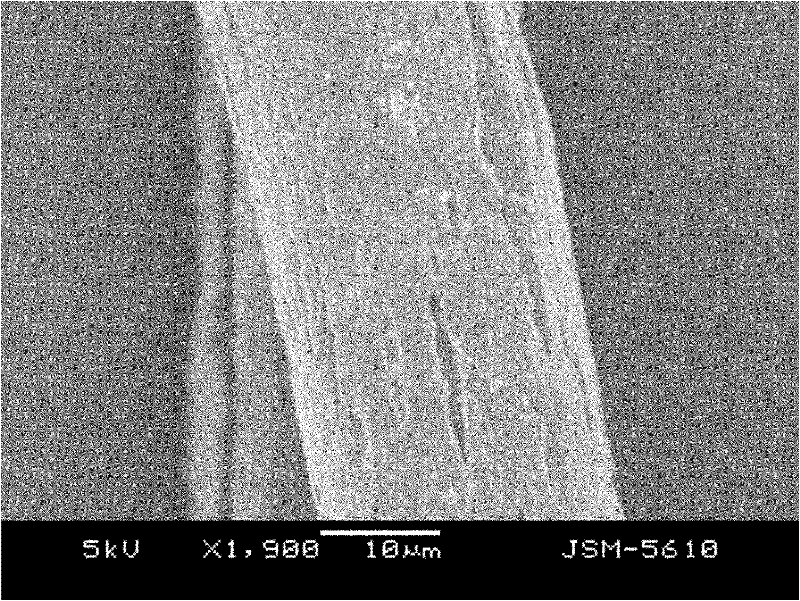

Microporous photocatalyst bamboo charcoal polyester modified short fiber and preparation method thereof

A bamboo charcoal polyester and polyester modification technology, which is applied in the field of spinning, can solve the problems of insufficient moisture absorption effect, reduced efficacy, and can not be used continuously, and achieves the effects of strong adsorption, decomposition, sterilization, and strong absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

