Recovery and utilization method of valuable metal sludge containing copper, nickel and cobalt

A valuable metal, copper-nickel technology, which is applied in the field of comprehensive utilization of resources and circular economy, can solve the problems that the "acid leaching-extraction-electrowinning" process technology cannot be solved, and achieves accelerated leaching reaction speed, fast extraction speed, and treatment. powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

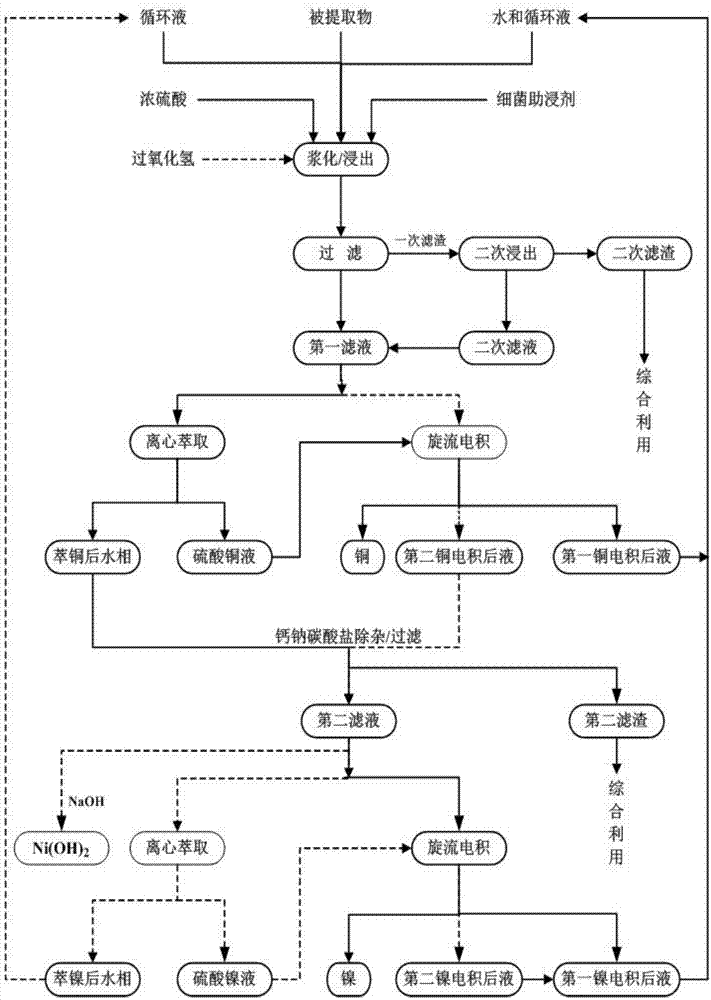

[0053] Embodiment 1 "bacterial leaching-centrifugal extraction of copper sulfate+swirl electrodeposition copper-centrifugal extraction of nickel sulfate+swirl electrodeposition nickel" includes the following steps:

[0054] A. Bacterial immersion aid:

