Preparation method and application of graphene oxide composite zinc-cobalt-nickel multi-metal hydroxide ternary composite material

A composite material, the technology of zinc nitrate hexahydrate, which is applied in the field of preparation of graphene oxide composite zinc-cobalt-nickel multi-metal hydroxide ternary composite materials, can solve the weakened electrochemical performance and the easy aggregation of hexagonal nanosheets and other problems, to achieve the effect of simple preparation method, favorable electrochemical performance and high diffusion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

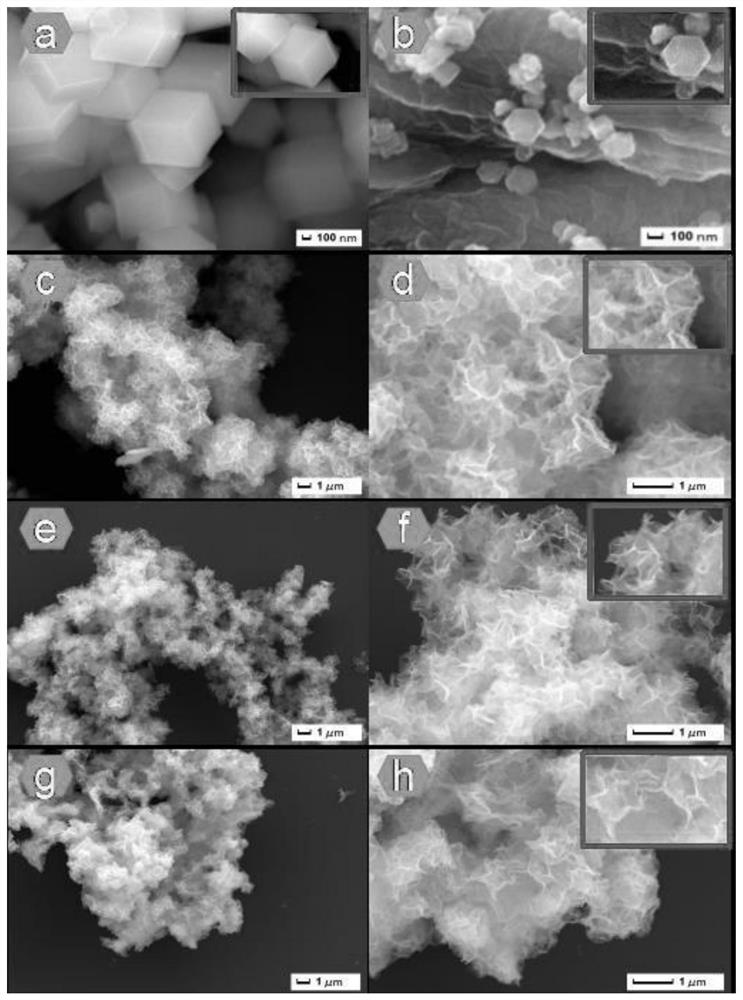

Embodiment 1

[0029] 656mg of 2-methylimidazole and 582mg of zinc nitrate hexahydrate were dissolved in 50ml of methanol respectively, and under the action of magnetic stirring, the methanol solution containing 656 mg of 2-methylimidazole was added dropwise to the solution containing 582mg of zinc nitrate hexahydrate. In the methanol solution, keep magnetic stirring for 30 min after the drop is complete. After the stirring was completed, pure ZIF-8 was prepared by aging at room temperature. After aging for 24 hours, the samples were finally collected by centrifugation, washed three times alternately with water and ethanol, and dried at 60°C for 12 hours to obtain pure ZIF-8.

Embodiment 2

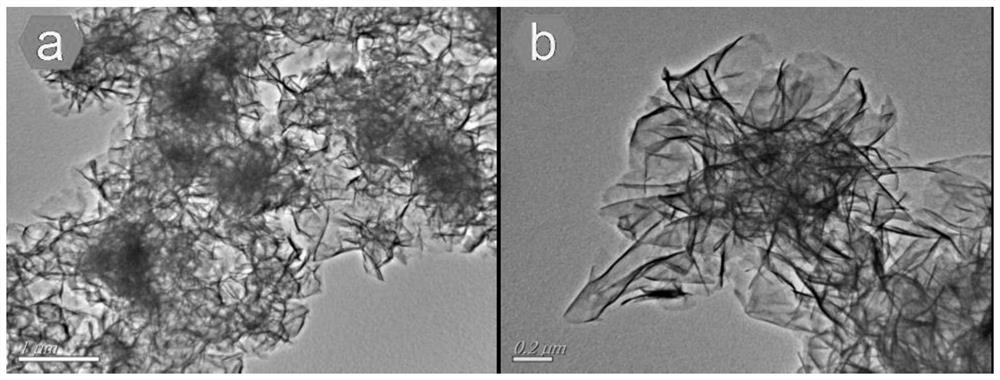

[0031] A preparation method of GO / Zn-Co-Ni LDHs ternary composite material, comprising:

[0032] Dissolve 15 mg of graphene oxide synthesized by the improved Hummers method in 50 mL of methanol, and ultrasonicate for 1 hour to form a homogeneous solution. Weigh 582 mg of zinc nitrate hexahydrate and add to the above solution. After ultrasonication for 1 hour, the sample was taken out, and slowly and gradually added dropwise into 50 ml of a methanol solution containing 656 mg of 2-methylimidazole under magnetic stirring. After the addition was complete, magnetic stirring was performed for another 30 min, followed by aging at room temperature for 24 h. The final step is to collect the samples by centrifugation, wash alternately with water and ethanol three times, and dry at 60 °C for 12 h to obtain the precursor GO / ZIF-8.

[0033] Weigh 80 mg of the prepared template GO / ZIF-8 and add it into 100 mL of ethanol containing 200 mg of cobalt nitrate hexahydrate and 200 mg of nickel...

Embodiment 3

[0036] A preparation method of GO / Zn-Ni LDHs binary composite material, comprising:

[0037] Dissolve 15 mg of graphene oxide synthesized by the improved Hummers method in 50 mL of methanol, and ultrasonicate for 1 hour to form a homogeneous solution. Weigh 582 mg of zinc nitrate hexahydrate and add to the above solution. After ultrasonication for 1 hour, the sample was taken out, and slowly and gradually added dropwise into 50 ml of a methanol solution containing 656 mg of 2-methylimidazole under magnetic stirring. After the addition was complete, magnetic stirring was performed for another 30 min, followed by aging at room temperature for 24 h. The final step is to collect the samples by centrifugation, wash alternately with water and ethanol three times, and dry at 60 °C for 12 h to obtain the precursor GO / ZIF-8.

[0038] Weigh 80 mg of the prepared template GO / ZIF-8 and add it into 100 mL of ethanol containing 400 mg of nickel nitrate hexahydrate, stir for 3 min, and mak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com