Lithium iron phosphate material wrapped by fluorine-doped tin oxide and preparation method of lithium iron phosphate material

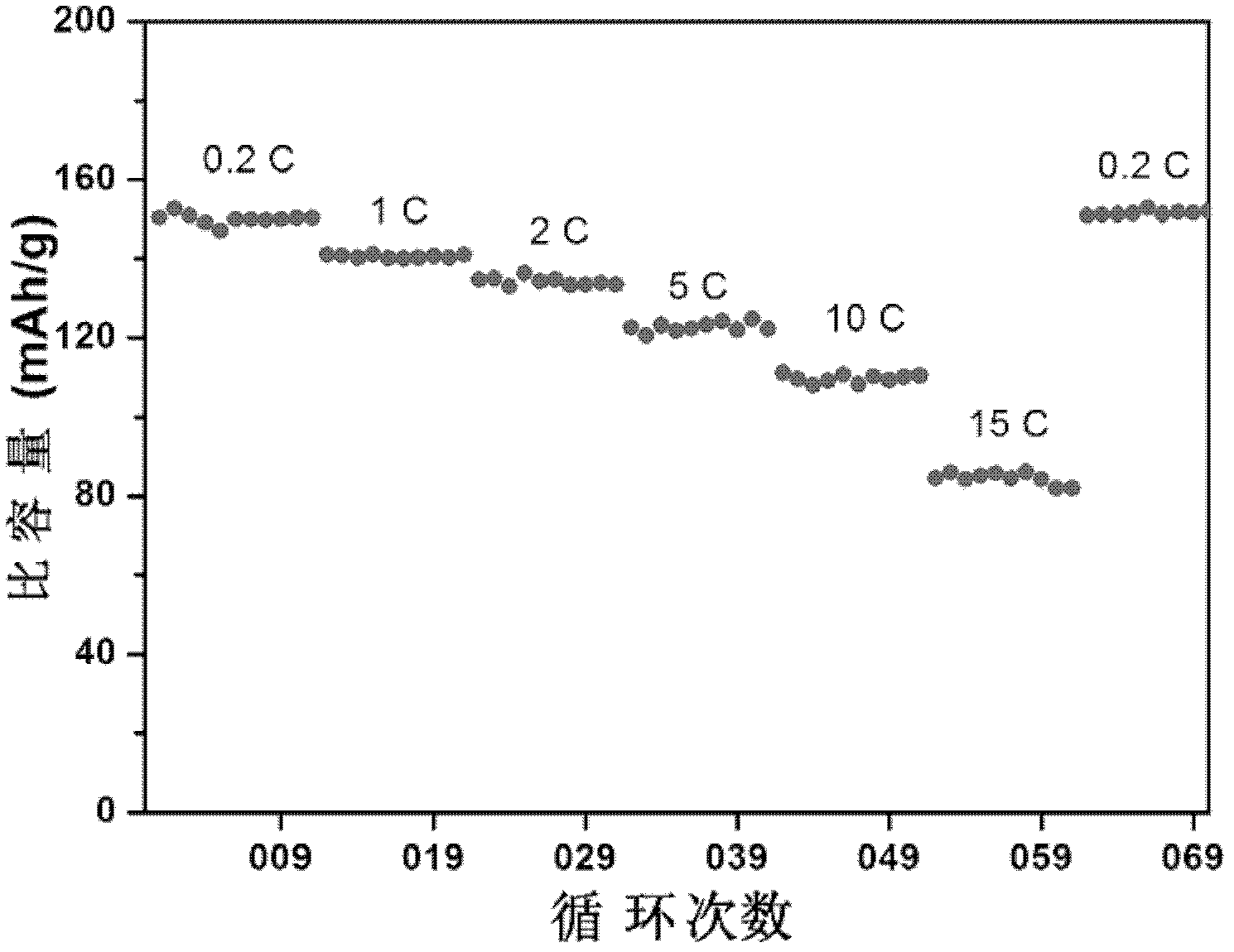

A fluorine-doped tin oxide and coating technology is applied in the field of positive electrode materials for lithium ion batteries, which can solve the problems of poor cycle rate performance and capacity density, low tap density, and poor conductivity of composite materials, and achieve improved cycle performance and Rate performance, low cost, and the effect of improving rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Weigh 0.019g ammonium fluoride (NH 4 F) and 0.609g tin tetrachloride pentahydrate (SnCl 4 ·5H 2 (2), be dissolved in 20mL acetone to form a solution; the solution obtained is fully mixed with 10g ferrous oxalate, 6.356g ammonium dihydrogen phosphate and 2.144g lithium carbonate, and dried to obtain a mixed material; the mixed material is heated in an argon atmosphere , react at 550° C. for 10 hours, and then cool with the furnace to obtain a reaction product; grind the reaction product to obtain a fluorine-doped tin oxide (FTO) / lithium iron phosphate composite material for a positive electrode of a lithium ion battery.

