A kind of antibacterial cobalt nickel chromium molybdenum alloy and preparation method thereof

A technology of cobalt-nickel-chromium-molybdenum alloy and nickel-chromium-molybdenum alloy, which is applied in the field of alloys, can solve the problems of difficult alloying, small solid solubility, and deterioration of thermal processing properties of materials, and achieve excellent antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention also discloses a preparation method of an antibacterial cobalt-nickel-chromium-molybdenum alloy, comprising the following steps:

[0029] a. Preparation of nickel-silver alloy: Ni99.9 electrolytic nickel and Ag-1 pure silver are melted in a vacuum electric arc furnace to obtain nickel-silver alloy NiAg 2 ;

[0030] b. Preparation of cobalt-cerium alloy: Melt 1# electrolytic cobalt and Ce-2N5B pure cerium in a vacuum electric arc furnace to prepare cobalt-cerium alloy CoCe 2 ;

[0031] c. NiAg prepared in step a 2 and the CoCe prepared in step b 2 Place it at the bottom of the copper crucible in the vacuum arc melting chamber, then place 1# electrolytic cobalt, Ni99.9 electrolytic nickel, JCr99A metal chromium and ASTM360 pure molybdenum on it; place a titanium ball in the center of the copper crucible, close the furnace door and evacuate to 5×10 -3 Below Pa and filled with pure argon to 0.8~1atm, then evacuated to 5×10 -3 Below Pa and filled with pur...

