Preparation method for high-density fine grain tungsten copper alloy

A tungsten-copper alloy, dense technology, applied in the field of powder metallurgy material preparation, can solve the problems of hindering tungsten-copper mechanical alloying, powder pollution, high equipment requirements, shorten sintering time, improve wettability, and reduce oxygen content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1: Prepare a tungsten-copper alloy whose standard composition is W (85%wt), Cu (15%wt), and its standard density is 16.40g / cm 3 , complete the following steps:

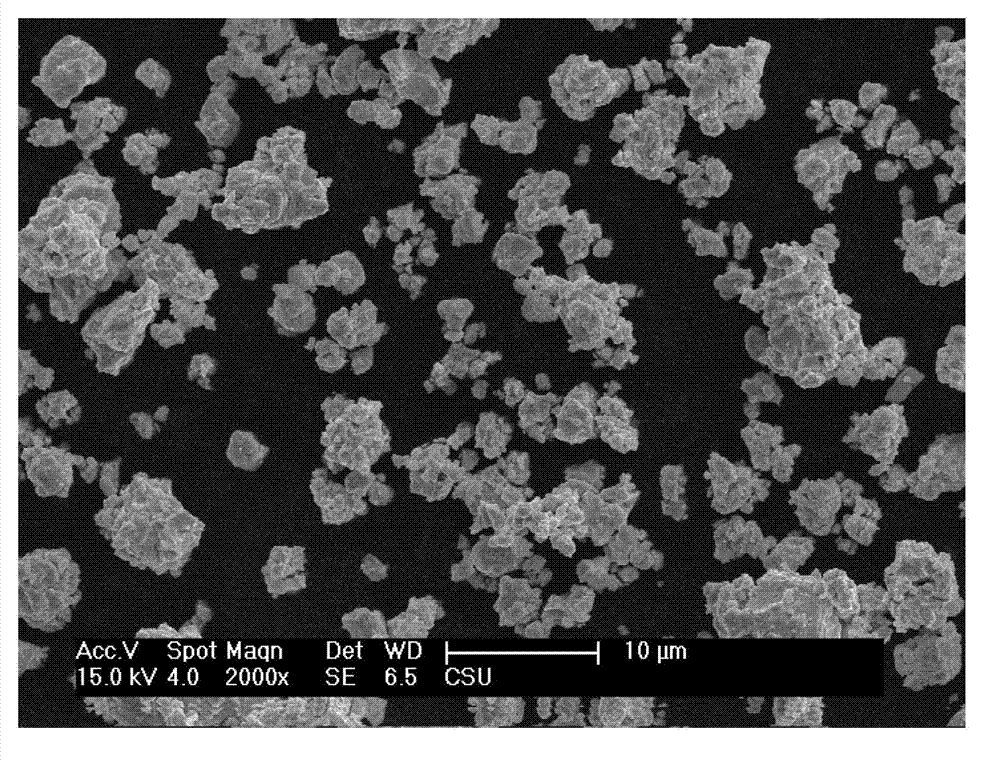

[0032] 1. Weigh 60g each of pure copper powder (particle size 5~100μm) and pure tungsten powder (particle size 2~15μm) for general industrial use, and carry out reduction treatment for 340g in a hydrogen atmosphere for 45min at a reduction temperature of 450 °C, 780 °C.

[0033] 2. Mix the reduced copper powder and tungsten powder on a mixer for 2 hours.

