Epoxy resin silica sol, epoxy resin organic-inorganic nano hybrid material and preparation method thereof

An epoxy resin curing and epoxy resin technology, which is applied in the field of epoxy resin silica sol preparation, can solve problems such as poor processability and poor particle dispersion stability, and achieve the effects of excellent insulation performance, uniform and stable dispersion, and stable material quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: a kind of epoxy resin silica sol that this embodiment provides, it is made of following components: epoxy resin, organosilicon, silane coupling agent, organic solvent, ammoniacal liquor, wherein the mole of each component The ratio is: epoxy resin 1: organosilicon 0.1-2: silane coupling agent 0.01-2: organic solvent 0.9-18: ammonia water 0.001-0.06.

[0027] The organosilicon is one of methyl orthosilicate, ethyl orthosilicate and butyl orthosilicate.

[0028] The organic solvent is one of N,N-dimethylformamide, acetone, butanone and toluene.

[0029] The silane coupling agent is γ-aminopropyltriethoxysilane, γ-glycidyloxypropyltrimethoxysilane, γ-(methacryloyloxy)propyltrimethoxysilane, N- One of (β-aminoethyl)-γ-aminopropyltrimethoxysilane.

[0030] Described epoxy resin is bisphenol A type epoxy resin, bisphenol F type epoxy resin, bisphenol S type epoxy resin, bisphenol AD type epoxy resin, novolak type epoxy resin, cycloaliphatic epoxy resin One ...

Embodiment 2

[0041] Embodiment 2: This embodiment provides a kind of epoxy resin silica sol and preparation method thereof, and its step is basically the same as embodiment 1, and its difference is:

[0042] Epoxy resin silica sol component and preparation method thereof, specifically the following proportions and steps:

[0043] (1) Take 7.6ml (0.034mol) of tetraethyl orthosilicate and dissolve it in 60ml (0.78mol) of N,N-dimethylformamide to make a mixed solution;

[0044] (2) Measure 10ml (0.13mol) of N,N-dimethylformamide in a three-necked flask, add 0.936ml (0.0040mol) of γ-aminopropyltriethoxysilane and 0.12ml of ammonia water to prepare into a mixed solution;

[0045] (3) Under the condition of mechanical stirring, through the dropping funnel, at room temperature, in the solution prepared in step (2), slowly drop into the mixed solution prepared in step (1), the rate of addition is controlled to be 15- 20s / drop, the stirring speed is 100-200r / min, after the dropwise addition is co...

Embodiment 3

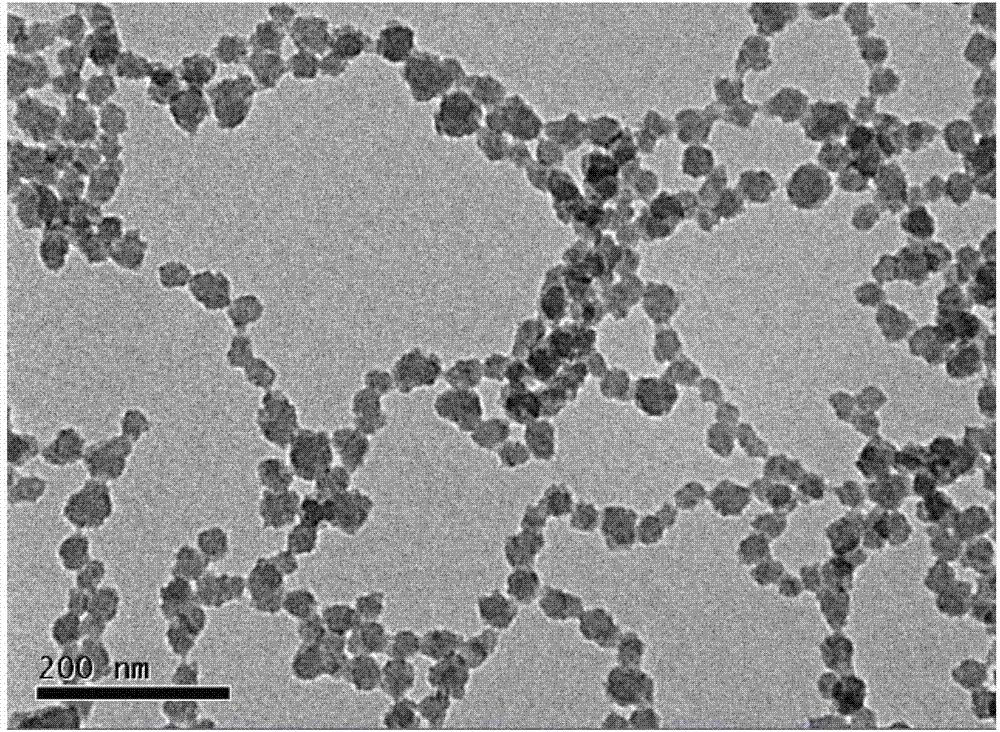

[0051] Embodiment 3: see figure 1 , the epoxy resin silica sol provided in the present embodiment and preparation method thereof, its steps are basically the same as in Embodiment 1, 2, and its difference is:

[0052] Components and preparation methods of epoxy resin silica sol, which are specifically the following ratios and steps:

[0053] (1) Take 7.6ml (0.084mol) of tetraethyl orthosilicate and dissolve it in 60ml (0.76mol) of N,N-dimethylformamide to make a mixed solution;

[0054] (2) Measure 10ml (0.13mol) of N,N-dimethylformamide in a three-necked flask, add 0.936ml (0.011mol) of γ-aminopropyltriethoxysilane and 0.32ml of ammonia water to prepare into a mixed solution.

[0055] (3) Under the condition of mechanical stirring, slowly drop the mixed solution prepared in step (1) into the solution prepared in step (2), after the addition is completed, add epoxy resin, and stir for 10 ~ 12 hours;

[0056] (4) Transfer the mixed solution prepared in step (3) to a beaker,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com