Titanium material capacitance battery

A capacitor battery, titanium powder technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of large self-discharge, small electric capacity, and low internal pressure of super capacitor batteries, and achieve high current charge and discharge. The effect of strong capacity, high charge and discharge current density, and high energy conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

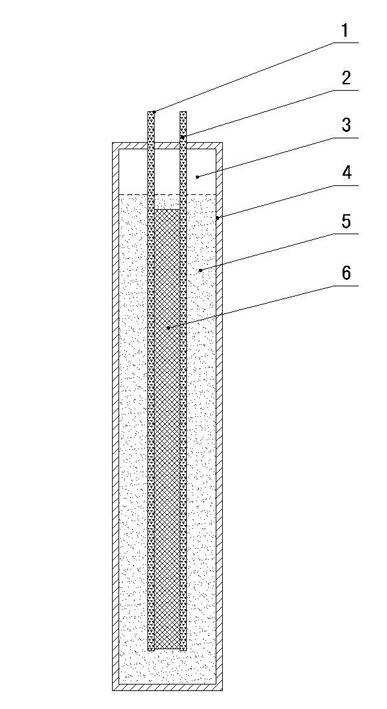

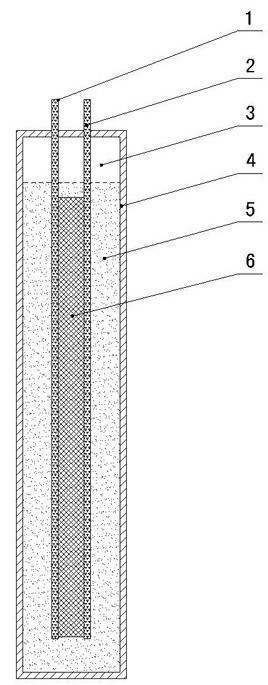

[0031] Taking the single-cell two-piece pole plate as an example, titanium powder is used to process titanium microporous plate with gas permeability, or titanium powder is sintered to process titanium suboxide microporous plate, or it is made of titanium mesh or titanium foil plate or surface Titanium-nickel-plated plates made of 150×150×0.8—1.2 positive and negative plates are put into the shell, and sponge bodies are arranged between the positive and negative plates. Negative electrode lead-out wire, inject high-energy and high-permittivity polymer electrolyte into the shell, the polymer electrolyte can be lead tetrafluoroborate solution with 1.0% C16H33(CH3)N+ added as an additive, and the content of divalent lead is 20% %, the content of free boric acid is 1.5%, and the content of free boric acid is 1.0%; the polymer electrolyte 5 contains 0.02% iron and 0.01% lead sulfate.

[0032] The polymer electrolyte can also be a mixture of lead methanesulfonate and methanesulfonic...

Embodiment 2

[0035] Taking the single-cell two-piece pole plate as an example, titanium powder is used to process titanium microporous plate with gas permeability, or titanium powder is sintered to process titanium suboxide microporous plate, or it is made of titanium mesh or titanium foil plate or surface Titanium-nickel-plated plates made of 150×150×0.8—1.2 positive and negative plates are put into the shell, and sponge bodies are arranged between the positive and negative plates. Negative electrode lead wire, inject high energy and high dielectric constant polymer electrolyte into the shell, the polymer electrolyte can be lead tetrafluoroborate solution with 1.5% C16H33(CH3)N+ added as an additive, and the content of divalent lead is 25% %, free boric acid content 2%, free fluoboric acid content 1.2%; the polymer electrolyte 5 contains 0.03% iron and 0.018% lead sulfate.

[0036] Leave enough space, seal and evacuate, charge and polarize with constant voltage and constant current, singl...

Embodiment 3

[0038] Taking the single-cell two-piece pole plate as an example, titanium powder is used to process titanium microporous plate with gas permeability, or titanium powder is sintered to process titanium suboxide microporous plate, or it is made of titanium mesh or titanium foil plate or surface Titanium-nickel-plated plates made of 150×150×0.8—1.2 positive and negative plates are put into the shell, and sponge bodies are arranged between the positive and negative plates. Negative electrode lead wire, inject high-energy and high dielectric constant polymer electrolyte into the shell, the polymer electrolyte can be lead tetrafluoroborate solution with 2.0% C16H33(CH3)N+ added as an additive, and the content of divalent lead is 28 %, 2.5% free boric acid content, 1.2% free fluoboric acid content; the polymer electrolyte 5 contains 0.04% iron and 0.02% lead sulfate.

[0039] Leave enough space, seal and evacuate, charge and polarize with constant voltage and constant current, singl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com