hours, and place the material in a sealed container. Sampling and testing for free isocyanate content of 10%.

[0031] Preparation of component B:

[0032] Weigh the following components, and grind and disperse them evenly in a stirring grinding disperser to prepare component B.

[0033] Component B is based on 100 parts by mass of polyether polyol: D-2000 polyether polyol 100, amine chain extender 30, si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com