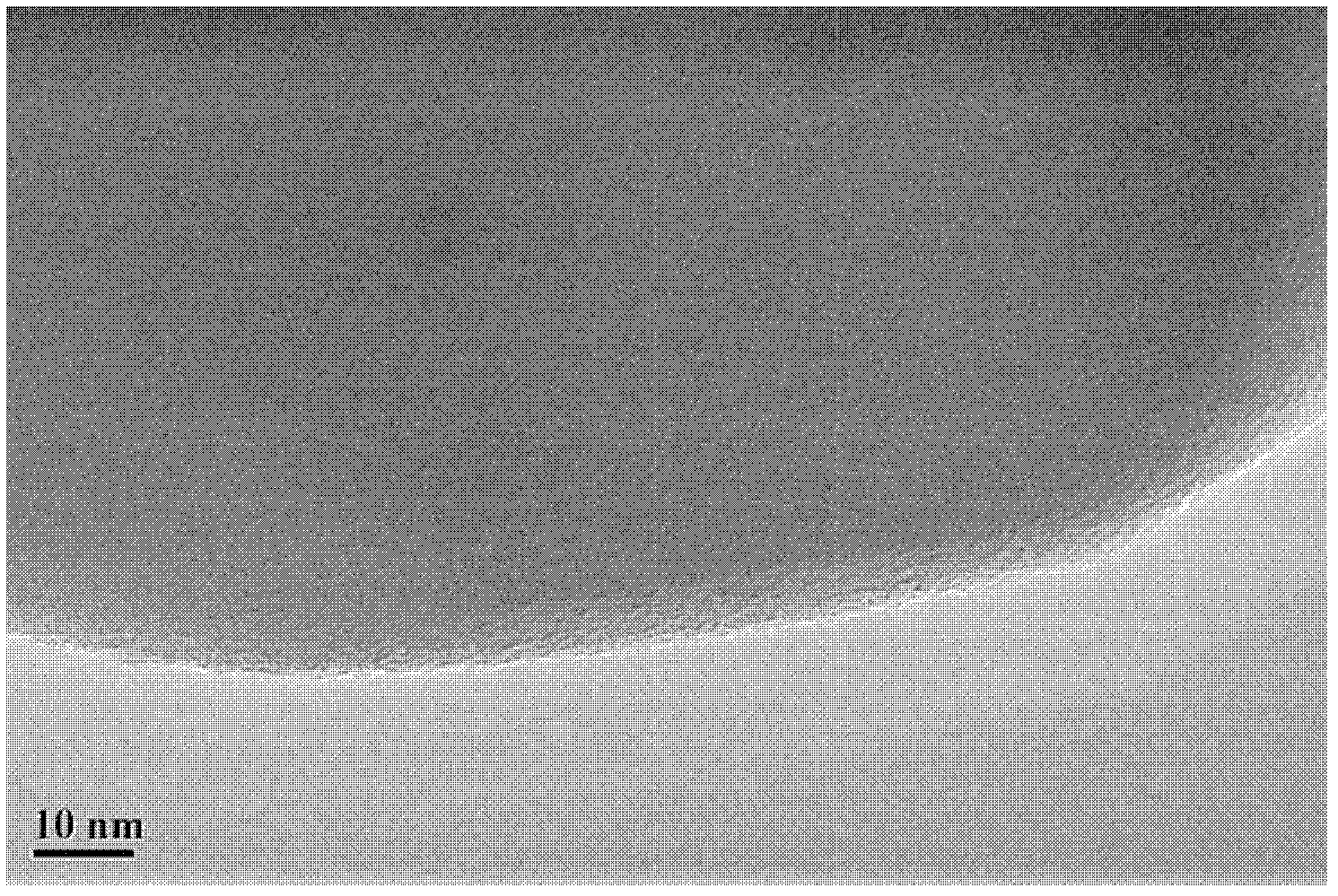

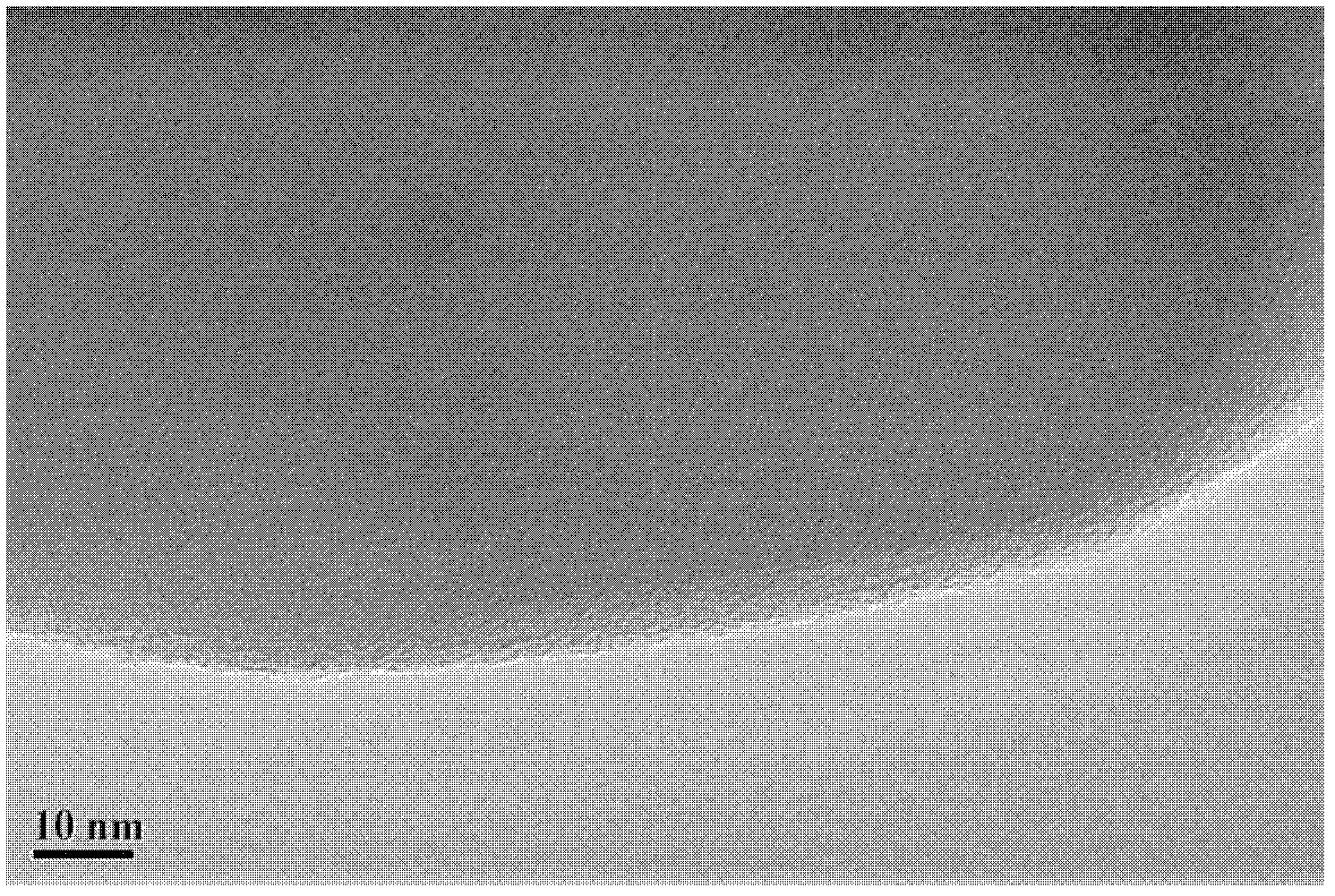

[0024] The fluorine-doped tin oxide (FTO) / lithium iron phosphate composite material obtained for the positive electrode of lithium-ion batteries was observed by transmission electron microscopy, and the results were as follows: figure 1 shown. From figure 1 It can be seen that the thickness of the FTO coating layer in the obtained FTO-coated lithium...

Embodiment 2

[0027] Weigh 0.021g hydrofluoric acid (HF) and 0.715g tin oxychloride (SnOCl 2 ), dissolved in 25mL ethanol to form a solution; the obtained solution was fully mixed with 8.877g ferrous oxalate, 14.595g ammonium dihydrogen phosphate and 2.752g lithium hydroxide, and dried to obtain a mixed material; atmosphere, react at 600°C for 9 hours, and then cool with the furnace to obtain the reaction product; grind the reaction product to obtain the fluorine-doped tin oxide (FTO) / lithium iron phosphate composite material for the positive electrode of lithium-ion batteries.

Embodiment 3

[0029] Weigh 0.059g ammonium fluoride (NH 4 F) and 1.835g tin tetrachloride pentahydrate (SnCl 4 ·5H 2 O), be dissolved in 50mL acetone, form a solution; The solution obtained is mixed with 38.84g ferric oxalate, 16.247g phosphoric acid and 17.619g lithium acetate dihydrate (CH 3 COOLi·2H 2 O) fully mixed and dried to obtain the mixed material; the mixed material was reacted in a nitrogen atmosphere at 550°C for 7 hours, and then cooled with the furnace to obtain a reaction product; the reaction product was ground to obtain a lithium-ion battery positive electrode with fluorine-doped oxidation Tin (FTO) / lithium iron phosphate composite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com