Hard-tissue bio-medical in-situ synthesized zirconium matrix composite material and preparation method thereof

A technique of tissue biology and in situ self-generation, applied in medical science, prosthesis, etc., can solve problems such as unfavorable bone healing and long-term stability of implants, insufficient matching of elastic modulus, stress shielding effect, etc., and achieve good biocompatibility properties, enhanced corrosion resistance, and increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

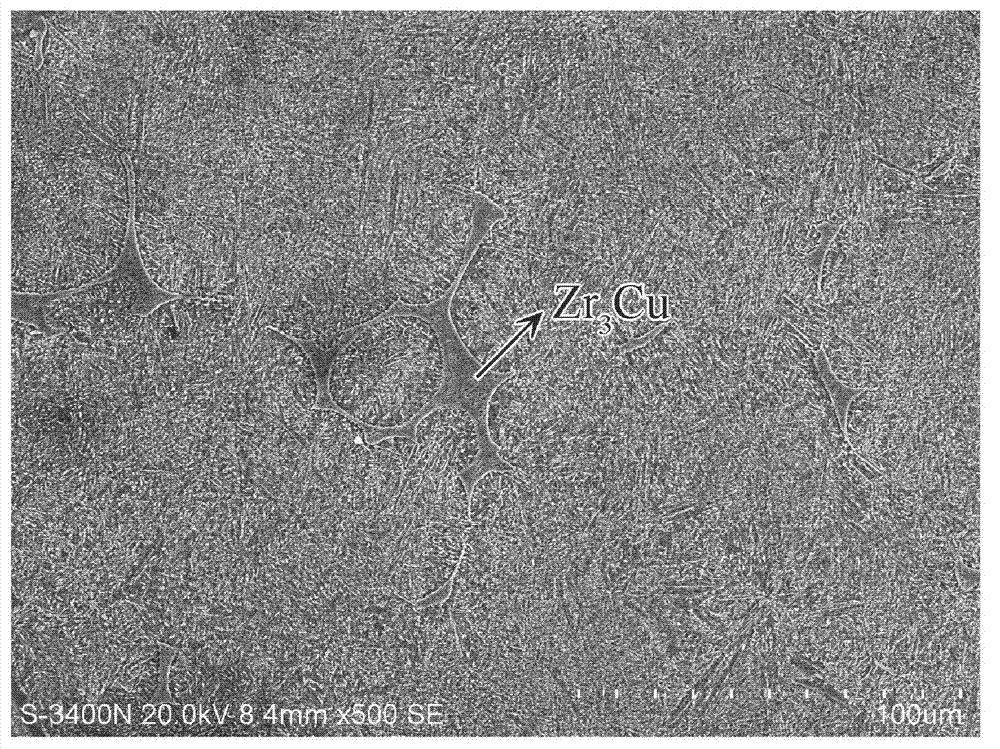

Embodiment 1

[0033] 1. Raw material formula: raw material components and weight percentages are: sponge zirconium 96.00%, copper 4.00%, niobium 0.1%; the purity of sponge zirconium, copper and niobium are all above 99%.

[0034] 2. Preparation method

[0035] (1) Weighing of raw materials, respectively weighing zirconium sponge, copper, and niobium according to the weight percentage of each raw material component; the particle size of raw materials is controlled below 2 cm;

[0036] (2) Mix the raw materials, mix the weighed raw materials evenly by stirring and mixing;

[0037] (3) Raw material smelting, put the uniformly mixed raw material into the crucible in the non-consumable vacuum electric arc furnace, and then vacuumize, the vacuum degree is 1×10 -2 ~1×10 -3 Pa; then pass in argon gas to wash; vacuumize and wash repeatedly for 2 to 4 times. Finally, smelting is carried out under the protection of inert gas, the smelting temperature is 2800-3000°C; the smelting voltage is 220V, th...

