Preparation process for aluminosilicophosphate molecular sieve

A technology of aluminosilicate and molecular sieve, which is applied in the direction of molecular sieve characteristic silicoaluminophosphate, molecular sieve and alkali-exchanged phosphate, etc., can solve the problems of SAPO molecular sieve performance regulation and the understanding of natural layered aluminosilicate still needs to be improved And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

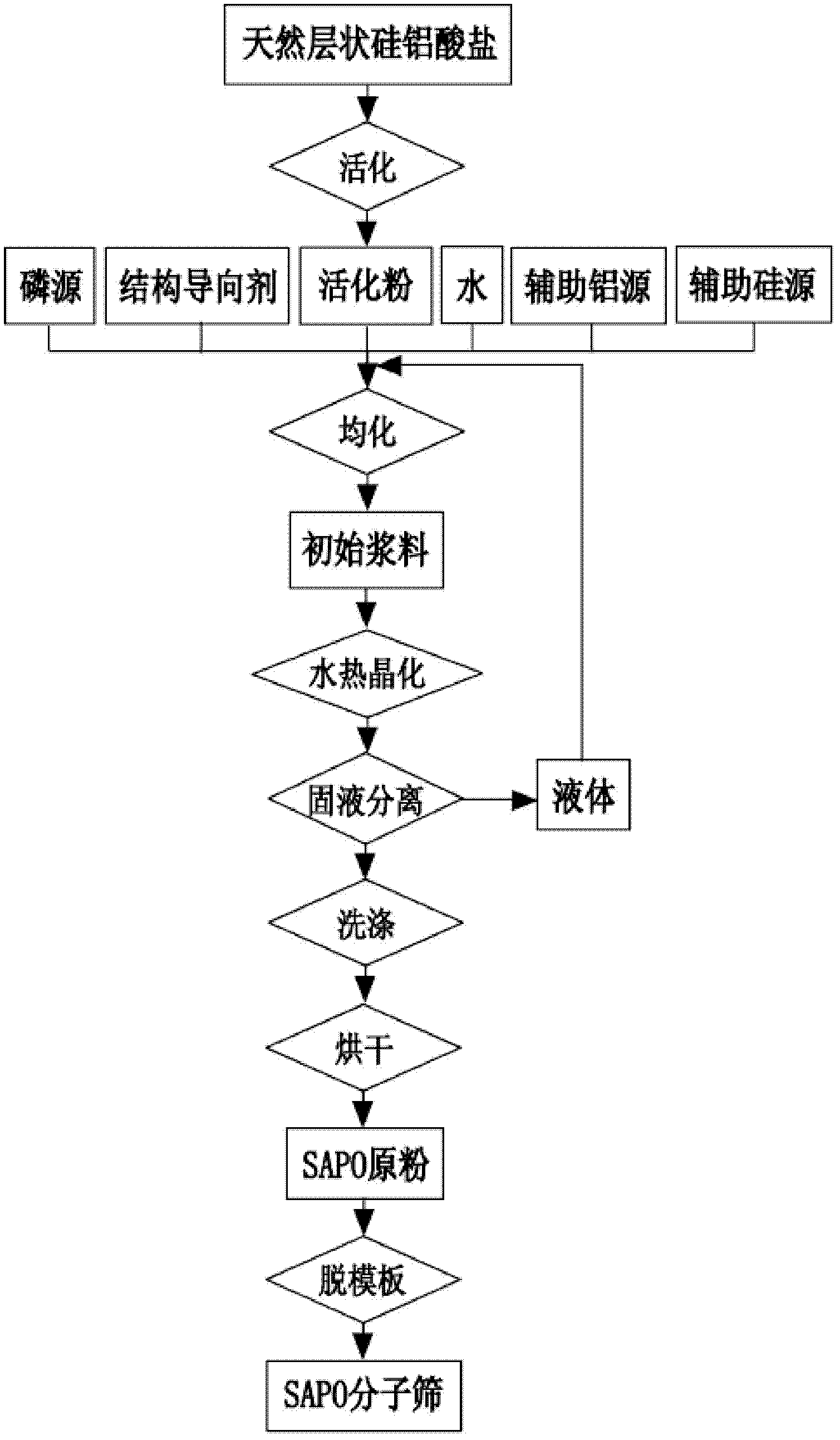

Method used

Image

Examples

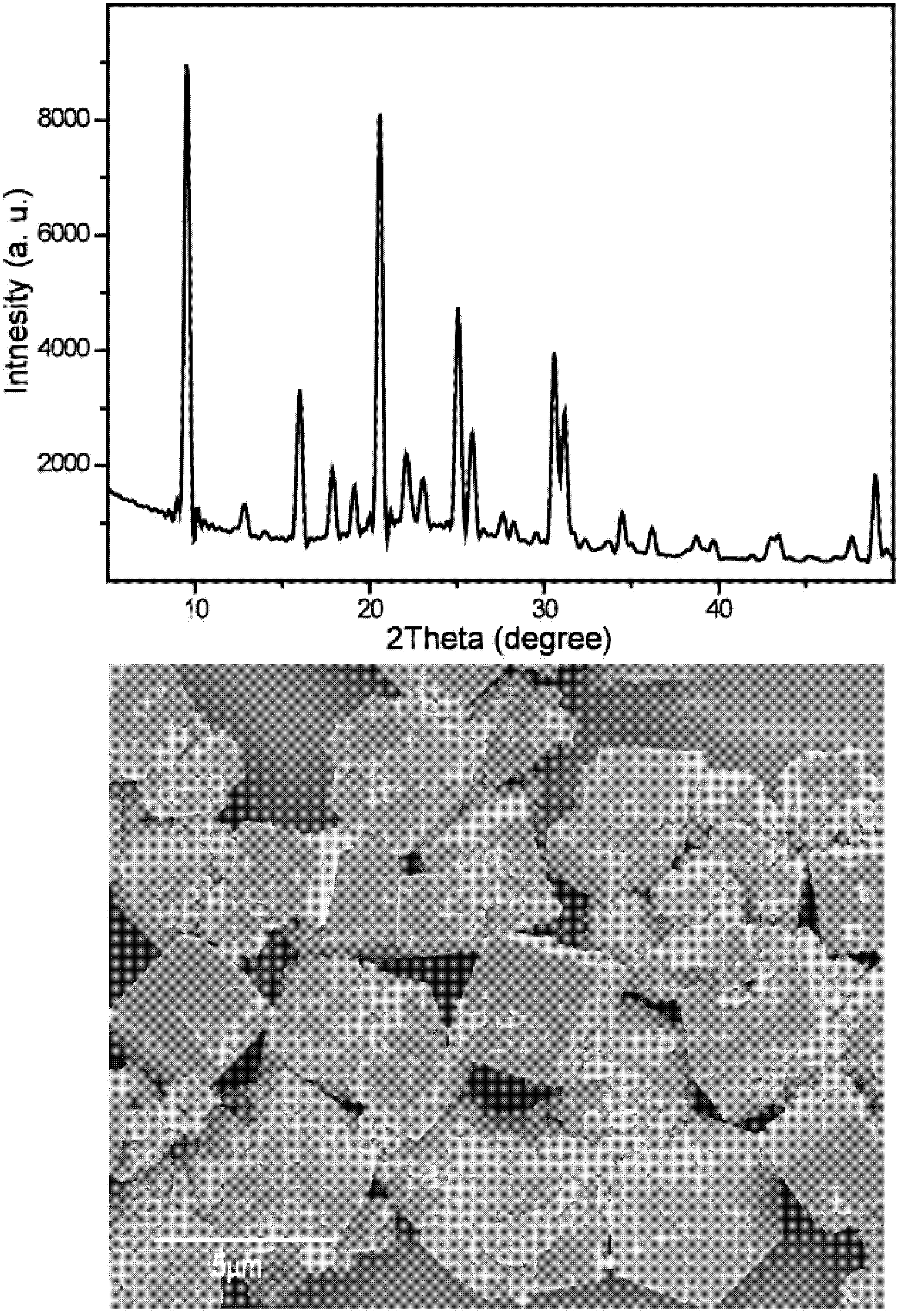

Embodiment 1

[0058] Inner Mongolia Hohhot coal series kaolin, kaolinite content is 92.5%.

[0059] Grind to an average particle size of less than 10 μm to obtain a ground activated powder.

[0060] Get 30.0g of grinding activation powder body, join in 200.0g deionized water, add pseudo-boehmite 16.4g (aluminum oxide content 78.0%) respectively afterwards, add 85.0% concentrated phosphoric acid 52.0g, morpholine 60.0g, get Mix slurry.

[0061] Transfer the above slurry to a 500ml resin ball mill jar, add 200g of zirconia balls with a diameter of 3mm, and mill for 8 hours in a planetary ball mill at a speed of 400r / min to obtain the initial slurry.

[0062] The above initial slurry was aged at room temperature for 24 h.

[0063] After aging, the initial slurry was transferred to a 500ml reactor lined with polytetrafluoroethylene, and crystallized at 240°C for 60h.

[0064] Suction filter the slurry after the crystallization reaction, and recover the filtrate for use. The solid filter res...

