Ferrous sulfide dirt neutral complexing cleaning agent and preparation method thereof

A ferrous sulfide and cleaning agent technology, applied in chemical instruments and methods, detergent compounding agents, non-ionic surface active compounds, etc., can solve the problems of pickling corrosion, pitting corrosion, pitting corrosion, and unevenness of metal surfaces. Achieve the effects of facilitating equipment maintenance, reducing energy consumption, and improving mass and heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

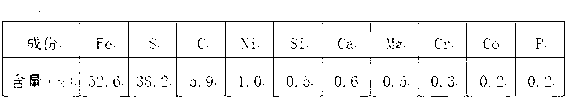

Image

Examples

Embodiment 1

[0042] Example 1 First, the raw materials were weighed according to the following components and weights: 6kg sodium gluconate, 9kg sodium salicylate, 22kg ammonium diethylenetriaminepentaacetate, 22kg sodium edetate, 43kg acrylic acid-itaconic acid Copolymer, 30kg sodium polyepoxysuccinate, 14kg sodium p-hydroxyphenylacetate, 5kg triethanolamine, 5kg hydrogen peroxide, 0.1kg sodium lauryl sulfate, 0.1kg polydimethyl silicone oil and 42kg water;

[0043] Then, above-mentioned raw material is prepared into ferrous sulfide dirt neutral complex cleaning agent according to the following steps:

[0044] 1. Under stirring, add ammonium diethylenetriaminepentaacetate, sodium ethylenediaminetetraacetate, acrylic acid-itaconic acid copolymer and sodium polyepoxysuccinate into the water in sequence; during the addition process, control the temperature not to exceed 25 ℃, react at room temperature for 60 minutes after adding the materials; then raise the temperature to 30°C, react for an...

Embodiment 2

[0047] Example 2 First, the raw materials were weighed according to the following components and weights: 8kg sodium gluconate, 7kg sodium salicylate, 24kg ammonium diethylenetriaminepentaacetate, 20kg sodium edetate, 46kg acrylic acid-itaconic acid Copolymer, 28kg sodium polyepoxysuccinate, 12kg sodium p-hydroxyphenylacetate, 6kg triethanolamine, 7kg hydrogen peroxide, 0.2kg sodium lauryl sulfate, 0.18kg polydimethyl silicone oil and 45kg water;

[0048] Then, above-mentioned raw material is prepared into ferrous sulfide dirt neutral complex cleaning agent according to the following steps:

[0049] 1, pH is adjusted to 7 with sodium hydroxide, all the other are with embodiment 1;

[0050] 2, with embodiment 1;

[0051] 3, with embodiment 1.

Embodiment 3

[0052] Example 3 First, the raw materials were weighed according to the following components and weights: 5kg sodium gluconate, 10kg sodium salicylate, 20kg ammonium diethylenetriaminepentaacetate, 23kg sodium edetate, 40kg acrylic acid-itaconic acid Copolymer, 25kg sodium polyepoxysuccinate, 15kg sodium p-hydroxyphenylacetate, 7kg triethanolamine, 3kg hydrogen peroxide, 0.15kg sodium lauryl sulfate, 0.15kg polydimethyl silicone oil and 40kg water;

[0053] Then, above-mentioned raw material is prepared into ferrous sulfide dirt neutral complex cleaning agent according to the following steps:

[0054] 1, pH is adjusted to 6 with sodium hydroxide, all the other are with embodiment 1;

[0055] 2, with embodiment 1;

[0056] 3, with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com