Method for preparing ZnO/Al film on solar cell without introduced electrode

A technology for solar cells and introduction of electrodes, applied in sustainable manufacturing/processing, circuits, electrical components, etc., to achieve the effects of excellent optoelectronic properties, improved conversion efficiency, and easy control of the deposition process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

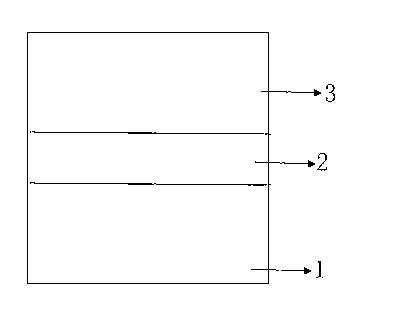

Image

Examples

Embodiment 1

[0024] Taking the solar cells without electrodes as the substrate, the substrate is ultrasonically cleaned with acetone, ethanol and deionized water in sequence, dried with nitrogen, and sent to the magnetron sputtering reaction chamber;

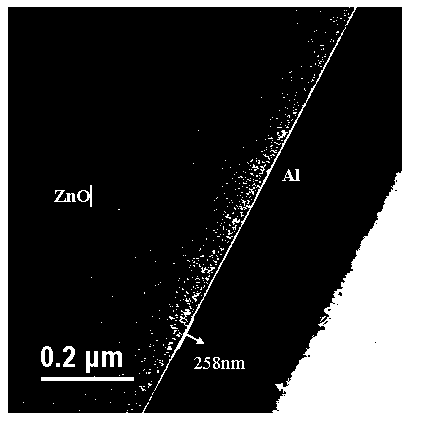

[0025] Vacuumize the magnetron sputtering reaction chamber to 9.0×10 -4 After Pa, the substrate is heated to 100°C, and the flow rate of argon gas is adjusted so that the pressure reaches 6Pa. Magnetron sputtering is performed with pure Al as the target material, the sputtering power is controlled at 100W, and the sputtering time is 4min, and a thickness of 258nm is obtained on the substrate. Al thin film;

[0026] Clean the above-mentioned substrate with Al film sputtered with deionized water, then place the substrate in a vapor deposition chamber and heat it to 200°C, and simultaneously feed oxygen and Zn(CH 2 CH 3 ) 2 Argon gas, wherein the ratio of argon and oxygen flow rate is 1: 100, control the microwave power to 650W, deposit a 5...

Embodiment 2

[0029] Taking the solar cells without electrodes as the substrate, the substrate is ultrasonically cleaned with acetone, ethanol and deionized water in sequence, dried with nitrogen, and sent to the magnetron sputtering reaction chamber;

[0030] Vacuumize the magnetron sputtering reaction chamber to 9.0×10 -4 After Pa, the substrate is heated to 100°C, and the flow rate of argon gas is adjusted so that the pressure reaches 6Pa. Magnetron sputtering is performed with pure Al as the target material. Al thin film;

[0031] Clean the above-mentioned substrate with Al film sputtered with deionized water, then place the substrate in a vapor deposition chamber and heat it to 200°C, and simultaneously introduce oxygen and Zn(CH 2 CH 3 ) 2 Argon gas, wherein the ratio of argon and oxygen flow rate is 1: 100, control the microwave power to 650W, deposit a 50nm thick ZnO film on the substrate with Al film, then clean the vapor deposition chamber with high-purity nitrogen gas, take o...

Embodiment 3

[0034] Taking the solar cells without electrodes as the substrate, the substrate is ultrasonically cleaned with acetone, ethanol and deionized water in sequence, dried with nitrogen, and sent to the magnetron sputtering reaction chamber;

[0035] Vacuumize the magnetron sputtering reaction chamber to 9.0×10 -4 After Pa, heat the substrate to 100°C, adjust the flow rate of argon gas to make the pressure reach 6Pa, use pure Al as the target material for magnetron sputtering, control the sputtering power to 150W, and sputtering time for 5min to obtain a thickness of 50nm on the substrate. Al thin film;

[0036] Clean the above-mentioned substrate with Al film sputtered with deionized water, then place the substrate in a vapor deposition chamber and heat it to 200°C, and simultaneously introduce oxygen and Zn(CH 2 CH 3 ) 2 argon, wherein the ratio of argon and oxygen flow is 1: 105, depositing a 100nm thick ZnO film on a substrate with an Al film, then cleaning the vapor depos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com