A two-component agricultural machinery anti-corrosion decorative finish paint and preparation method thereof

A two-component technology for agricultural machinery, applied in the field of paint, can solve problems such as health problems and high prices, and achieve the effects of improved reactivity, uniform molecular weight distribution, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

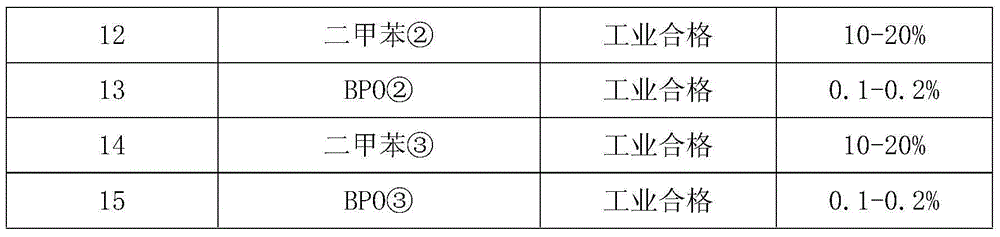

Examples

Embodiment 1

[0052] Embodiment 1 prepares YC-1 resin

[0053] 1. YC-1 resin formula

[0054]

[0055]

[0056] 2. YC-1 resin preparation process

[0057] (1) Add pentaerythritol, phthalic anhydride, maleic anhydride, trans-2-butenoic acid, benzoic acid, unsaturated fatty acid, dibutyltin oxide, xylene ( reflux) into the reactor, close the lid of the reactor, take 1-2 hours to raise the temperature to 180±2°C and keep the esterification for 2 hours, and then take 1-2 hours to raise the temperature to 200±2°C to keep the esterification until the acid value is ≤20mgKOH / g (solid ), then lower the temperature to below 140°C and add xylene ① to dilute to obtain the basic alkyd resin for later use.

[0058] (2) Add BPO① and styrene in component 2 into the batching tank according to the formula amount, mix well and set aside.

[0059] (3) Add the homogeneously mixed monomer into the basic alkyd resin, raise the temperature to 140±2°C and keep the copolymerization for 2.5-3 hours, then dir...

Embodiment 2

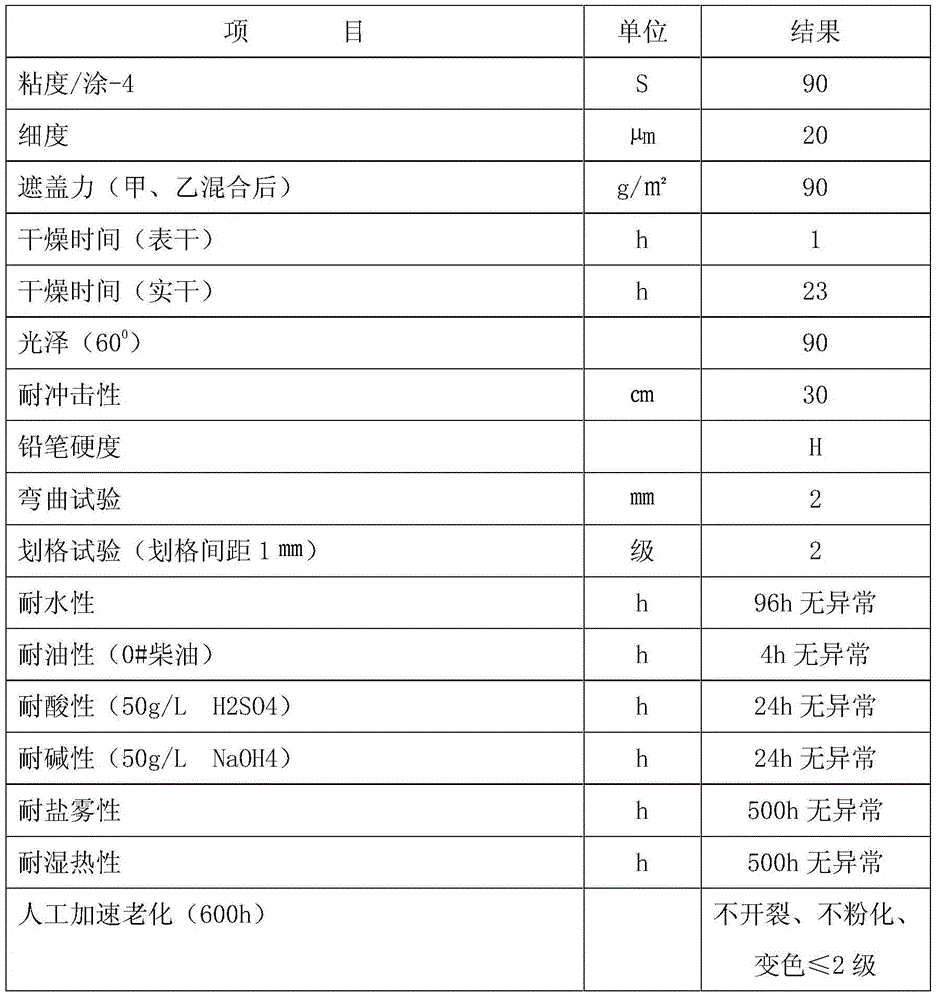

[0060] Embodiment 2 prepares main paint

[0061] 1. Main paint formula

[0062] Main paint formula

[0063] serial number

raw material name

Specification

Weight (kg)

1

YC-1 resin

self made

74

2

Wetting and dispersing agent

BYK-ATU

0.4

3

Organic bentonite

801-A

0.3

4

Phthalocyanine blue

BS

4.1

5

Titanium dioxide

ATR-312

9.7

6

light yellow powder

surface treatment

0.2

7

Modified filler

self made

5

8

leveling agent

BYK-306

0.3

9

Hemings, 5500

0.4

10

metal drier

Cobalt isooctanoate, isooctanoate

1

[0064]

Manganese equal proportion compound

11

Anti-skinning agent

841

0.2

12

Organotin

10%

0.2

13

DBE

Industrial Qualified

2

14

sec-butyl ester

Industrial Quali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com