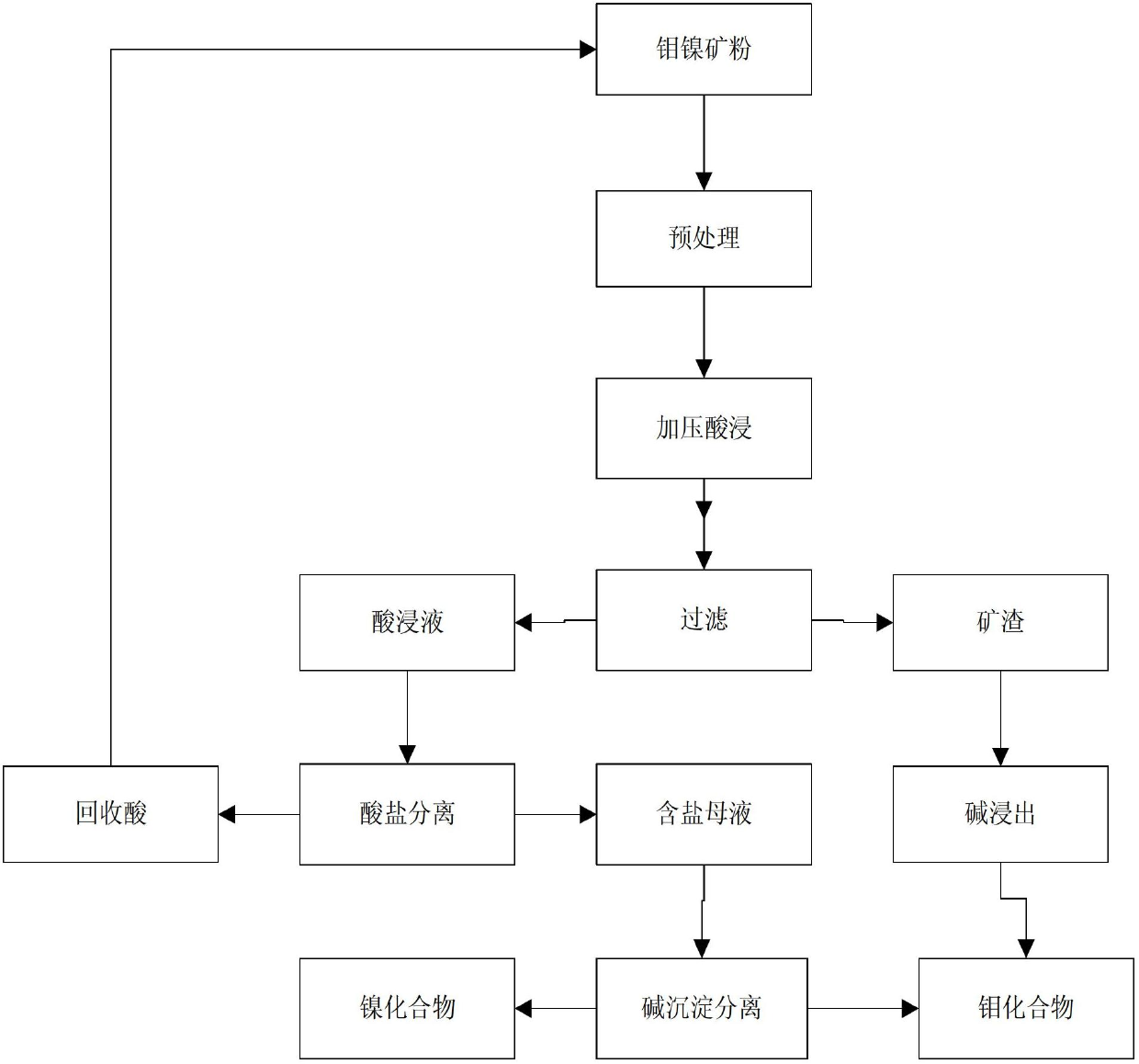

Resource utilization method for catalytic oxidation leaching of molybdenum and nickel from molybdenum-nickel ore

A technology for catalytic oxidation and molybdenum-nickel ore, which is applied in the direction of improving process efficiency to achieve the effects of easy control of the reaction, improved leaching effect and mild reaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

