Method for preparing infrared radiation amorphous coating

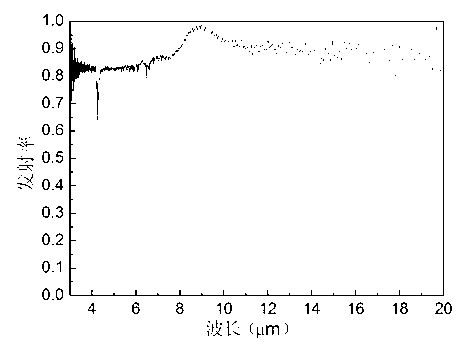

A technology of infrared radiation and amorphous coating, which is applied in the field of infrared radiation materials, can solve the problems of non-corresponding absorption peak wavelength, insignificant energy-saving effect, low emissivity, etc., and achieve long service life, excellent infrared radiation characteristics, and bonding strength high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A preparation method of an infrared radiation amorphous coating, the specific steps of the preparation method are:

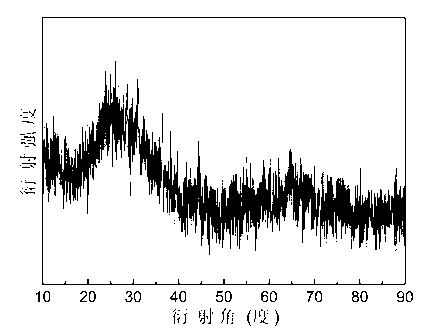

[0048] Step 1. Preparation of infrared radiation powder

[0049]5~10wt% iron oxide fine powder, 5~10wt% manganese oxide fine powder, 1~2wt% copper oxide fine powder, 1~2wt% cobalt oxide fine powder, 75~80wt% cordierite fine powder , 1-2wt% nickel oxide fine powder, 1-2wt% titanium oxide fine powder and 1-2wt% chromium oxide fine powder are uniformly mixed to prepare a mixture. Put the prepared mixture into a sagger, put the sagger into a microwave oven, heat it with radiation, raise the temperature to 1000~1050°C, keep it warm for 50~60min, cool, crush, and sieve to obtain 150~200 mesh Infrared radiation powder, spare.

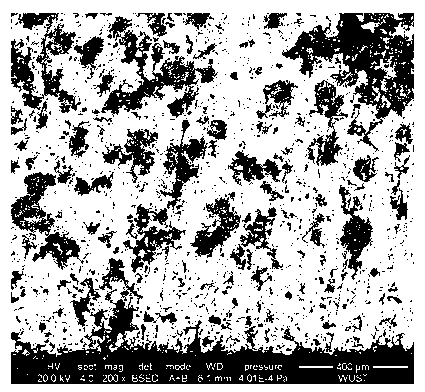

[0050] Step 2. Surface roughening of the metal substrate

[0051] The quartz sand is used as the raw material for sandblasting, and the surface of the metal substrate is sandblasted to obtain the metal substrate after the surface rough...

Embodiment 2

[0055] A preparation method of an infrared radiation amorphous coating, the specific steps of the preparation method are:

[0056] Step 1. Preparation of infrared radiation powder

[0057] 10~15wt% iron oxide fine powder, 10~15wt% manganese oxide fine powder, 2~3wt% copper oxide fine powder, 2~3wt% cobalt oxide fine powder, 60~70wt% cordierite fine powder , 2~3wt% nickel oxide fine powder, 2~3wt% titanium oxide fine powder and 2~3wt% chromium oxide fine powder are uniformly mixed to prepare a mixture. Put the prepared mixture into a sagger, put the sagger into a microwave oven, heat it with radiation, raise the temperature to 1050~1100°C, keep it warm for 40~50min, cool, crush, and sieve to obtain 200~250 mesh Infrared radiation powder, spare.

[0058] Step 2. Surface roughening of the metal substrate

[0059] Brown corundum sand is used as the raw material for sandblasting, and the surface of the metal substrate is sandblasted to obtain the metal substrate after the surfac...

Embodiment 3

[0063] A preparation method of an infrared radiation amorphous coating, the specific steps of the preparation method are:

[0064] Step 1. Preparation of infrared radiation powder

[0065] 15~20wt% iron oxide fine powder, 15~20wt% manganese oxide fine powder, 1~2wt% copper oxide fine powder, 1~2wt% cobalt oxide fine powder, 55~60wt% cordierite fine powder , 1-2wt% nickel oxide fine powder, 1-2wt% titanium oxide fine powder and 1-2wt% chromium oxide fine powder are uniformly mixed to prepare a mixture. Put the prepared mixture into a sagger, put the sagger into a microwave oven, heat it with radiation, raise the temperature to 1100~1150°C, keep it warm for 50~60min, cool, crush, and sieve to obtain 250~300 mesh Infrared radiation powder, spare.

[0066] Step 2. Surface roughening of the metal substrate

[0067] Carborundum is used as the raw material for sandblasting, and the surface of the metal substrate is sandblasted to obtain the metal substrate after surface roughening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com