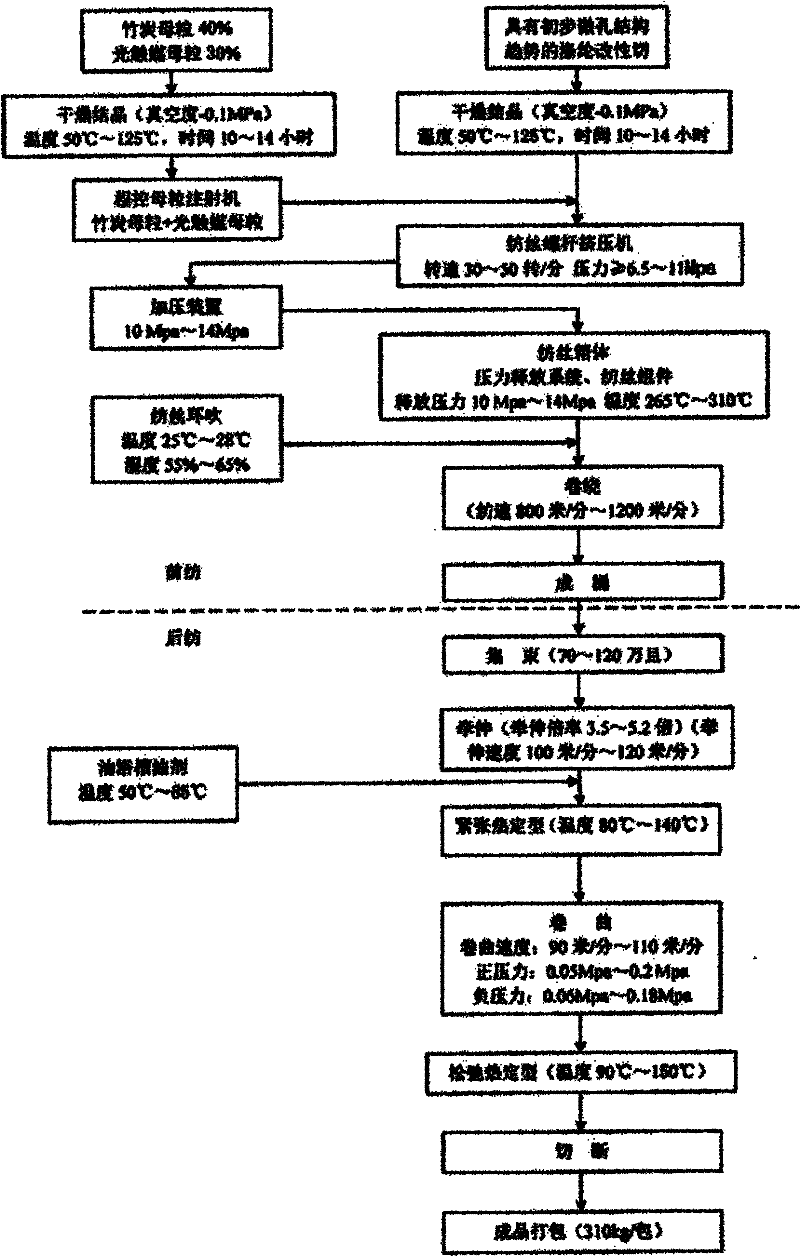

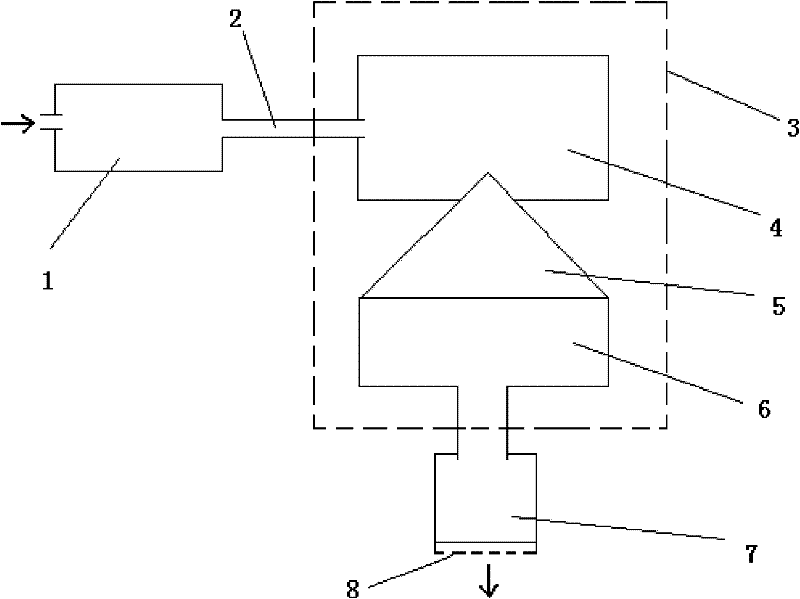

Method used

Image

Examples

Embodiment 1

[0076] 1. A method for producing polyester modified slices with a preliminary microporous structure tendency, comprising the following steps:

[0077] 1) First, purify terephthalic acid, ethylene glycol, polyethylene glycol, dimethyl isophthalate-5-sodium sulfonate and ethylene glycol antimony and triphenyl phosphate Fully mix and slurry in the slurry tank;

[0078] 2) Next, the mixed slurry is introduced into an esterification kettle for esterification reaction, and the esterification temperature is controlled at 260°C;

[0079] 3) again, in the polycondensation kettle, polyoxyethylene glycol and dimethyl isophthalate-5-sodium sulfonate and esterification reaction gained oligomer bishydroxyethyl terephthalate carry out reaction polycondensation and obtain a kind of having preliminary Polyester modified stock solution slurry with microporous structure trend, in which the polycondensation reaction temperature is 290°C, and the vacuum degree is 75Pa;

[0080] 4) Finally, extru...

Embodiment 2

[0129] 1. A method for producing polyester modified slices with a preliminary microporous structure tendency, comprising the following steps:

[0130] 1) First, purify terephthalic acid, ethylene glycol, polyethylene glycol, dimethyl isophthalate-5-sodium sulfonate and ethylene glycol antimony and triphenyl phosphate are mixed according to the following parts by weight ratio Fully mix and slurry in the slurry tank;

[0131] 2) Next, the mixed slurry is introduced into an esterification kettle for esterification reaction, and the esterification temperature is controlled at 200°C;

[0132] 3) again, in the polycondensation kettle, polyoxyethylene glycol and dimethyl isophthalate-5-sodium sulfonate and esterification reaction gained oligomer bishydroxyethyl terephthalate carry out reaction polycondensation and obtain a kind of having preliminary Polyester modified stock solution slurry with microporous structure trend, wherein the polycondensation reaction temperature is 245°C, ...

Embodiment 3

[0181] 1. A method for producing polyester modified slices with a preliminary microporous structure tendency, comprising the following steps:

[0182] 1) First, purify terephthalic acid, ethylene glycol, polyethylene glycol, dimethyl isophthalate-5-sodium sulfonate and ethylene glycol antimony and triphenyl phosphate are mixed according to the following parts by weight ratio Fully mix and slurry in the slurry tank;

[0183] 2) Next, the mixed slurry is introduced into an esterification kettle for esterification reaction, and the esterification temperature is controlled at 280°C;

[0184] 3) again, in the polycondensation kettle, polyoxyethylene glycol and dimethyl isophthalate-5-sodium sulfonate and esterification reaction gained oligomer bishydroxyethyl terephthalate carry out reaction polycondensation and obtain a kind of having preliminary Polyester modified stock solution slurry with microporous structure trend, wherein the polycondensation reaction temperature is 300°C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com