Multilayered film used for solar energy cell, preparation method thereof and purpose thereof

A technology of solar cells and multi-layer thin films, which can be applied to circuits, photovoltaic power generation, electrical components, etc., can solve the problem of high battery cost, and achieve the effect of reducing production cost and increasing photoelectric conversion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

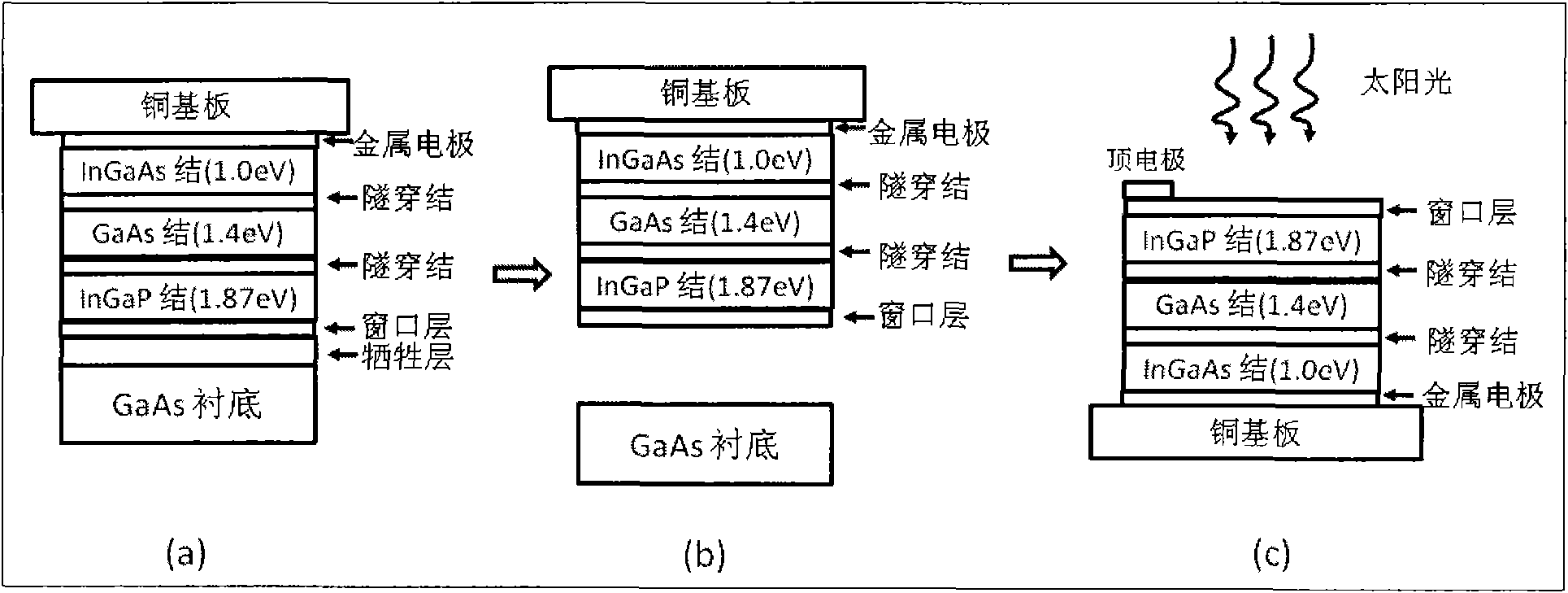

[0049] Example 1 III-V triple-junction tandem battery based on metal substrate provided by the present invention and preparation method thereof

[0050] This embodiment is a III-V triple-junction series battery based on a metal substrate provided by the present invention, and its complete structure is as follows Figure 4 shown, where:

[0051] 1 is an inexpensive amorphous substrate, which can be a copper substrate or an aluminum substrate, and is also used as one of the electrodes for current output.

[0052] 2 is a metal buffer lamination layer, mainly titanium-molybdenum-copper alloy, with a thickness of about 2 microns.

[0053] 3 is a high-concentration p-type doped gallium indium arsenide conductive layer with a thickness of 200 nanometers and a p-type doping concentration of 5×10 18 cm -3 .

[0054] 4 is the p-type gallium indium arsenide absorber layer, and the molar composition is In 0.3 Ga 0.7 As 1 , its lattice constant is 0.5775 nanometers, the correspond...

Embodiment 2

[0078] Example 2 III-V double junction tandem battery based on metal substrate provided by the present invention

[0079] This embodiment is a III-V group double-junction series battery provided by the present invention. remove Figure 4 Layers 4, 5, 6, and 7 in the structure constitute a double-junction P-N junction tandem battery based on gallium indium phosphide (InGaP) and gallium arsenide (GaAs), and its specific preparation process is the same as that of embodiment 1.

[0080] It has been determined that the conversion efficiency of the III-V family double-junction tandem battery is above 25%.

Embodiment 3

[0081] Example 3 Application of multi-junction thin-film solar cells based on amorphous lining provided by the present invention

[0082] This embodiment is an application of the high-efficiency multi-junction thin-film solar cell on an amorphous substrate of the present invention.

[0083] The application of the amorphous substrate high-efficiency multi-junction thin-film solar cell developed by the present invention can be widely used in the field of solar power generation, including civil and commercial rooftop power generation, power supply and charging of personal portable electronic products, and medium-scale solar cells in urban suburbs. Large-scale solar power stations connected to the grid, etc.

[0084] 1. Application of the solar cell of the present invention in the field of solar power generation

[0085] Due to the characteristics of high-efficiency multi-junction thin-film solar cells based on amorphous substrates, which are easy to integrate, high reliability...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com