Solid-acid-catalyzed method for synthesizing straight-chain alkyl-benzene

A technology of straight-chain alkylbenzene and solid acid catalysts, applied in chemical instruments and methods, molecular sieve catalysts, physical/chemical process catalysts, etc., can solve the problems of short single-pass life, easy deactivation, etc., and achieve good activity stability, Reduced energy consumption and high olefin conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

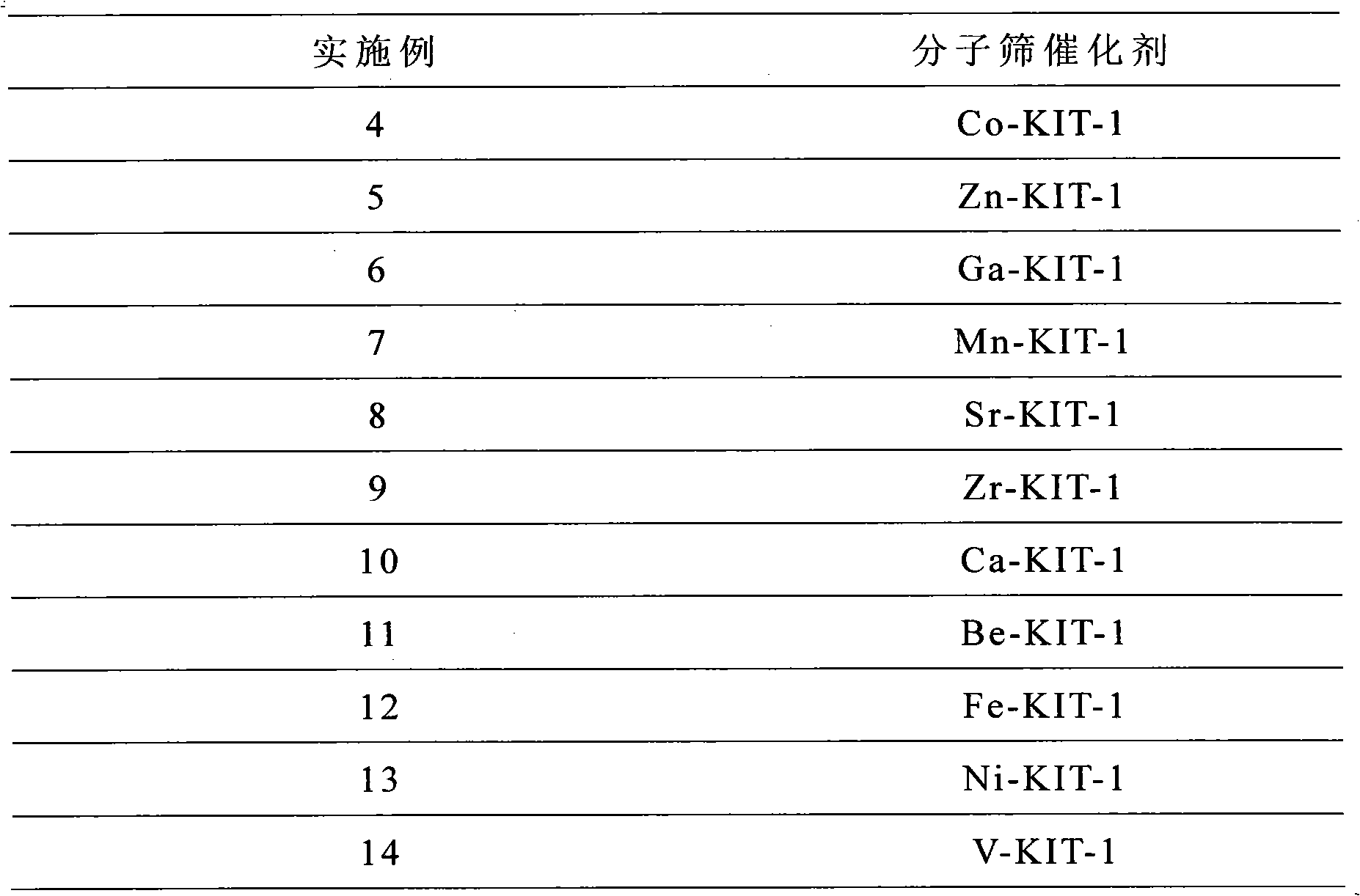

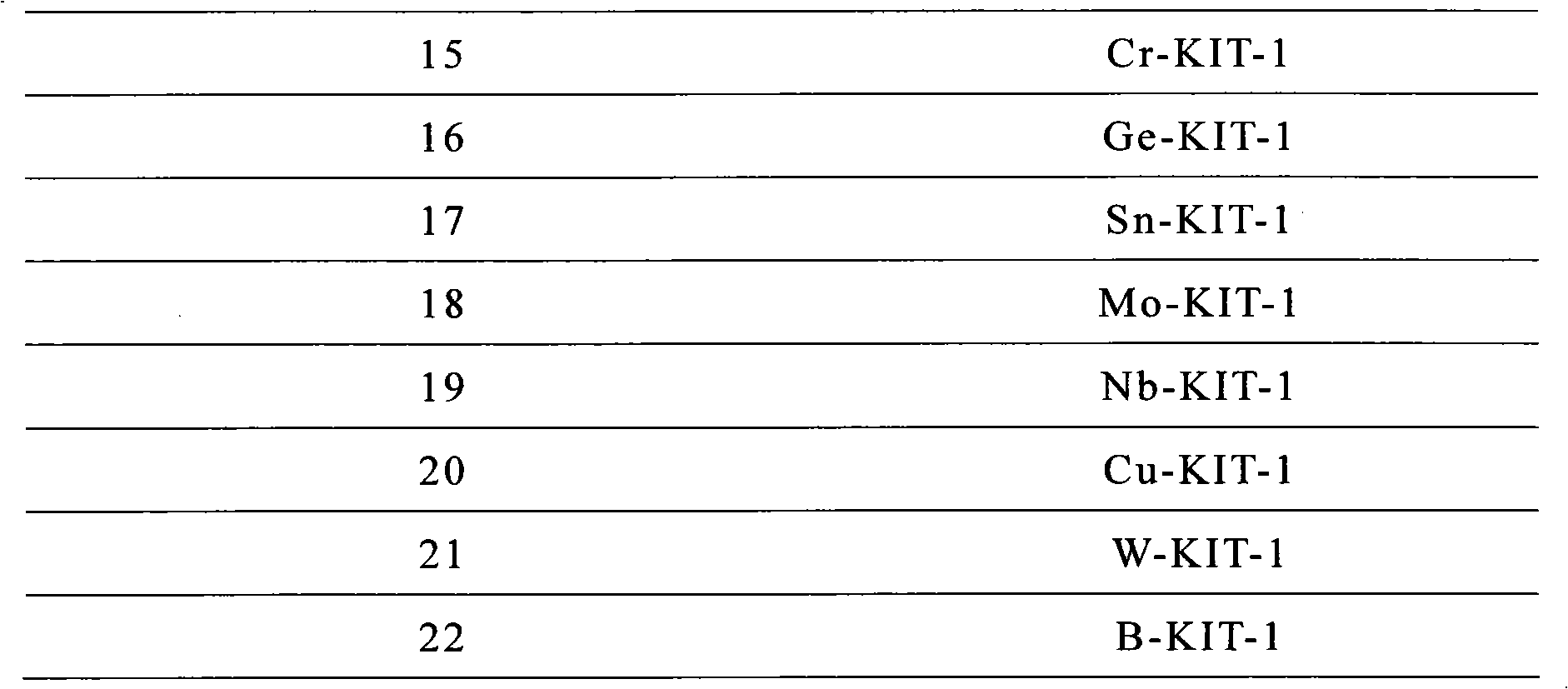

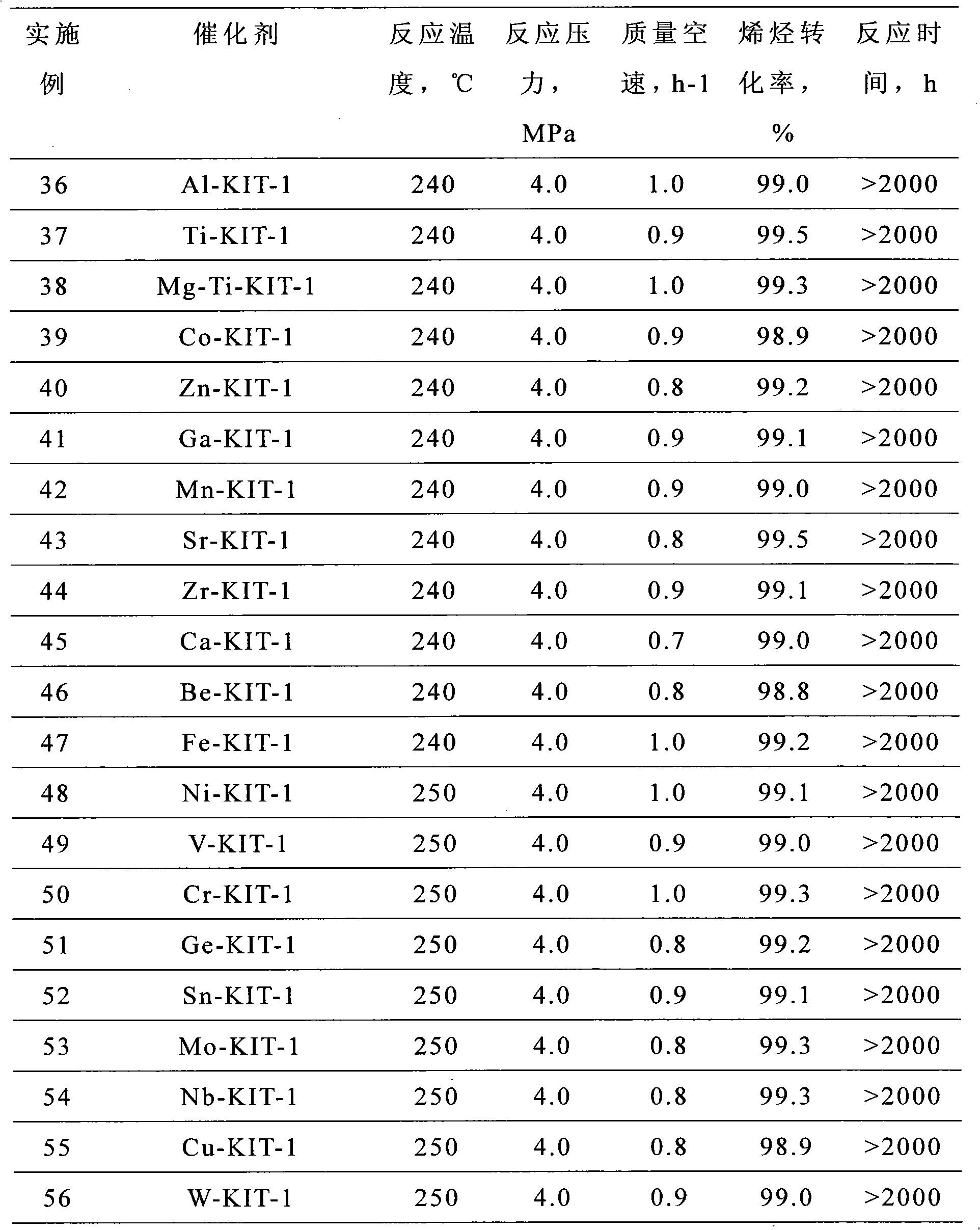

Examples

Embodiment 1

[0028] Embodiment 1: the synthesis of Al-KIT-1 type molecular sieve catalyst

[0029]Sodium silicate, cetyltrimethylammonium bromide, disodium edetate, distilled water, sodium hydroxide, and aluminum oxide monohydrate were mixed in a ratio of 1:0.25:1:60:0.15:0.2 (amount of substance ratio) to mix, stir evenly, put into the reaction kettle, keep the temperature at 100°C for 24h; use 2mol / L H2SO4 solution to adjust the pH=10.5, then heat at 100°C for 24h, adjust the pH=10.5, and then reheat After 24 hours, the product was taken out, washed repeatedly with distilled water until pH = 7, air-dried, calcined