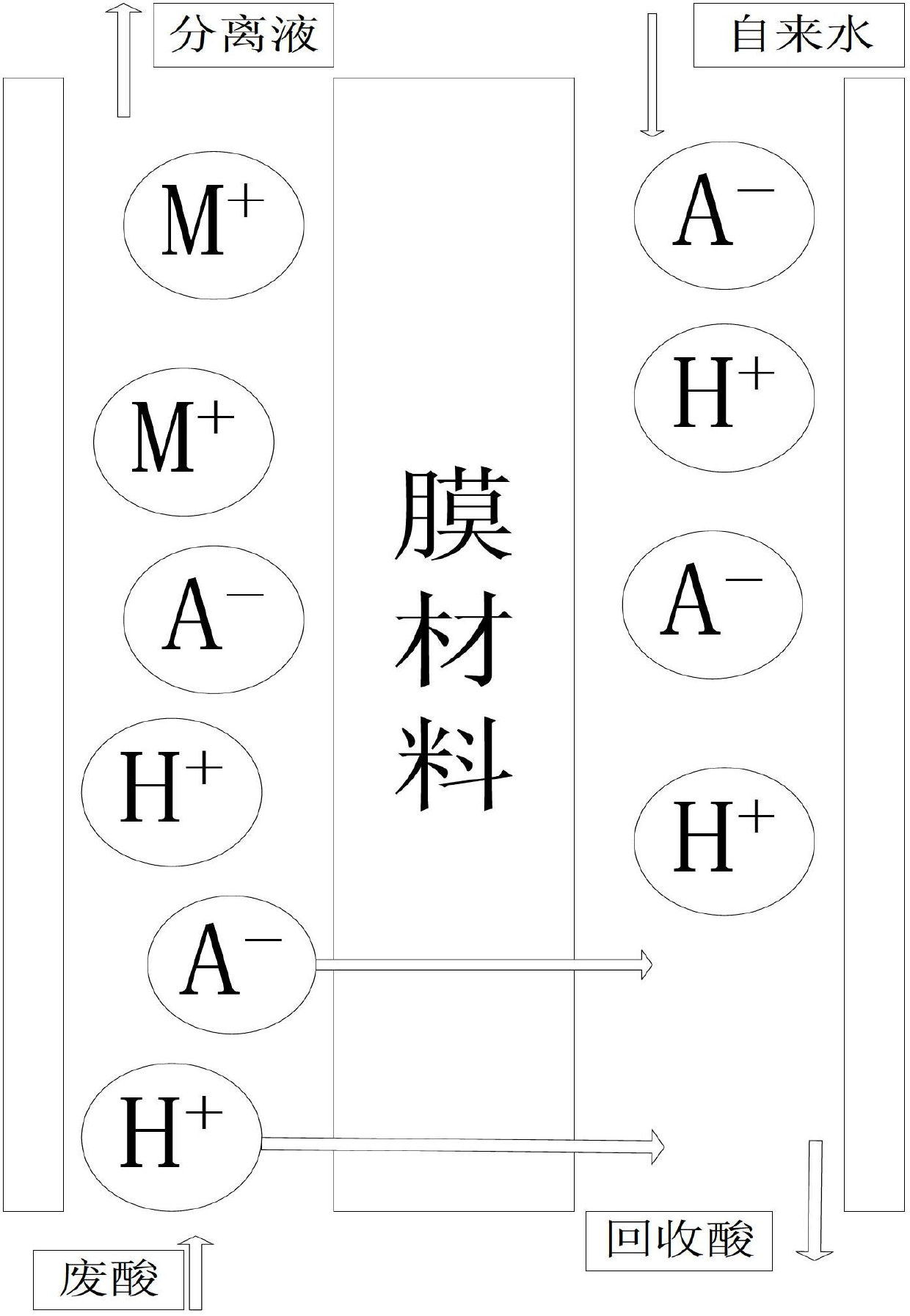

[0047] The molybdenum-nickel raw ore is crushed and ground to obtain a molybdenum-nickel ore powder with a particle size of 200-300 meshes. The active ingredients of the molybdenum-nickel ore: molybdenum is 6.1%, nickel is 3.2%, and sulfur is 23%. The mass percentage of 1000g is 98.3% sulfuric acid and 200g sodium nitrate were prepared into 5000ml aqueous solution, and the above-mentioned 2000g molybdenum-nickel ore powder and 5000ml solution were added to the reaction kettle, and 15g elemental iron powder was added to fully mix for oxidative leaching; after heating to 100°C, stop heating, because The reaction is an exothermic reaction, the temperature will naturally rise to 150°C, keep the reaction pressure at 0.7Mpa, the oxygen partial pressure at 0.35MPa, and react for 2.5 hours. After the reaction, the leachate with a total acid content of 260g / l was obtained by filtration, and the acid and salt were separated by membrane technology (selective diffusion dialysis membrane). ...

Embodiment 2

[0050] The molybdenum-nickel ore is crushed and ground to obtain molybdenum-nickel ore powder with a particle size of 200-300 meshes. The active ingredients of the molybdenum-nickel ore: molybdenum is 6.1%, nickel is 3.2%, and sulfur is 23%; the mass percentage of 900g is 98.3% % sulfuric acid and 200g sodium nitrate to prepare 5000ml aqueous solution, add the above-mentioned 2000g molybdenum-nickel ore powder and 5000ml solution into the reaction kettle, add 30g ferrous sulfate and mix thoroughly for oxidative leaching; stop heating after heating to 100°C, due to reaction It is an exothermic reaction, the temperature will naturally rise to 140°C, keep the reaction pressure at 0.6Mpa, oxygen partial pressure at 0.4MPa, and react for 3 hours. After the reaction, the total acid content in the leachate was filtered to be 250g / l. After the salt was separated by membrane technology (selective diffusion dialysis membrane), the total acidity of the separated liquid containing metal io...

Embodiment 3

[0053] The molybdenum-nickel ore is crushed and ground to obtain molybdenum-nickel ore powder with a particle size of 200-300 meshes. The active ingredients of the molybdenum-nickel ore: molybdenum is 6.1%, nickel is 3.2%, and sulfur is 23%; the mass percentage of 600g is 98% % sulfuric acid and 200g sodium nitrate to prepare 5000ml aqueous solution, add the above-mentioned 2000g molybdenum-nickel ore powder and 5000ml solution into the reaction kettle, add 36g copper sulfate and mix thoroughly for oxidative leaching; stop heating after heating to 120°C, because the reaction is Exothermic reaction, the temperature will naturally rise to 155°C, keep the reaction pressure at 0.8Mpa, oxygen partial pressure at 0.5MPa, and react for 2 hours. After the reaction was finished, the total acidity in the leachate obtained by filtration was 168g / l. After the salt was separated using membrane technology (selective membrane technology (selective diffusion dialysis membrane)), the total acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com