Method for preparing spherical nanostructure tungsten/cobalt carbide compound powder

A nanostructure and composite powder technology, applied in the direction of nanotechnology, can solve the problems of increased gas consumption and energy consumption, reduced product performance, increased production costs, etc., to prevent excessive growth of grains, reduce processing and production costs, The effect of increasing the viscosity of the solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

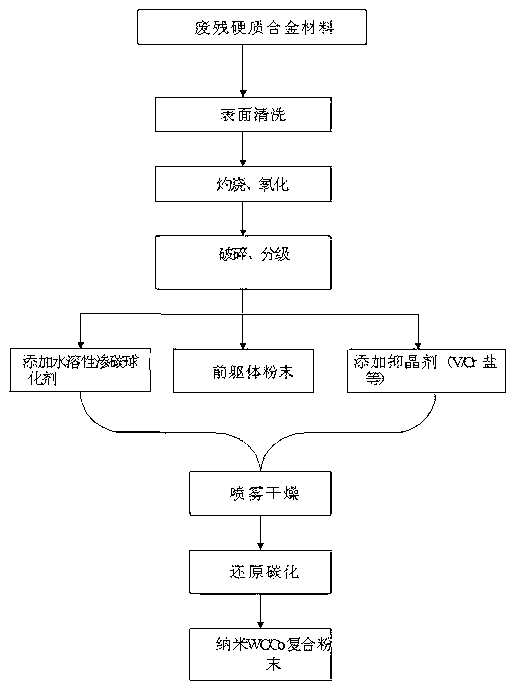

Method used

Image

Examples

example 1

[0045] Step 1: The starting material is the waste tungsten carbide / cobalt material in the production process or after use. The starting material is exposed to an oxygen-containing atmosphere and fired at a temperature of 850°C to clean the surface of the starting material The clean waste residue raw materials can be fully oxidized; the oxidized waste tungsten carbide / cobalt is further crushed, and the precursor powder of tungsten-cobalt composite oxide is obtained after oxidation and crushing;

[0046] Step 2: select 95kg of the precursor powder obtained in step 1, dissolve 3kg of starch and 2kg of water-soluble chromium salt in water with a quality of 300kg, and prepare a mixed aqueous solution;

[0047] Step 3: The mixed aqueous solution of step 2 must be subjected to rapid spray drying to obtain ultrafine compound salt powder;

[0048] Step 4: The powder material obtained after step 3 needs to undergo reduction synthesis and carbon adjustment at a temperature of 900°C to pr...

example 2

[0051] Step 1: The starting material is the waste tungsten carbide / cobalt material in the production process or after use. The starting material is exposed to an oxygen-containing atmosphere and fired at a temperature of 880°C to clean the surface of the starting material The clean waste residue raw materials can be fully oxidized; the oxidized waste tungsten carbide / cobalt is further crushed, and the precursor powder of tungsten-cobalt composite oxide is obtained after oxidation and crushing;

[0052] Step 2: select the precursor powder obtained in step 1 with a mass fraction of 93kg, dissolve 6kg of sugar and 1kg of water-soluble vanadium salt in water with a quality of 400kg, and prepare a mixed aqueous solution;

[0053] Step 3: The mixed aqueous solution of step 2 must be subjected to rapid spray drying to obtain ultrafine compound salt powder;

[0054] Step 4: The powder material obtained after step 3 needs to undergo reduction synthesis and carbon adjustment at a temper...

example 3

[0057] Step 1: The starting material is the waste tungsten carbide / cobalt material in the production process or after use. The starting material is exposed to an oxygen-containing atmosphere and fired at a temperature of 900°C to clean the surface of the starting material The clean waste residue raw materials can be fully oxidized; the oxidized waste tungsten carbide / cobalt is further crushed, and the precursor powder of tungsten-cobalt composite oxide is obtained after oxidation and crushing;

[0058] Step 2: 93.9 kg of the precursor powder obtained in step 1, 6 kg of polyethylene glycol (PEG) and 0.1 kg of water-soluble chromium salt were dissolved in 300 kg of water to prepare a mixed aqueous solution;

[0059] Step 3: The mixed aqueous solution of step 2 must be subjected to rapid spray drying to obtain ultrafine compound salt powder;

[0060] Step 4: The powder material obtained after step 3 needs to undergo reduction synthesis and carbon adjustment at a temperature of 95...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com