Silicate green fluorescent powder used for LEDs and preparation method thereof

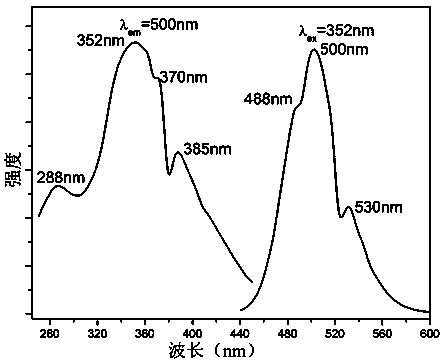

A green phosphor, silicate technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of high cost, high synthesis temperature, complex process, etc., and achieves improved luminous intensity, reduced calcination temperature, and high luminous intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

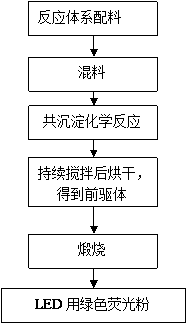

Method used

Image

Examples

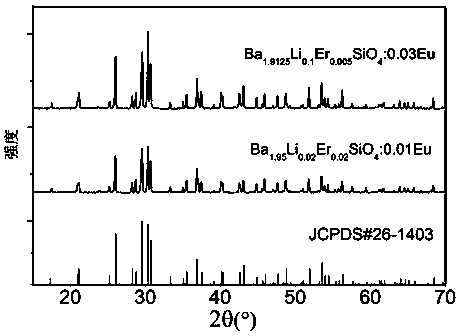

Embodiment example 1

[0026] According to chemical formula Ba 1.95 SiO 4 :Eu 2+ 0.01 , Li + 0.02 ,Er 3+ 0.02 Weigh BaCl 2 2H 2 O (A.R.) 1.95mol, LiCl (A.R.) 0.02mol, SiO 2 (nanoscale) 1mol, Eu 2 o 3 (99.99%)0.005mol, Er 2 o 3 (99.99%) 0.01mol;; then weigh 0.8wt% of the total mass of the above drugs, the surfactant polyethylene glycol; prepare the precipitant NH 4 HCO 3 solution, the concentration is 1.5mol / L; the weighed Eu 2 o 3 、Er 2 o3 Dissolve with an appropriate amount of hydrochloric acid, add an appropriate amount of deionized water and heat to 50°C for water bath treatment; add BaCl to the above solution 2 2H 2 O(A.R.), LiCl(A.R.), SiO 2 (nano-level), polyethylene glycol, stir simultaneously, add dropwise precipitating agent, adjust PH=9, continue to stir for 3 hours; Dry directly, obtain fluffy precursor; Precursor is placed in by hydrogen (H 2 ) in an atmosphere furnace providing a reducing atmosphere, the calcination temperature is 1150° C., and the calcination time i...

Embodiment example 2

[0028] According to chemical formula Ba 1.9125 SiO 4 :Eu 2+ 0.03 , Li + 0.1 ,Er 3+ 0.005 Weigh Ba (NO 3 ) 2 (A.R.) 1.9125mol, LiNO 3 (A.R.) 0.1mol, SiO 2 (nanoscale) 1mol, Eu 2 o 3 (99.99%)0.015mol, Er 2 o 3 (99.99%) 0.0025mol; then weigh the surfactant polyethylene glycol of 0.6wt% of the total mass of the above drug; prepare a precipitant (NH 4 ) 2 C 2 o 4 +NH 3 ·H 2 O solution with a concentration of 1mol / L; the weighed Eu 2 o 3 、Er 2 o 3 Dissolve with an appropriate amount of nitric acid, add an appropriate amount of deionized water and heat to 45°C for water bath treatment; add Ba(NO 3 ) 2 (A.R.), LiNO 3 (A.R.), SiO 2 (nano-level), polyethylene glycol, stir simultaneously, add dropwise precipitant, adjust PH=9, continue to stir for 3.5 hours; Dry directly, obtain fluffy precursor; 2 and N 2 ) in an atmosphere furnace providing a reducing atmosphere, the calcination temperature is 1200° C., and the calcination time is 3 hours to obtain the targ...

Embodiment example 3

[0030] According to chemical formula Ba 1.94 SiO 4 :Eu 2+ 0.05 , Li + 0.005 ,Er 3+ 0.005 Weigh BaCl 2 2H 2 O (A.R.) 1.94mol, LiCl (A.R.) 0.005mol, SiO 2 (nanoscale) 1mol, Eu 2 o 3 (99.99%)0.025mol Er 2 o 3 (99.99%) 0.0025mol; Then take by weighing the surfactant polyethylene glycol of 0.4wt% of the total mass of the above medicines; prepare precipitant (NH 4 ) 2 CO 3 solution, the concentration is 1mol / L; the weighed Eu 2 o 3 、Er 2 o 3 Dissolve with an appropriate amount of hydrochloric acid, add an appropriate amount of deionized water and heat to 40°C for water bath treatment; add BaCl to the above solution 2 2H 2 O(A.R.), LiCl(A.R.), SiO 2 (nanoscale), polyethylene glycol, stirring at the same time, dropwise adding precipitant, adjust PH=8, continue to stir for 3.5 hours; directly dry to obtain a fluffy precursor; Calcined in an atmosphere furnace with a neutral atmosphere, the calcination temperature is 1250° C., and the calcination time is 2.5 hours ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com