Titanium or titanium-alloy material with micron-nano coarse-structure surface and preparation method thereof

A rough structure, titanium alloy technology, applied in the direction of surface reaction electrolytic coating, electrolytic coating, coating, etc., can solve problems such as easy to cause local inflammation, large difference in physical properties between coating and matrix, and implant loosening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

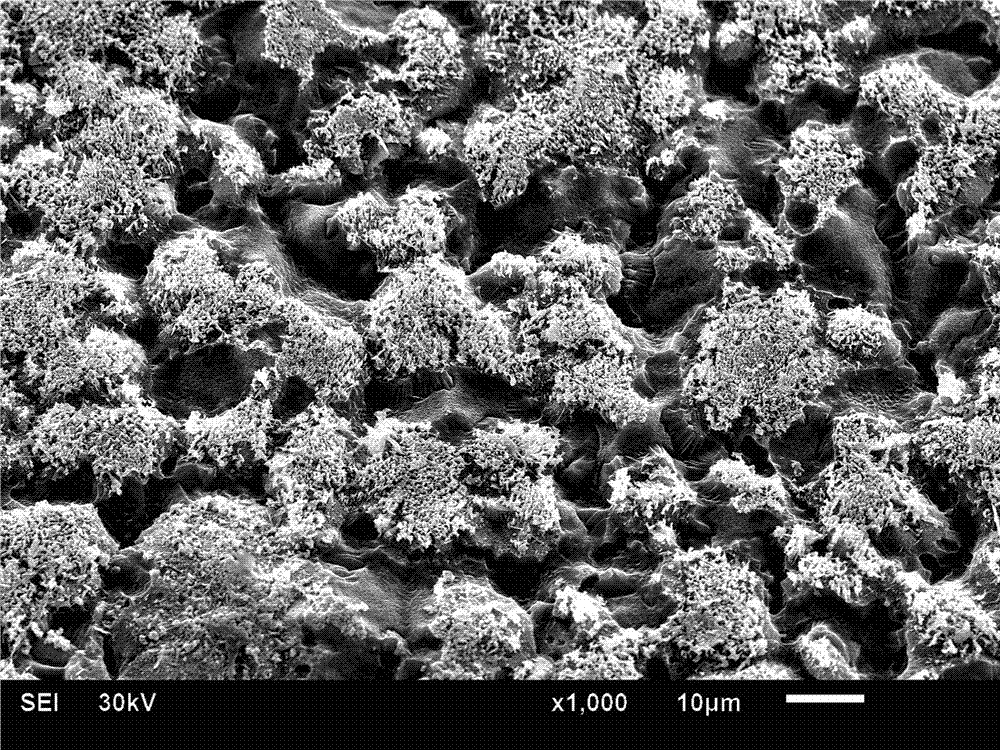

[0026] After polishing the surface of pure titanium material with sandpaper of different specifications from 400# to 1200#, chemical polishing method is used to clean the surface with 12wt% HF and 33%HNO 3 After soaking in the aqueous solution for 30 seconds, ultrasonically clean with acetone, ethanol and water for 30 minutes in sequence (ultrasonic power can be adjusted within 100-400W, preferably 250W), and vacuum freeze-dry for 24 hours.

[0027] Then, using a two-electrode system with titanium sheet as the anode and graphite as the cathode, electrochemical anodic oxidation was carried out at 20°C and a voltage of 100V / 2000Hz in an aqueous electrolyte solution containing 0.05wt% HF and 85wt% acetic acid. The distance is 4cm and the time is 1h. The titanium sheet after electrochemical anodic oxidation treatment was ultrasonically cleaned in deionized water for 5 minutes (ultrasonic power can be adjusted within 100-400W, preferably 250W), the electrolyte was cleaned, and stored...

Embodiment 2

[0030] After the surface of the pure titanium sheet is polished (or mechanically polished) with sandpaper in the manner of Example 1, chemically polished with a 3 After soaking in the aqueous solution for 30 seconds, the method of Example 1 was followed by ultrasonic cleaning with acetone, ethanol and water for 30min, and vacuum freeze-drying for 24h.