at 540°C in a nitrogen atmosphere for 1 h, and then calcined in air for 6 h to obtain Na-Al-KIT-1 powder. Pickle the Na-Al-KIT-1 powder with 0.1mol / L HNO3, control the solid-liquid mass ratio to 1:10, stir at room temperature for 0.5h, filter, wash repeatedly with distilled water until pH = 7, and then ℃ drying, extrusion molding, to obtain Al-KIT-1 molecular sieve catalyst. ...

Embodiment 2

[0030] Embodiment 2: the synthesis of Ti-KIT-1 type molecular sieve catalyst

[0031] Mix sodium silicate, cetyltrimethylammonium bromide, disodium edetate, distilled water, and sodium hydroxide in a ratio of 4:1:4:240:0.6 (mass ratio of substances), and stir After uniformity, put it into the reaction kettle, keep the temperature at 100°C for 24h; use 2mol / L H2SO4 solution to adjust the pH=10.5, keep the temperature at 100°C for 24h; adjust the pH=10.5 again, keep the temperature at 100°C for 24h; take out the product and repeat it with distilled water Wash until pH = 7, dry, and bake in air at 550°C for 6 hours to obtain Na-KIT-1 powder. Pickle the Na-KIT-1 powder with 0.1mol / L HNO3, control the solid-liquid mass ratio to 1:10, stir at room temperature for 0.5h, filter, wash repeatedly with distilled water until pH = 7, and then bake at 100°C Dry to obtain matrix KIT-1 molecular sieve. The matrix KIT-1 molecular sieve, butyl titanate and ethanol were stirred and mixed with ...

Embodiment 3

[0032] Embodiment 3: the synthesis of Mg-Ti-KIT-1 type molecular sieve catalyst

[0033] Mix sodium silicate, cetyltrimethylammonium bromide, disodium edetate, distilled water, and sodium hydroxide in a ratio of 4:1:4:240:0.6 (mass ratio of substances), and stir After uniformity, put it into the reaction kettle, keep the temperature at 100°C for 24h; use 2mol / L H2SO4 solution to adjust the pH=10.5, keep the temperature at 100°C for 24h; adjust the pH=10.5 again, keep the temperature at 100°C for 24h; take out the product and repeat it with distilled water Wash until pH = 7, dry, and bake in air at 550°C for 6 hours to obtain Na-KIT-1 powder. Exchange the Na-KIT-1 powder with 1.0mol / L ammonium nitrate aqueous solution, control the solid-liquid mass ratio to 1:10, stir and exchange at 90°C for 5.0h, filter, wash repeatedly with distilled water until pH=7, and then Dry at 100°C and calcined at 400°C for 3 hours to obtain the matrix KIT-1 molecular sieve. The matrix KIT-1 molecu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com