Treatment method for recycle of oil field produced water

A treatment method and technology for produced water, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, osmosis/dialysis water/sewage treatment, etc., can solve the problems of poor water quality and low treatment efficiency, and achieve Strengthen the flushing effect, reduce membrane fouling, and reduce the effect of membrane fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

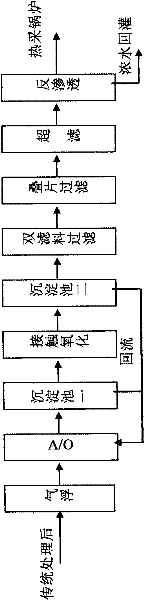

Image

Examples

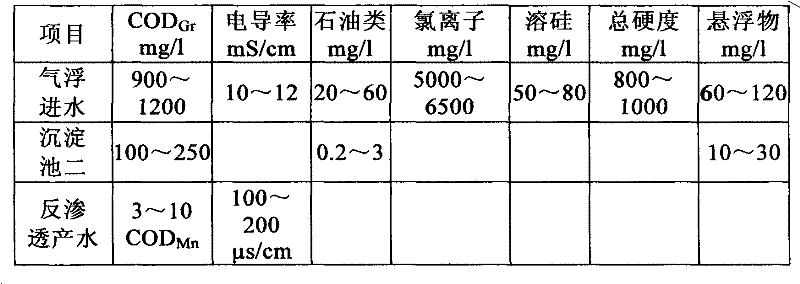

Embodiment 1

[0038] same steps figure 1 , the process parameters are as follows:

[0039] In step (2), the obligate combination strain was purchased from Beijing Tianhao Kerun Environmental Technology Co., Ltd. (Room 2601, Building B2, Tianchuang Shiyuan, No. 312 Huizhong Beili, Chaoyang District, Beijing, Tel: 010-84274689, Zip Code: 100012) The engineering bacteria preparation (composed of Desulfovibrio, Enterobacter, Clostridium, Desulfotomaculum, Pantoea bacteria, etc., by equal weight Proportional mixing, solid powder), use oilfield produced water to prepare sewage with COD not less than 200mg / L, and activate it by exposure for 4-5 days. The wet weight ratio is 3:7 for compounding. After compounding, the activated sludge is put into the hydrolytic acidification tank and the aerobic tank. The hydrolytic acidification will break the chain of oligomers and increase its BOD / COD ratio, and then enter the aerobic tank for preliminary removal. Some petroleum and organic matter in sewage. ...

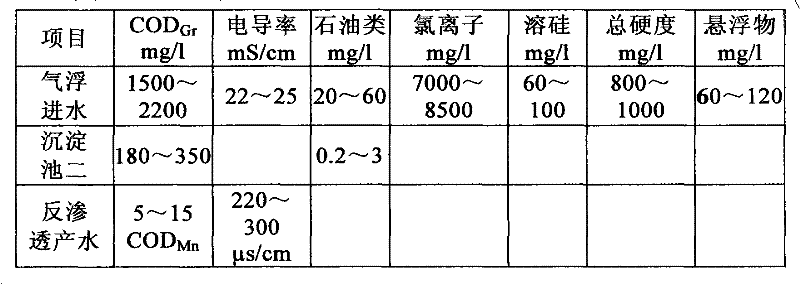

Embodiment 2

[0049] same steps figure 1 , the process parameters are as follows:

[0050] In step (2), the obligate combined bacteria is the same as in Example 1; the influent for hydrolysis and acidification is 3m 3 / h, the hydraulic retention time is 12h, the hydraulic retention time of the aerobic tank is 15h, and the design air-water ratio is 25:1;

[0051] In step (3) and step (5), the rising velocity of the settling tank is 1.2m / h;

[0052] In step (4), the hydraulic retention time of the contact oxidation tank is 17h;

[0053] In step (6), the filtration rate of the double filter material filter is 8m / h;

[0054] In step (8), the ultrafiltration membrane flux is 30L / m 2 h; the forced circulation ratio (circulation volume: water intake) is 1.8:1; the cross-flow ratio (cross flow: water intake) is 0.1:1, backwashing with ultra-filtered water every 50 minutes, and normal backwashing 2 times the amount of water. Carry out a small chemical alkali wash every 8th backwash, the agents...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com