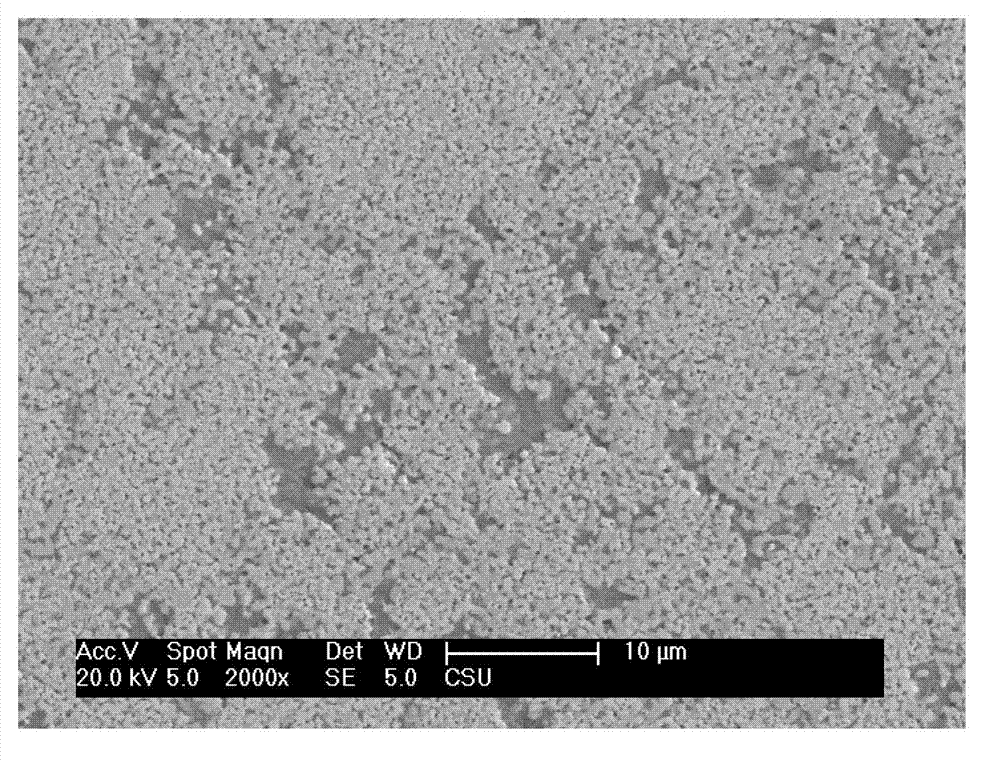

[0034]3. Put the tungsten-copper mixed powder into a stainless steel ball mill tank, add 6kg of stainless steel balls (the ratio of ball to material is 15:1), and vacuumize the ball mill tank to 10 -2 Pa, then feed pure argon gas, seal it with a cover, carry out high-speed dry milling on a ball mill, and after ball milling at a ball milling speed of 450r / min for 20h, open the ball milling tank in an argon atmosphere glove box, and add 40ml to the...

Embodiment 2

[0039] Example 2: Preparation of a tungsten-copper alloy whose standard composition is W (70%wt), Cu (30%wt), and whose standard density is 14.28g / cm 3 , follow the steps below to complete.

[0040] 1. Weigh 280g each of pure copper powder (particle size 5~100μm) and pure tungsten powder (particle size 2~15μm) for general industrial use, and carry out reduction treatment for 120g in a hydrogen atmosphere for 45min at a reduction temperature of 450 °C, 780 °C.

[0041] 2. Mix the reduced copper powder and tungsten powder on a mixer for 2 hours.

[0042] 3. Put the tungsten-copper mixed powder into a stainless steel ball mill jar, add 4.8kg of stainless steel balls (the ratio of ball to material is 12:1), seal it with a cover, and evacuate to 10 -2 Pa, then pass into pure argon gas, carry out high-speed dry milling on the ball mill, after ball milling with the ball milling speed of 400r / min for 15h, open the ball mill jar in the glove box of argon atmosphere, add 50ml absol...

Embodiment 3

[0047] Example 3: Preparation of a tungsten-copper alloy whose standard composition is W (55%wt), Cu (45%wt), and whose standard density is 12.65g / cm 3 , follow the steps below to complete.

[0048] 1. Weigh 260 and 140g of pure copper powder (particle size: 5~100μm) and pure tungsten powder (particle size: 2~15μm) for general industrial use respectively, and carry out reduction treatment in hydrogen atmosphere for 30 minutes, and the reduction temperature is 450 °C, 780 °C.

[0049] 2. Mix the reduced copper powder and tungsten powder on a mixer for 2 hours.

[0050] 3. Put the tungsten-copper mixed powder into a stainless steel ball mill jar, add 4kg of stainless steel balls (the ratio of ball to material is 10:1), seal it with a cover, and evacuate to 10 -2 Pa, then feed pure argon gas, perform high-speed dry milling on a ball mill, and after ball milling at a ball milling speed of 400r / min for 20h, open the ball milling tank in a glove box filled with argon atmosphere...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Actual density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Actual density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com