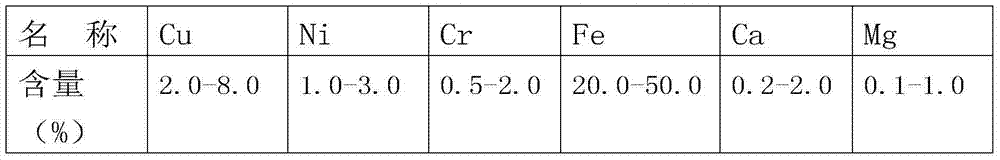

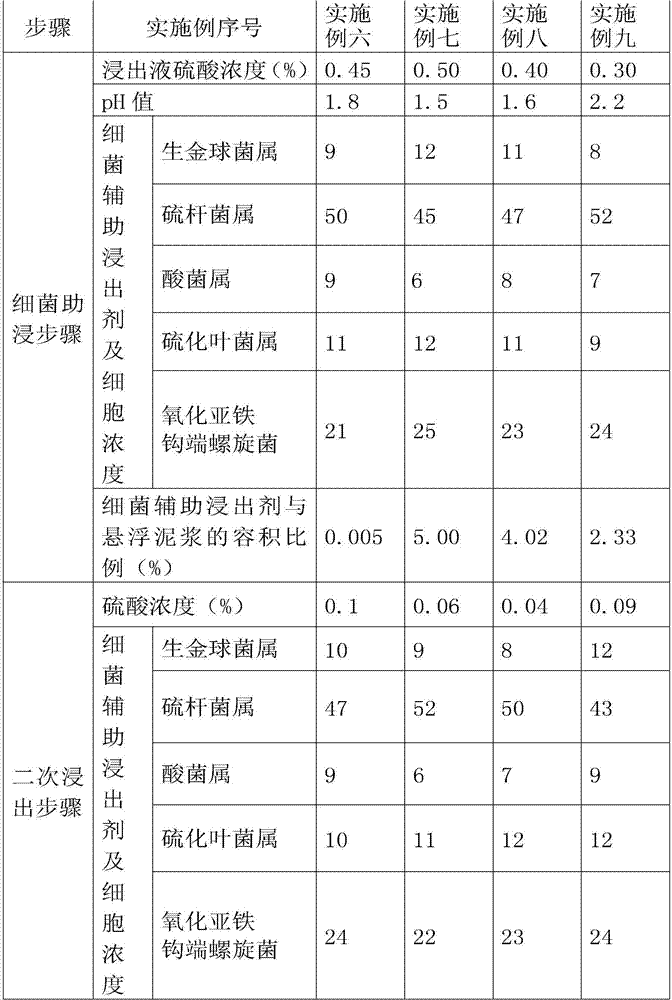

[0055] At room temperature, the slurry of the extract is mixed with an appropriate amount of 95%-98% sulfuric acid solution, bacterial auxiliary leaching agent and 30% hydrogen peroxide, and then the leachate is obtained. The pH value is controlled at 1.5-3.0, and the leachate is filtered. The first filtrate and the first filter residue are obtained; the volume ratio of the bacterial auxiliary leaching agent to the extract slurry is 0.005%-5.000%.

[0056] Bacterial auxiliary leaching agent is an optimized combination including one or several of the following bacteria, and the proportions after combination according to the cell concentration ratio per unit capacity are: 8%-12% of the genus Aureococcus, 45% of the genus Thiobaci...

Embodiment 2

[0069] Embodiment 2 "Bacteria-assisted immersion-swirl electrodeposited copper-centrifugal extraction of nickel sulfate", the process is as follows:

[0070] 1. Sludge pulping: Add electroplating sludge into the pulping tank, add water or circulating solution for stirring and pulping, so that the sludge and aqueous solution form a suspended slurry to facilitate leaching.

[0071] 2. Sulfuric acid dissolution and bacterial leaching aid: add an appropriate amount of 98% sulfuric acid and bacterial auxiliary leaching agent to the slurry at room temperature for stirring reaction and filtration to obtain the first filtrate and the first filter residue. The concentration of sulfuric acid in the leaching solution is adjusted at about 0.15%, and the pH value is controlled within 2.5; the composition of the bacterial auxiliary leaching agent: the genus Aureococcus with a cell concentration of 10%, the genus Thiobacillus with a cell concentration of 51%, and the genus with a cell concent...

Embodiment 3

[0078] Embodiment 3 "Bacterial leaching-centrifugal extraction of copper sulfate-swirl electrodeposited nickel", the process is as follows:

[0079] 1. Slag material grinding and slurrying: Grind the valuable metal slag material containing copper, nickel, cobalt, etc. to about 200 mesh and add it to the slurrying tank, add water or circulating solution for stirring and slurrying, so that the slag powder and the aqueous solution form a suspended slurry, for leaching.

[0080] 2. Sulfuric acid dissolution and bacterial leaching: add an appropriate amount of concentrated sulfuric acid solution, bacterial auxiliary leaching agent and 30% hydrogen peroxide to the slurry at room temperature for stirring reaction and filtration to obtain the first filtrate and the first filter residue. The concentration of sulfuric acid in the leaching solution is 0.2%, and the pH value is adjusted at 2.5-3.0 with soda; the composition of the bacterial auxiliary leaching agent: the cell concentration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com