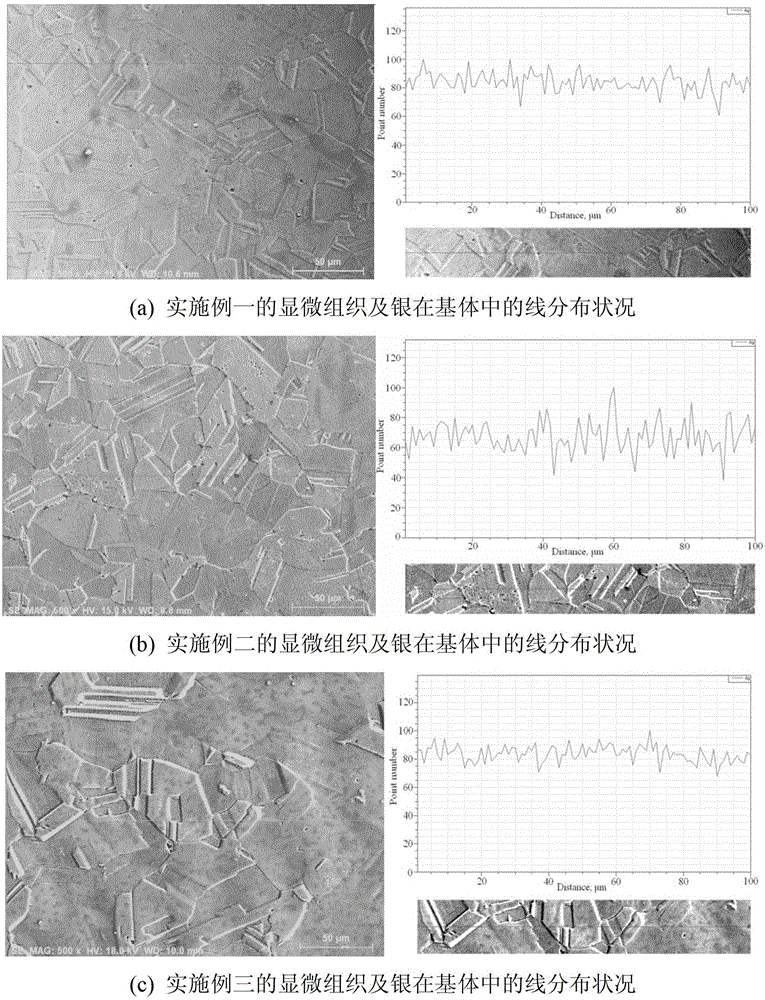

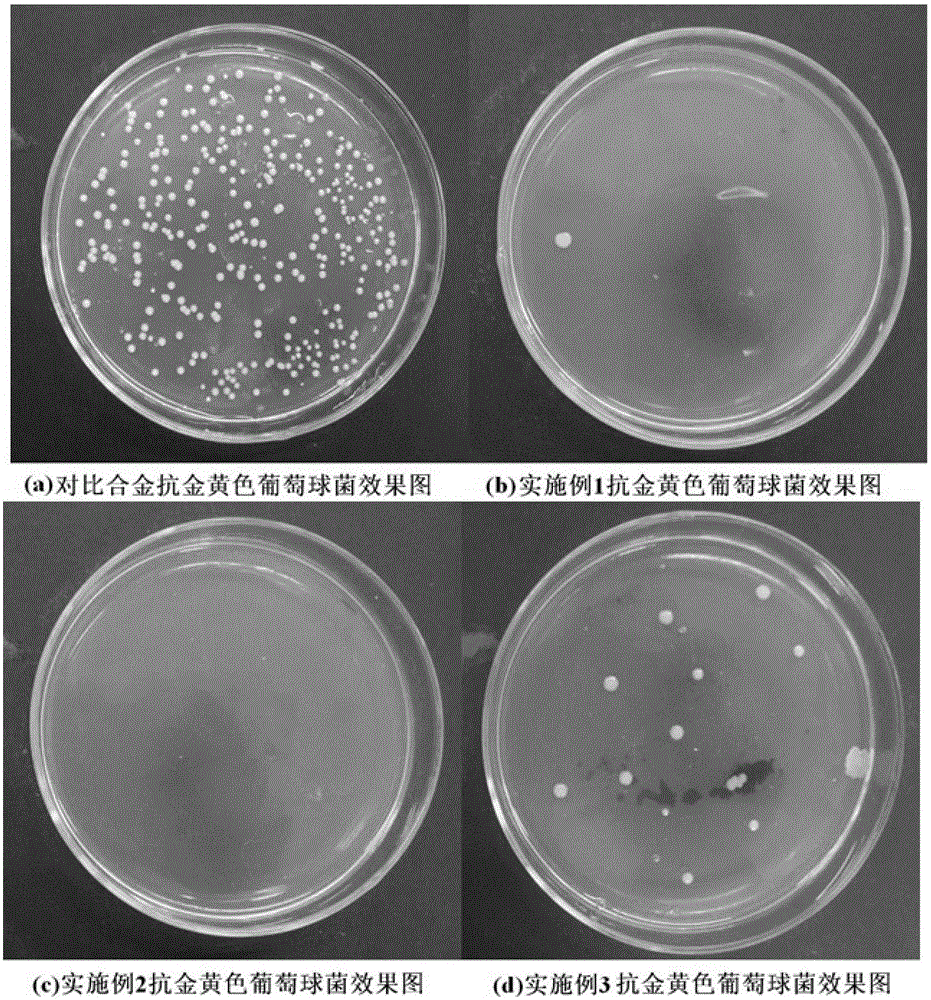

Embodiment 1

[0038] An antibacterial cobalt-nickel-chromium-molybdenum alloy of this embodiment, the alloy composition includes the following components by weight percentage: nickel 35.05%, chromium 19.79%, molybdenum 9.95%, carbon 0.008%, silicon 0.030%, iron 0.047%, aluminum 0.030% , copper 0.007%, silver 0.054%, cerium 0.038%, and the balance is cobalt.

[0039] A kind of preparation method of antibacterial cobalt-nickel-chromium-molybdenum alloy of the present embodiment, comprises the following steps:

[0040] a. Preparation of nickel-silver alloy: Ni99.9 electrolytic nickel and Ag-1 pure silver are melted in a vacuum electric arc furnace to prepare a nickel-silver alloy NiAg containing about 2% silver 2 ;

[0041] b. Preparation of cobalt-cerium alloy: Melt 1# electrolytic cobalt and Ce-2N5B pure cerium in a vacuum electric arc furnace to prepare cobalt-cerium alloy CoCe containing about 2% cerium 2 ;

[0042] c. NiAg prepared in step a 2 and the CoCe prepared in step b 2 Place ...

Embodiment 2

[0045] An antibacterial cobalt-nickel-chromium-molybdenum alloy of the present embodiment, the alloy composition includes the following components by weight percentage: nickel 36.49%, chromium 19.79%, molybdenum 9.95%, silver 0.076%, cerium 0.047%, carbon 0.008%, iron 0.047% , silicon 0.030%, copper 0.007%, aluminum 0.030%, and the balance is cobalt.

[0046] A kind of preparation method of antibacterial cobalt-nickel-chromium-molybdenum alloy of the present embodiment, comprises the following steps:

[0047] a. Preparation of nickel-silver alloy: Ni99.9 electrolytic nickel and Ag-1 pure silver are melted in a vacuum electric arc furnace to prepare a nickel-silver alloy NiAg containing about 2% silver 2 ;

[0048] b. Preparation of cobalt-cerium alloy: Melt 1# electrolytic cobalt and Ce-2N5B pure cerium in a vacuum electric arc furnace to prepare cobalt-cerium alloy CoCe containing about 2% cerium 2 ;

[0049] The raw materials are all in the form of small particles.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com