Preparation method for polymer microcapsule modified emulsified bitumen

A technology of emulsified asphalt and microcapsules, which is applied to building structures, building components, building insulation materials, etc., can solve the problems of poor compatibility, long-term stability, poor emulsifier performance, and high emulsification temperature, achieving good stability, Improved performance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

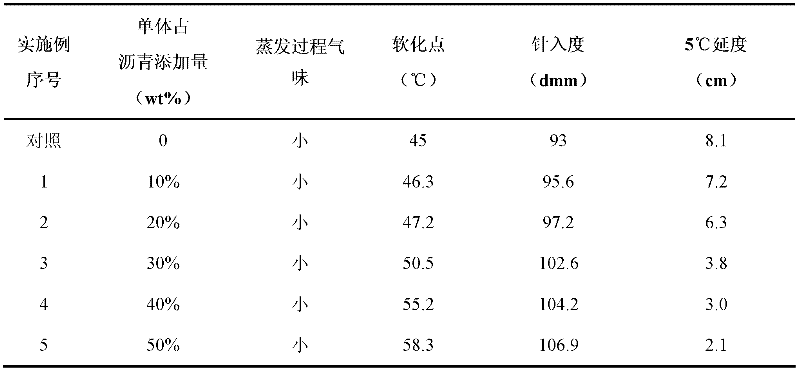

Examples

Embodiment 1

[0016] After ultrasonically mixing 400g of base asphalt with an aqueous solution containing 30g of fatty alcohol polyoxyethylene ether sodium sulfate to obtain a uniform solution, add 10g (the mixture of methacrylic acid, styrene, methyl acrylate and isocyanate, the mass ratio of each component is 2: 70: 10: 3) to swell for 2 hours, heat up to 90°C, use 3g of initiator to fully polymerize for 3 hours, add 30g of the above monomers and 10g of dibenzoyl peroxide to continue the reaction for 3 hours, cool down, filter After removing the residue, adjust the pH value of the stock solution to alkaline with NaOH to obtain polymer microcapsule-modified emulsified asphalt.

[0017] The particle size of emulsified asphalt modified by polymer microcapsules was 2180nm, and the dispersion index was 0.134.

Embodiment 2

[0019] 500g base asphalt and the aqueous solution containing 8g lauryl amidopropyl betaine are ultrasonically mixed to obtain a uniform solution, then add 20g monomer (sodium ammonium acrylate, styrene, tetrahydrofuryl methacrylate and silane mixture, the mass of each component The ratio is 11:270:100:11) to swell for 5 hours, heat up to 80°C, and after fully polymerizing with 6g of sodium persulfate for 3 hours, add 80g of the above-mentioned monomer and 20g of sodium persulfate to continue the reaction for 8 hours, cool down and filter After removing the residue, adjust the pH value of the stock solution to alkaline with NaOH to obtain polymer microcapsule-modified emulsified asphalt.

[0020] The particle size of the emulsified asphalt modified by the test polymer microcapsules is 2330nm, and the dispersion index is 0.152.

Embodiment 3

[0022] After ultrasonically mixing 300g of base asphalt with an aqueous solution containing 85g of fatty alcohol polyoxyethylene ether succinate sodium sulfonate to obtain a uniform solution, add 10g of monomers (sodium acrylate, copper acrylate, styrene, isobutyl methacrylate) The mixture with melamine (the mass ratio of each component is 10:11:570:400:31) swells for 4 hours, heats up to 85°C, and fully polymerizes with 8g of V-50 initiator for 2 hours, then adds 80g of the above-mentioned monomers Continue to react with 40g V-50 initiator for 10 hours, lower the temperature and cool down, filter off the residue and adjust the pH value of the stock solution to alkaline with NaOH to obtain polymer microcapsule modified emulsified asphalt.

[0023] The particle size of the emulsified asphalt modified by the test polymer microcapsules is 2210nm, and the dispersion index is 0.092.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com