Sulforaphane microencapsulation method

A technology of sulforaphane and microcapsules is applied in the field of microcapsule embedding of sulforaphane, which can solve the problems of being in the primary stage and the instability of sulforaphane, and achieve the effect of good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

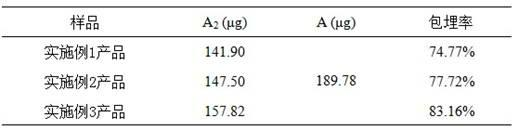

Examples

Embodiment 1

[0018] The first step, the extraction of sulforaphane: take 1500g of broccoli seeds and grind, add 100mL of petroleum ether to degrease, add 1500mL of phosphate buffer (pH 7.0) with a concentration of 35mol / mL, enzymatically hydrolyze, add 4000mL of dichloromethane Extract 3 times, add organic solvents (5g sodium sulfate and 15g sodium chloride) respectively, filter, concentrate in vacuo to remove organic solvents, dilute to 5000ml with methanol, filter with 0.22μm microfiltration membrane, determine sulforaphane by high performance liquid chromatography element content;

[0019] The second step, microencapsulation of sulforaphane: take 100 grams of gelatin, 800 grams of β-cyclodextrin, add 20 grams of sodium carboxymethyl cellulose as wall material, add 3 mL of monoglyceride, add 3 mL of sodium alginate, Add deionized water solution, after dissolving, add sulforaphane while stirring, homogenize three times, 10 minutes each time, set microencapsulation process parameters: inle...

Embodiment 2

[0021] The first step, the extraction of sulforaphane: Grind 1500g of kale seeds, add 100mL of petroleum ether to degrease, add 1500mL of 35mol / mL phosphate buffer solution (pH 7.0), enzymatically hydrolyze, add 4000mL of ethyl acetate to extract 3 times, add organic solvent (5g sodium sulfate and 15g sodium chloride), filter, vacuum concentrate to remove organic solvent, dilute to 5000mL with methanol, filter with 0.22μm microfiltration membrane, determine sulforaphane by high performance liquid chromatography content;

[0022] The second step, microencapsulation of sulforaphane: use whey protein and maltodextrin as wall materials, 200 grams of whey protein, 1400 grams of maltodextrin, add 3 mL of monoglyceride, add 3 mL of sodium alginate, add 100 mL of Deionized aqueous solution, after dissolving, add sulforaphane while stirring, homogenize twice, set microencapsulation process parameters for 12 minutes each time: inlet temperature 160°C, outlet temperature 70°C, spray dry,...

Embodiment 3

[0024] The first step, the extraction of sulforaphane: Grind 1500g of northern round carrot seeds, add 100mL of petroleum ether to degrease, add 1500mL of phosphate buffer (pH 7.0) with a concentration of 35mol / mL, enzymatically hydrolyze, add 4000mL of methanol Extract 3 times → add organic solvent (5g sodium sulfate and 15g sodium chloride), filter, concentrate in vacuo to remove organic solvent, use methanol to make up to 5000mL, filter with 0.22μm microfiltration membrane, determine sulforaphane by high performance liquid chromatography element content;

[0025] The second step, microencapsulation of sulforaphane: use calf serum and glutaraldehyde as wall materials, calf serum 300g, dissolve with 200mL deionized water, add glutaraldehyde 450ml, add monoglyceride 3mL, add Sodium alginate 3mL, add sulforaphane while stirring, homogenize three times, 8min each time, set microencapsulation process parameters: inlet temperature 150°C, outlet temperature 60°C, spray dry, collect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com