Inorganic nano antibacterial plastic, and preparation method and application thereof in water supply pipe

A technology of inorganic nano and antibacterial plastics, applied in the field of plastics, can solve the problems of easy migration of antibacterial agents, decomposition failure, short antibacterial life, etc., and achieve the effect of facilitating transmission and dispersion of stress, solving agglomeration phenomenon, and high antibacterial efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

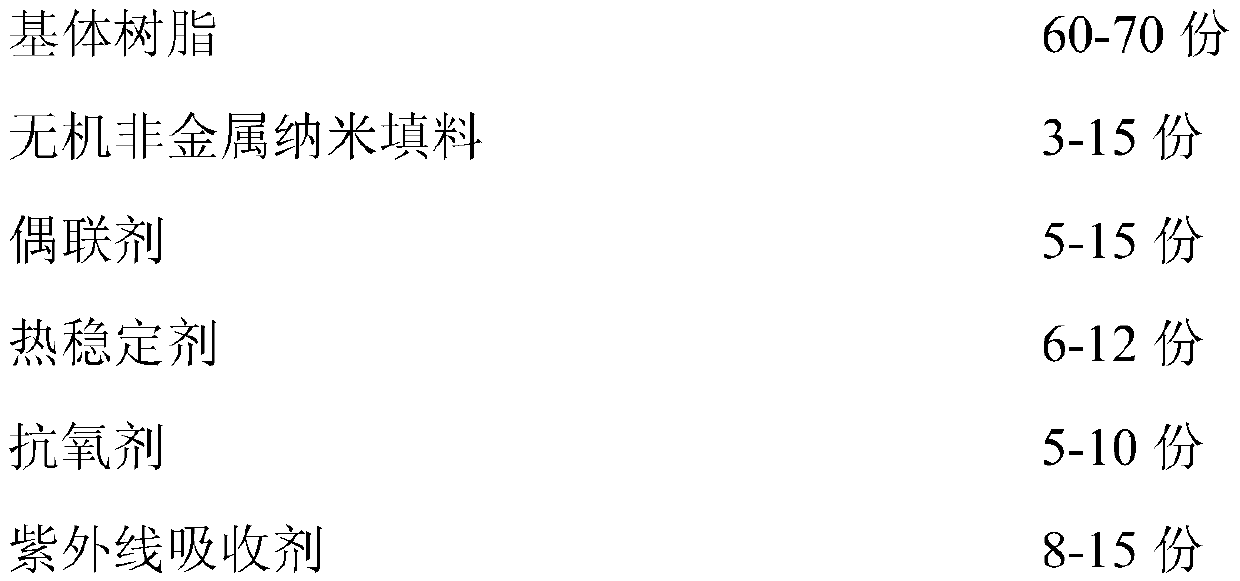

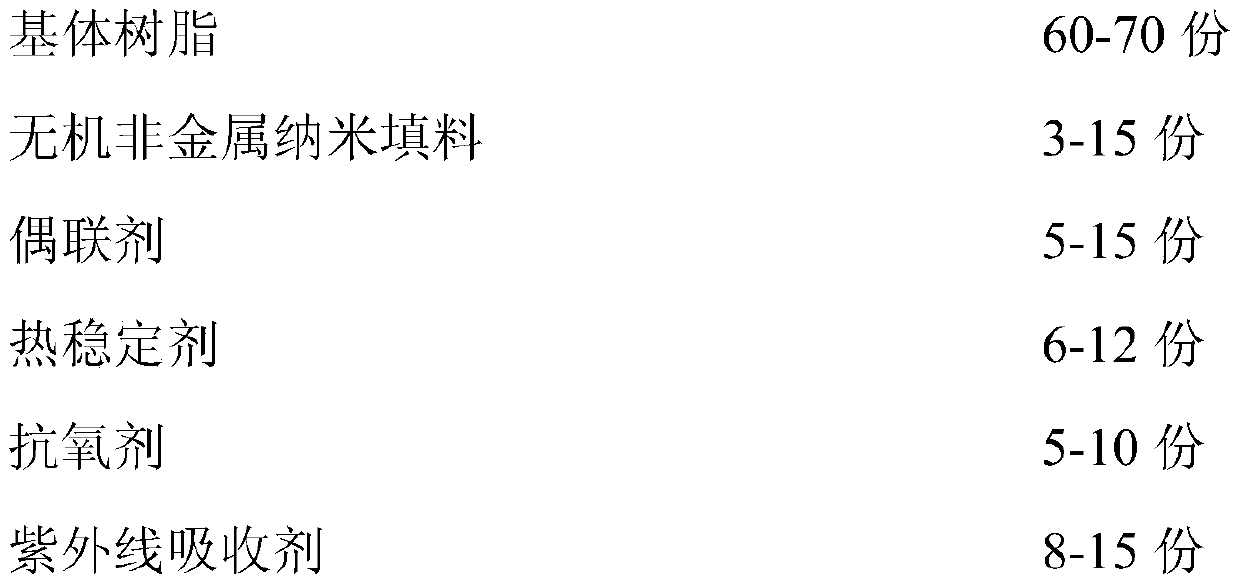

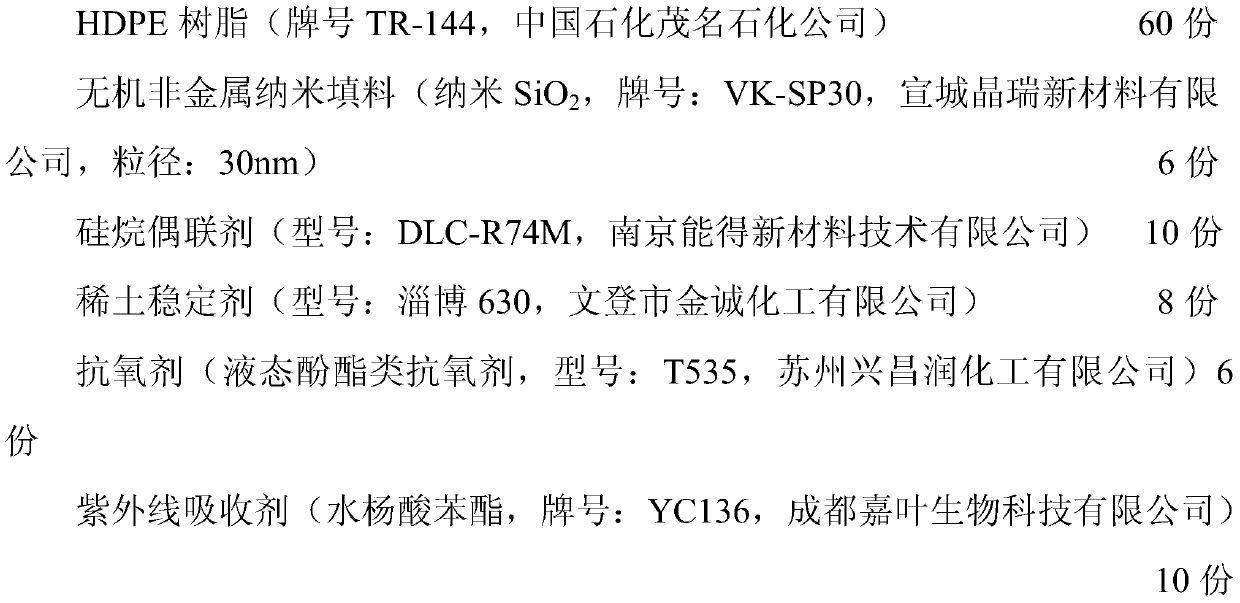

[0034] In parts by mass, with HDPE resin as the plastic base material, the raw material formula of inorganic nano antibacterial high-density polyethylene (HDPE) is as follows:

[0035]

[0036](1) The preparation method and processing of inorganic nanometer antibacterial agent are as follows:

[0037] First, disperse the inorganic non-metallic nano-filler in trichlorethylene solvent (Beijing Kexi Century Technology Co., Ltd.), make a slurry with a mass fraction of 15%, and use a magnetic stirring water bath (model: DF-101S, Henan Qiuzuo Instrument Equipment Co., Ltd.) heated and stirred evenly, according to the above formula, add a coupling agent, react at this temperature for 2 hours, then heat the slurry to reflux at 100 ° C, evaporate the solvent, and then dry , crushing, and sieving, and the modification of inorganic non-metallic nano-fillers is completed in this process. Afterwards, the modified inorganic non-metallic nano-filler was ground for 40 minutes with a high-...

Embodiment 2

[0041] The difference from Example 1 is that in the raw material formula of this example, nano-ZnO is used as the inorganic non-metallic nano-filler, PP-R resin is used as the plastic substrate, and other types of coupling agents and different proportions are selected.

