Low-temperature rapidly-vulcanized solid silicon rubber raw material and production method thereof

A rapid vulcanization and raw material technology, applied in the direction of metal processing, etc., can solve the problems that cannot meet the application requirements of high-precision and complex products, cannot bear the high temperature of solid silica gel, and material damage, etc., to solve the pressure damage of plastic structures, reduce mold matching and repair Difficulty of mold and the effect of increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

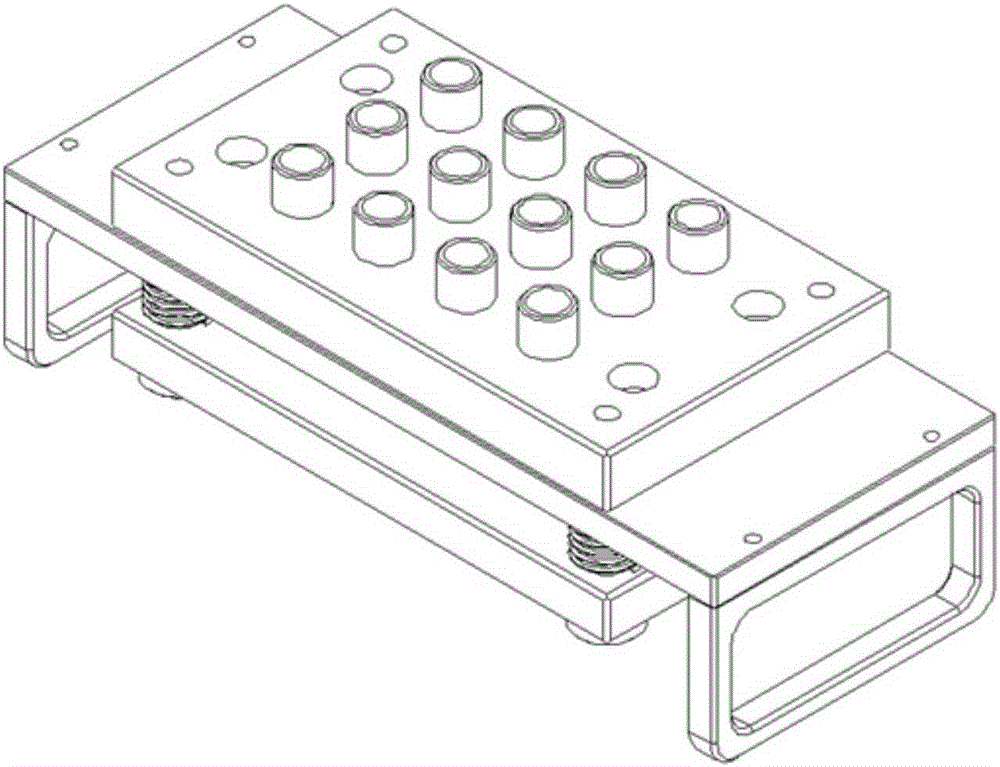

Image

Examples

Embodiment Construction

[0040] Embodiments of the present invention will be described in detail below. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

[0041] In one embodiment, a low-temperature rapid vulcanization solid silica gel raw material includes silica gel raw material, platinum vulcanizing agent and color masterbatch that are uniformly mixed together.

[0042]The main components of platinum vulcanizing agent are A component and B component. A component is a mixture containing vinyl rubber, fumed white carbon black and platinum complex; B component is a mixture containing vinyl rubber, fumed white carbon A mixture of black, terminal hydrogen silicone oil and inhibitors. The ratio between component A and component B is 1:1-3:1, preferably 2:1. More preferably, the proportion of component A to the total raw materials is 0.12%, and the proportion of component B to the total raw materials is 0.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com