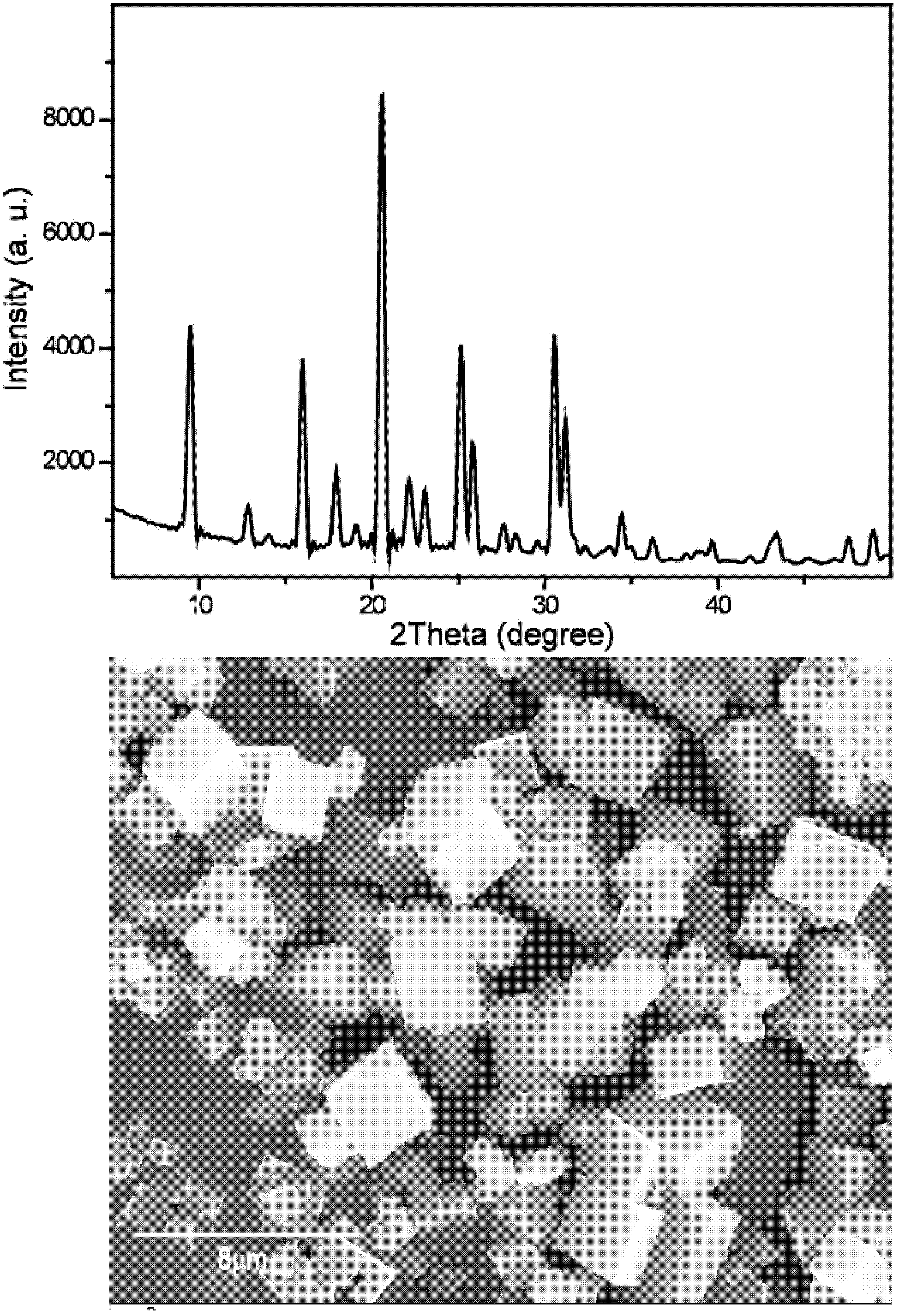

Embodiment 2

[0068] Coal-measure kaolin in Hohhot, Inner Mongolia, with a kaolinite content of 92.5%.

[0069] Grind to an average particle size of less than 50 μm, place it in a muffle furnace, and roast at 800°C for 2 hours to obtain a crushed and roasted activated powder.

[0070] Take 25.4 g of ground activated powder and add it to 200.0 g of deionized water, then add 13.0 g of activated alumina, 52.0 g of 85.0% concentrated phosphoric acid, and 60.0 g of morpholine to obtain a mixed slurry.

[0071] Transfer the above slurry to a 500ml resin ball mill jar, add 200g of zirconia balls with a diameter of 3mm, and mill in a planetary ball mill for 2 hours at a speed of 600r / min to obtain the initial slurry.

[0072] The above initial slurry was aged at room temperature for 24 h.

[0073] After aging, the initial slurry was transferred to a 500ml reactor lined with polytetrafluoroethylene, and crystallized at 200°C for 20h.

[0074] Suction filter the slurry after the crystallization rea...

Embodiment 3

[0078] Suzhou natural kaolin, kaolinite content is 90.6%.

[0079] Grind by wet ball milling until the average particle size is less than 50 μm, place it in a muffle furnace, and roast at 800°C for 2 hours to obtain crushed roasted activated powder.

[0080] Take 50.0 g of ground activated powder and place it in 300.0 g of deionized water, add 30.0 g of pseudoboehmite (78.0% alumina content), 100.0 g of 85.0% concentrated phosphoric acid, and 120.0 g of morpholine to obtain a mixed slurry material.

[0081] Transfer the above slurry to two 500ml resin ball milling tanks, add 200g of zirconia balls with a diameter of 3mm to the tanks respectively, and mill in a planetary ball mill for 20 hours at a speed of 400r / min to obtain the initial slurry.

[0082] The initial slurry was transferred to a PTFE-lined 1L reactor and crystallized at 200°C for 20h.

[0083] Suction filter the slurry after the crystallization reaction, and recover the filtrate for use. The solid filter resid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com