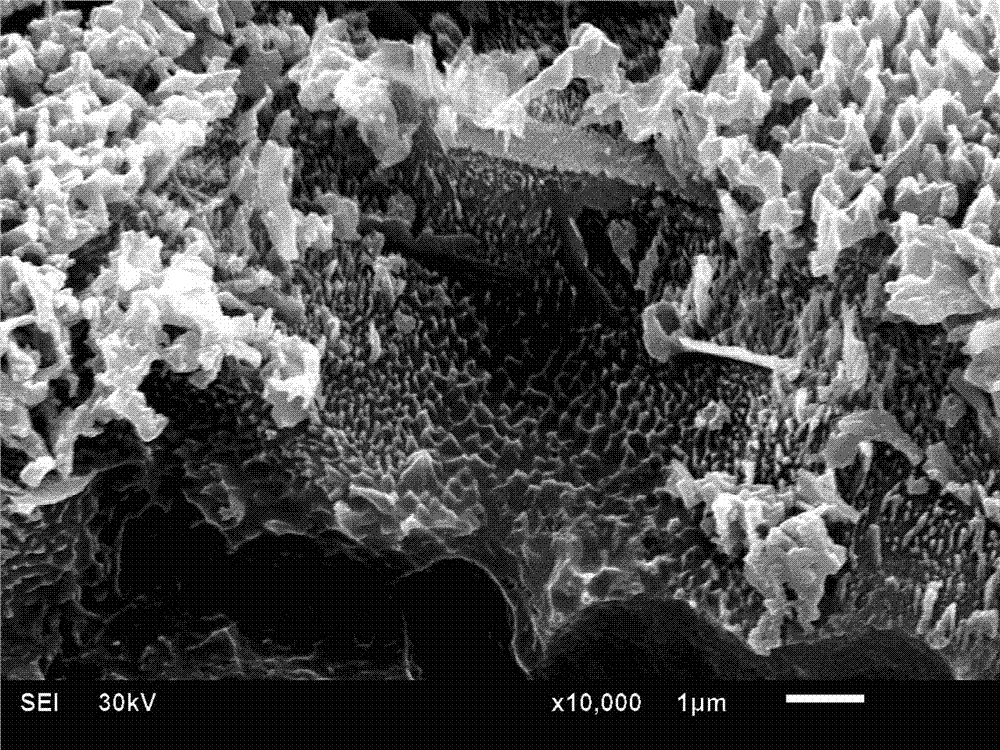

[0031] Then, using a two-electrode system with titanium sheet as the anode and platinum as the cathode, and using an aqueous solution containing 0.05wt% HF and 85wt% acetic acid as the electrolyte, electrochemical anodic oxidation was carried out at 80°C and a voltage of 100V / 2000Hz. The spacing is 5cm, and the time is 2h. The anodized titanium sheet was ultrasonically cleaned in deionized water for 5 minutes according to the method of Example 1, the electrolyte was cleaned, and stored in absolute ethanol for 48 hours. Also formed on the surface of the titanium sheet as Figure 4 The form is a multiple micro-nano rough struct...

Embodiment 3

[0033] After the surface of the pure titanium material was polished with sandpaper or mechanically polished, it was chemically polished with 15wt% HF and 30% HNO 3 After soaking in the aqueous solution for 30 seconds, the method of Example 1 was followed by ultrasonic cleaning with acetone, ethanol and water for 30min, and vacuum freeze-drying for 24h.

[0034] Then, a two-electrode system with titanium sheet as the anode and graphite as the cathode was used, and an aqueous solution containing 0.5wt% HF and 85wt% acetic acid was used as the electrolyte to perform electrochemical anodic oxidation at 40°C and a voltage of 150V / 2000Hz. The spacing is 5cm, and the time is 4h. The titanium sheet after electrochemical anodic oxidation treatment was ultrasonically cleaned in deionized water for 5 minutes according to the method of Example 1, the electrolyte was cleaned, and stored in absolute ethanol for 48 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com