Ultraviolet-curable high temperature resistant pressure-sensitive adhesive and preparation method thereof

A pressure-sensitive adhesive, ultraviolet light technology, applied in the direction of adhesives, graft polymer adhesives, adhesive types, etc., can solve the problems of non-acrylate pressure-sensitive adhesive modification, etc., to achieve good high temperature shear performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

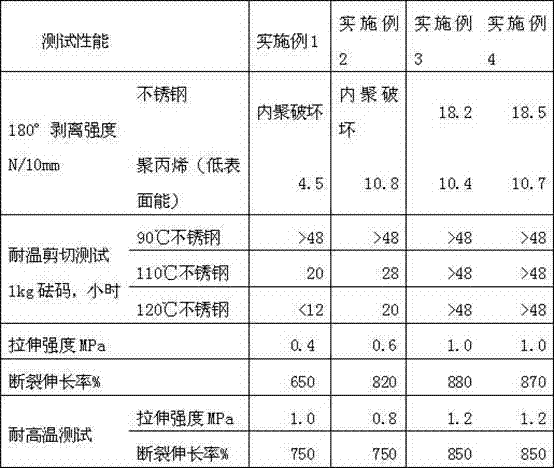

Examples

preparation example Construction

[0042] The present invention relates to the preparation of a high temperature resistant pressure sensitive adhesive, the preparation process comprising:

[0043] (a) A solvent-free UV-curable prepolymer consisting of

[0044] ① Contains about 80-98% (by weight) of soft monomer and 2-20% (by weight) of hard monomer. ;

[0045] Soft monomers include one or more mixtures of the following: ethyl acrylate, n-octyl acrylate, isooctyl acrylate, 2-ethylhexyl acrylate, n-butyl acrylate, tert-butyl acrylate, n-nonyl acrylate , isononyl acrylate, n-decyl acrylate, isodecyl acrylate, dodecyl acrylate.

[0046] Hard monomers include one or more of the following mixtures: acrylic acid, methacrylic acid, acrylonitrile, styrene

[0047] (b) one or more functional monomers

[0048] It is selected from:

[0049] ①A monofunctional monomer: (meth)acrylic acid, (meth)hydroxyethyl acrylate, (meth)hydroxypropyl acrylate, (meth)hydroxybutyl acrylate, acrylamide, N-vinyl caprolactam, N-vinylpyrr...

Embodiment 1

[0065] Add 0.15 parts of bis(multi)functional acrylate, 0.1~0.5 parts of photoinitiator to 100 parts of the above prepolymer, stir evenly and remove air bubbles, and apply it between two layers of transparent anti-adhesive films with a thickness of 1.0mm , and then placed in a 40W UV lamp for UV curing.

Embodiment 2

[0067] Add 5-15 parts of vinyl siloxane, 0.15 parts of (multi-) bifunctional acrylate, and 0.1-0.5 parts of photoinitiator to 100 parts of the above-mentioned prepolymer. After stirring evenly and removing air bubbles, spread it between two layers of transparent anti-adhesive films with a thickness of 1.0mm, and then put it into a 40W ultraviolet lamp for curing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com