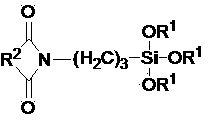

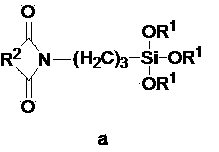

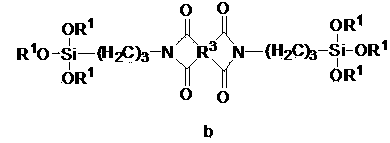

Preparation method of silane coupling agent with imide cycle structural unit

A monosilane coupling agent and imide ring-containing technology, which is applied in the field of silane coupling agent and preparation, can solve the problems of high cost and expensive desiccant, and achieve the effect of easy product, low cost and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The method for preparing silane coupling agent with phthalic anhydride, allylamine and triethoxysilane as raw material:

[0020] 1) Preparation of platinum-containing catalyst

[0021] Take 1g of chloroplatinic acid and dissolve it in anhydrous isopropanol, and make it constant in a 50ml volumetric flask, and the molar concentration is 0.0386mol / l.

[0022] 2) Preparation of imidization products

[0023] In a dry 500ml three-necked flask, add 14.8g (0.1mol) phthalic anhydride and 180ml glacial acetic acid, stir and dissolve, add 5.7g (0.1mol) allylamine, react at room temperature for 1h, heat to reflux for 4h, cool to After room temperature, add 170ml of water, heat to boil, cool to room temperature, a white solid precipitates out, filter with suction, wash with water, and recrystallize the solid with chloroform to obtain 17.2g of product with a yield of 92%, m.p.: 69~71 o c.

[0024] 3) Preparation of the final product

[0025] In a dry 250ml three-necked flask, ad...

Embodiment 2

[0027] The method for preparing silane coupling agent with norbornene monoanhydride, allylamine and triethoxysilane as raw material:

[0028] 1) Preparation of platinum-containing catalysts.

[0029] Take 1g of chloroplatinic acid and dissolve it in anhydrous isopropanol, and make it constant in a 50ml volumetric flask, and the molar concentration is 0.0386mol / l.

[0030] 2) Preparation of imidization products.

[0031] In a dry 500ml three-neck flask, add 16.4g (0.1mol) norbornene monoanhydride and 180ml glacial acetic acid, stir and dissolve, add 5.7g (0.1mol) allylamine, react at room temperature for 1h, heat to reflux for 24h, and cool to After room temperature, 170ml of water was added, heated to boiling, cooled to room temperature, a light yellow solid precipitated out, suction filtered, washed with water, and the solid was recrystallized with petroleum ether to obtain 8.1g of the product with a yield of 40%.

[0032] 3) Preparation of the final product.

[0033] In a...

Embodiment 3

[0035] 1) Preparation of platinum-containing catalysts.

[0036] Take 1g of chloroplatinic acid and dissolve it in anhydrous isopropanol, and make it constant in a 50ml volumetric flask, and the molar concentration is 0.0386mol / l.

[0037] 2) Preparation of imidization products.

[0038] In a dry 500ml three-neck flask, add 14.7g (0.05mol) biphenyltetraic dianhydride and 300ml glacial acetic acid, stir and dissolve, add 5.7g (0.1mol) allylamine, react at room temperature for 1h, heat to reflux for 4h, cool After reaching room temperature, 300ml of water was added, heated to boiling, cooled to room temperature, a white solid precipitated out, suction filtered, washed with water, and the solid was recrystallized with chloroform / acetone to obtain 16.7g of the product with a yield of 90%.

[0039] 3) Preparation of the final product.

[0040] In a dry 500ml three-necked flask, add 1.86g (0.005mol) of imidization product and 300ml of benzene, stir and add 0.12ml of platinum-conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com