Composite material of modified boride filled with epoxy resin

A technology of epoxy resin and composite materials, applied in the field of composite materials and high-performance composite materials, can solve the problems of high temperature and easy wear of pure epoxy resin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

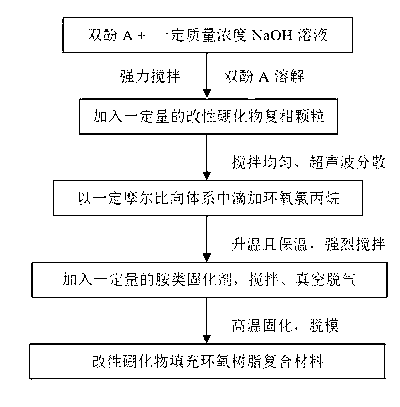

[0017] Add 25g of bisphenol A and 50ml of NaOH solution with a mass concentration of 10% into a 250ml round bottom flask, heat up and stir, dissolve at 70°C, and then cool down to 50°C. Add 2g of metal boride / Al surface modified by silane coupling agent 2 o 3 For multi-phase particle powder, the stirring rate is controlled at 800r / min. Under ultrasonic vibration, the powder particles are fully dispersed in the system; over. After the dropwise addition, the temperature was raised to 85° C., and after 6 hours of reaction, 2.5 g of fatty amine curing agent was added, and stirred at high speed for 20 minutes. After vacuum degassing, it was quickly injected into the mold, placed in an oven at 100°C for 5hrs, and at 130°C for 3hrs to obtain 28.59g of modified boride-filled epoxy resin composites. The test results show that the glass transition temperature Tg of the composite material is 108.8°C (under the same experimental conditions, the glass transition temperature Tg of epoxy ...

Embodiment 2

[0019] Add 50g of bisphenol A and 60ml of NaOH solution with a mass concentration of 20% into a 250ml round bottom flask, heat up and stir, dissolve at 70°C, and then cool down to 50°C. Add 5g of metal boride / Al whose surface is modified by titanate coupling agent 2 o 3 For multi-phase particle powder, the stirring rate is controlled at 900r / min. Under ultrasonic vibration, the powder particles are fully dispersed in the system; over. After the dropwise addition, the temperature was raised to 95°C, and after 2 hours of reaction, 6.5 g of aromatic amine curing agent was added, and stirred at high speed for 20 minutes. After vacuum degassing, it was quickly injected into the mold, placed in an oven at 80°C for 6hrs, and at 120°C for 4hrs to obtain 57.18g of modified boride-filled epoxy resin composites. The test results show that the glass transition temperature Tg of the composite material is 110.8°C; under dry friction room temperature conditions, when it is rubbed against ...

Embodiment 3

[0021] Add 80g of bisphenol A and 110ml of NaOH solution with a mass concentration of 15% into a 250ml round bottom flask, heat up and stir, dissolve at 70°C, and then cool down to 50°C. Add 8.9g of metal boride / Al whose surface is modified by aluminate coupling agent 2 o 3 For multi-phase particle powder, the stirring rate is controlled at 1000r / min. Under ultrasonic vibration, the powder particles are fully dispersed in the system; Drip finished. After the dropwise addition, the temperature was raised to 95°C, and after 2 hours of reaction, 10.5 g of aromatic amine curing agent was added, and stirred at high speed for 20 minutes. After vacuum degassing, it was quickly injected into the mold, placed in an oven at 120°C for 4hrs, and at 150°C for 2hrs to obtain 91.45g of modified boride-filled epoxy resin composites. The test results show that the glass transition temperature Tg of the composite material is 99.4°C; under dry friction at room temperature, when it is rubbed a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com