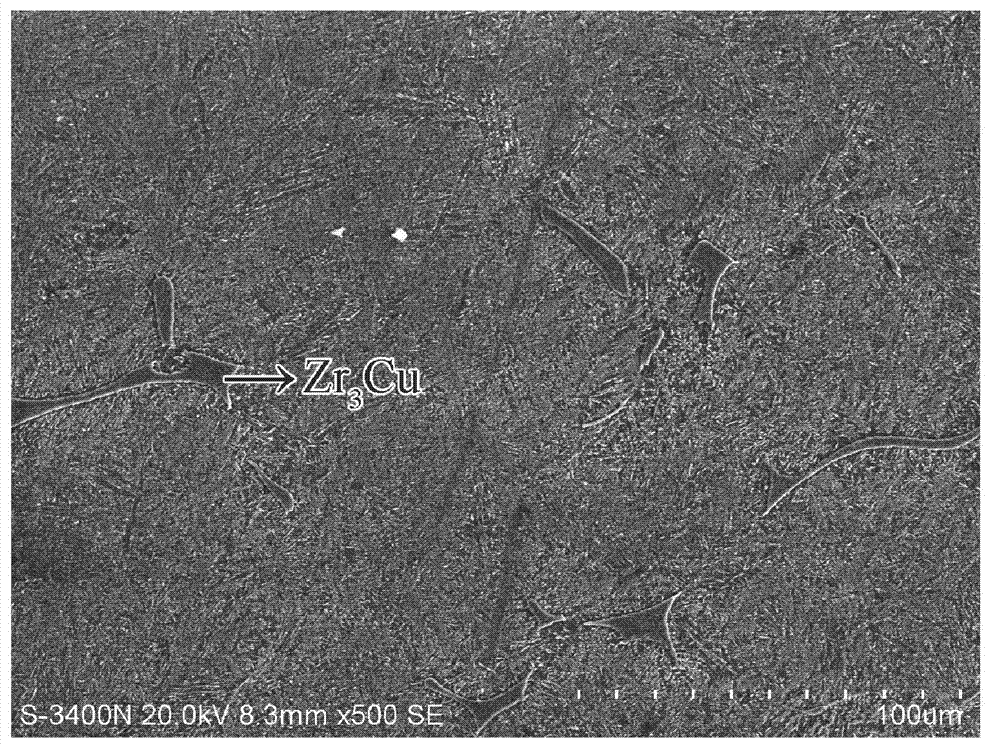

Embodiment 2

[0043] 1. Raw material formula: raw material components and weight percentages are: sponge zirconium 95.70%, copper 4.00%, niobium 0.30%; the purity of sponge zirconium, copper and niobium are all above 99%.

[0044] 2. Preparation method

[0045] (1) Weighing of raw materials, respectively weighing zirconium sponge, copper and niobium according to the weight percentage of each raw material component; the particle size of raw materials is controlled below 2 cm;

[0046] (2) Mix the raw materials, mix the weighed raw materials evenly by stirring and mixing;

[0047] (3) Raw material smelting, put the uniformly mixed raw material into the crucible in the non-consumable vacuum electric arc furnace, and then vacuumize, the vacuum degree is 1×10 -2 ~1×10 -3 Pa; then pass in argon gas to wash; vacuumize and wash repeatedly for 2 to 4 times. Finally, smelting is carried out under the protection of inert gas, the smelting temperature is 2800-2900°C; the smelting voltage is 220V, th...

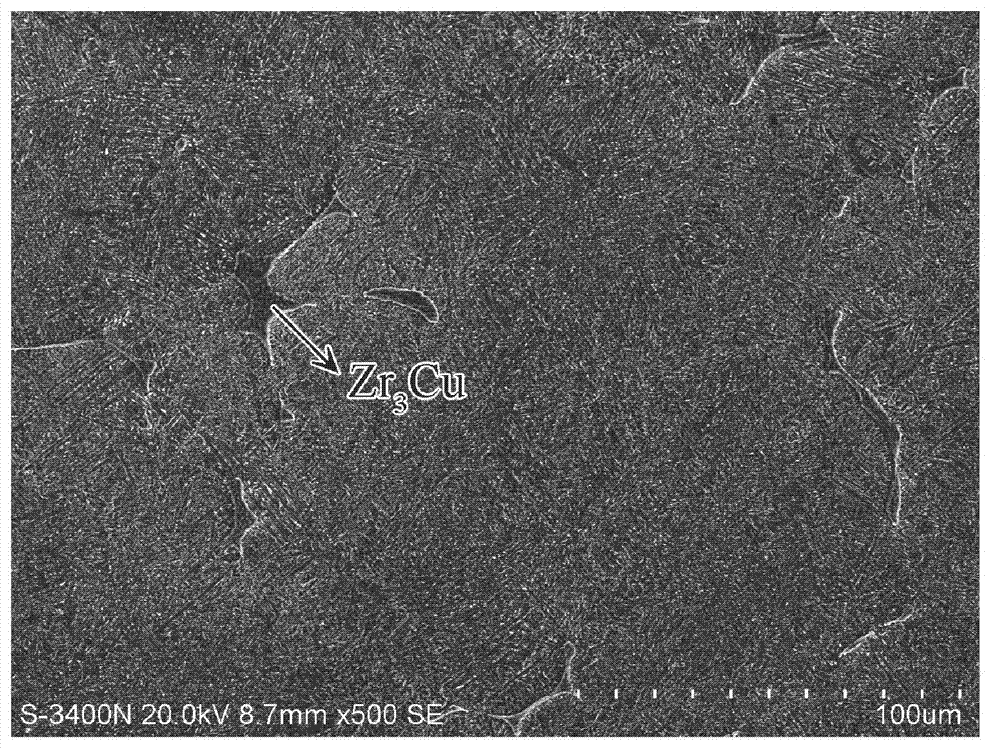

Embodiment 3

[0053] 1. Raw material formula: raw material components and weight percentages are: zirconium sponge 95.40%, copper 4.00%; niobium 0.60%, and the purity of zirconium sponge, copper and niobium are all above 99%.

[0054] 2. Preparation method

[0055] (1) Weighing of raw materials, respectively weighing zirconium sponge, copper and niobium according to the weight percentage of each raw material component; the particle size of raw materials is controlled below 2 cm;

[0056] (2) Mix the raw materials, mix the weighed raw materials evenly by stirring and mixing;

[0057] (3) Raw material smelting, put the uniformly mixed raw material into the crucible in the non-consumable vacuum electric arc furnace, and then vacuumize, the vacuum degree is 1×10 -2 ~1×10 -3 Pa; then pass in argon gas to wash; vacuumize and wash repeatedly for 2 to 4 times. Finally, melting is carried out under the protection of inert gas, the melting temperature is 2850-2950 °C; the melting voltage is 220 V,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com