Color filter substrate and manufacturing method for same

A color filter and manufacturing method technology, applied in the direction of optical filters, optics, optical components, etc., can solve the problems of no optical difference, low production efficiency and production capacity, and reduce equipment utilization rate, so as to improve the position Calculate the accuracy and equipment utilization rate, improve production efficiency and throughput, and enhance the effect of optical difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. The following examples are only used to illustrate the present invention, but should not be used to limit the scope of the present invention.

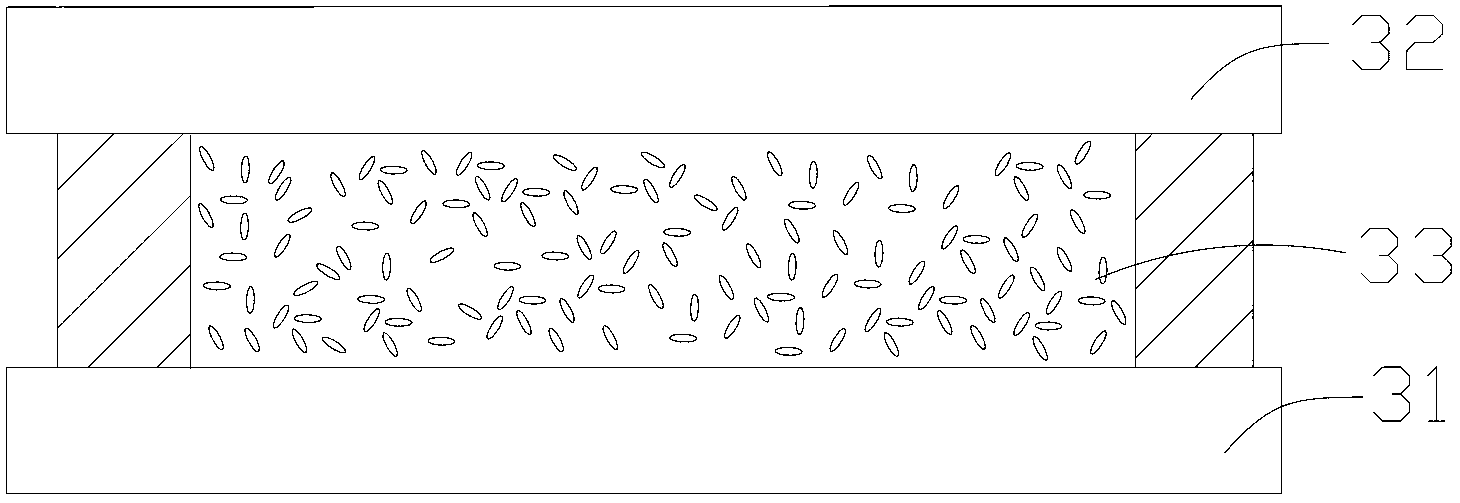

[0029] see image 3 , is a schematic structural view of a liquid crystal panel with a color filter substrate of the present invention. In this embodiment, the liquid crystal panel includes an active matrix substrate 31, a color filter substrate 32, and a substrate clamped between the active matrix substrate 31 and the color filter substrate. The liquid crystal layer 33 between the optical sheet substrates 32 .

[0030] The active matrix substrate 31 and the color filter substrate 32 are disposed opposite to each other, and include a transparent substrate, driving wiring and an alignment layer disposed on the transparent substrate. Since the active matrix substrate 31 used in the present invention is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com