Method for preventing steel ladle slide mechanism from being opened accidentally

A technology of accidental opening and sliding mechanism, which is applied to equipment for feeding molten metal into molds, casting melt containers, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

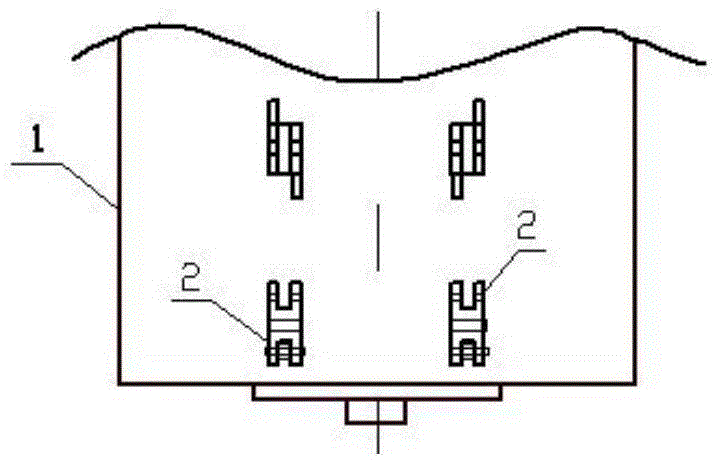

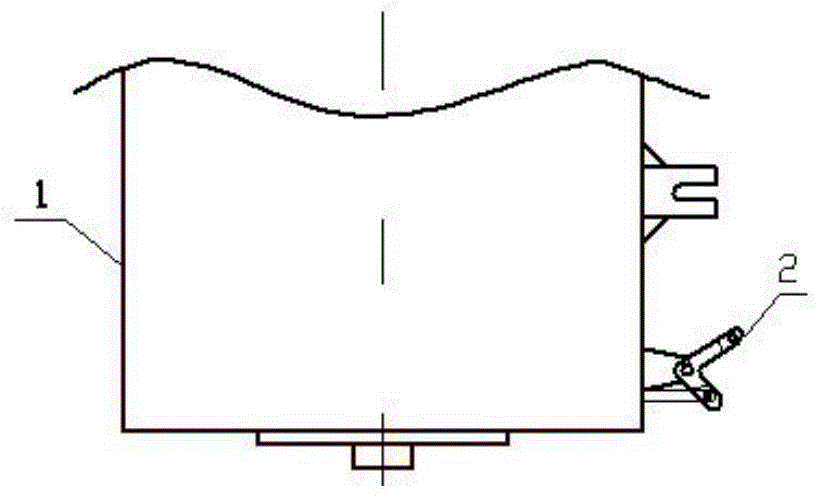

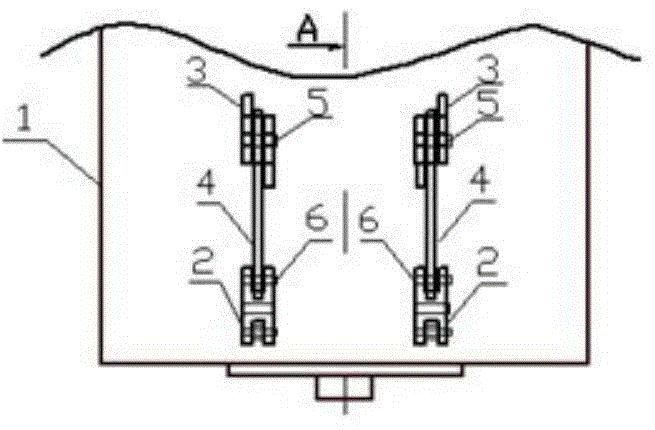

[0023] A method for preventing accidental opening of a ladle sliding mechanism, characterized in that the method includes the following steps:

[0024] a. Before the ladle is baked, remove the hydraulic cylinder from the ladle, install the support and protection rod, tap the steel after smelting, and lift the ladle to the designated position;

[0025] b. Remove the support and protection rod from the ladle, install the hydraulic cylinder, and complete the drainage of the ladle;

[0026] c. Pouring, then remove the hydraulic cylinder from the ladle, install the support and protection rod, and lift it back to the smelting workshop.

[0027] The support and protection rod is cylindrical, with a length of 800-1000 mm and a cross-sectional diameter of 50-60 mm.

[0028] The upper and lower parts of the support protection rod have holes respectively, the upper part is connected with the upper support of the ladle through pins, and the lower part is connected with the lower pull rod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com