[0042] In parts by mass, the raw material formula of inorganic nano antibacterial PP-R is as follows:

[0043]

[0044] (1) The preparation method and processing of inorganic nanometer antibacterial agent are as follows:

[0045] First, the inorganic non-metallic nanofillers were dispersed in a mixed solvent of trichlorethylene (Beijing Kexi Century Technology Co., Ltd.) and toluene (Jinbo Chemical Co., Ltd.) to form a slurry with a mass fraction of 15%. ℃ with magnetic stirring (model: DF-101S, Henan Qiuzuo Instrument Equipment Co., Ltd.) water bath heating, after stirring evenly, according to the above formula, add coupling agent, react at this temperature for 3 hours, and then put the slurry at 120 Heat...

Embodiment 3

[0049] The difference with Example 1 is: adopt nano-TiO in the raw material formula of this example 2 As an inorganic non-metallic nano filler, PP resin is used as a plastic substrate, and other types of coupling agents and different ratios are selected.

[0050] In parts by mass, the raw material formula of inorganic nano antibacterial PP is as follows:

[0051]

[0052] (1) The preparation method and processing of inorganic nanometer antibacterial agent are as follows:

[0053] First, disperse the inorganic non-metallic nano-filler into petroleum ether solvent (Shenghua Fine Chemical Group Co., Ltd.), make a slurry with a mass fraction of 20%, and use a magnetic stirring water bath at 80 °C (model: DF-101S, Henan Qiuzuo Instrument Equipment Co., Ltd.) heated, stirred evenly, added coupling agent according to the above formula, reacted at this temperature for 3 hours, then heated the slurry to reflux at 120°C, evaporated the solvent, and then dried, Crushing and sieving,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com