Cell microporous chip for detecting specific antibody secretion of single cell and preparation method thereof

A technology of cells and micropores, which is applied in the direction of measuring devices, biological testing, and analytical materials, etc., can solve the problems that the micropores cannot be single cells, the diameter of the micropores is large, and the requirements for instruments are very high, so as to achieve convenient preparation and operation. Simple, affordable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0128] Example 1: Design and manufacture of cell microwell chip template

[0129] The chip adopts the same semiconductor industry processing method as microfluidic technology, and the specific process is as follows:

[0130] (1) Make a circular array with equal diameter on the mask plate, and the array layout is 120×120. Use photolithography to transfer the pattern on the mask plate to a substrate such as a silicon wafer or glass that meets the flatness requirements. Photolithography technology is a semiconductor industrialization technology, including spin-coating (resist-spinning) photoresist, pre-baking, and ultraviolet exposure. , post-baking and developing steps, wherein the depth of the microhole of the present invention is determined by the thickness of the spin-coated photoresist during photolithography;

[0131] (2) The completed silicon wafer or glass is also called a mold, and the mold itself and the required chip are in a complementary structure, that is, a cylind...

Embodiment 2

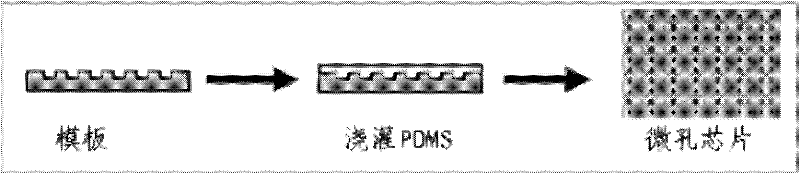

[0133] Example 2: PDMS cell chip fabrication and chip surface treatment

[0134] (1) PDMS (Polydimethylsiloxane) is a polymer material widely used in microfluidics and other fields; it is a biocompatible material, non-toxic, good gas permeability, and suitable for cell survival.

[0135] a) Hydrophobizing treatment is carried out on the surface of the prepared mold in order to make the PDMS easy to separate from the surface of the mold after curing. There are many ways of treatment, and the present invention adopts the method of spraying hydrophobic silane;

[0136] b) Take Silicone elastomer base: SYGARD 184 silicone elastomer curing agent = 10:1 (mass ratio) in a beaker and mix well;

[0137] c) Pour the PDMS glue onto the mold, and use a vacuum to drive away the air dissolved in PDMS during preparation;

[0138] d) Place it at room temperature until it is cured, or put the PDMS glue in an oven for baking, and take it out after it is completely cured. The way of baking can...

Embodiment 3

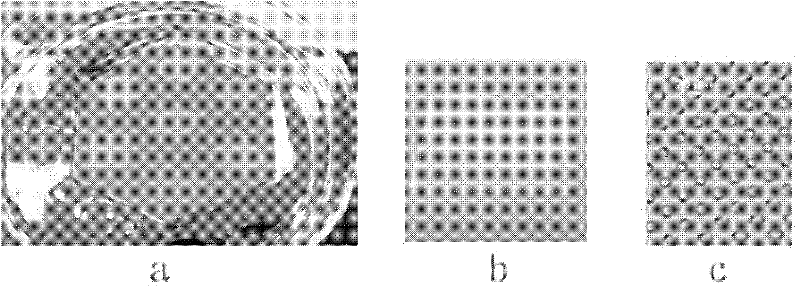

[0144] Embodiment 3: cell seeding density experiment

[0145] (1) Hybridoma cell line: dilute the concentration of hybridoma cells with RPMI1640 culture medium to make the concentration 1.0×10 6 pcs / ml, 2.0×10 6 pcs / ml, 4.0×10 6 pcs / ml, 6.0×10 6 pcs / ml, 8.0×10 6 pieces / ml. Inoculate PDMS chips whose surface has been treated to be hydrophilic, inoculate 100 μl of each chip, let it stand for 10 minutes, and then use RPMI1640 culture solution to wash the chip surface, observe under a microscope and make statistics.

[0146] (2) Mouse spleen cells: separate mouse spleen cells and adjust the density to 1.0×10 6 pcs / ml, 2.0×10 6 pcs / ml, 4.0×10 6 pcs / ml, 6.0×10 6 pcs / ml, 8.0×10 6 Each chip was inoculated with PDMS chips whose surface was treated to be hydrophilic, and each chip was inoculated with 100 μl, left to stand for 10 minutes, and then the surface of the chip was washed with RPMI1640 culture solution, observed under a microscope and counted.

[0147] Experiments hav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com