2:17 type oxidation-resistant samarium-cobalt high-temperature permanent-magnet material and preparation method thereof

A permanent magnet material and anti-oxidation technology, which is applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problem of weakening the diffusion of oxygen elements, achieve good high-temperature oxidation resistance, improve mechanical properties and high-temperature oxidation resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

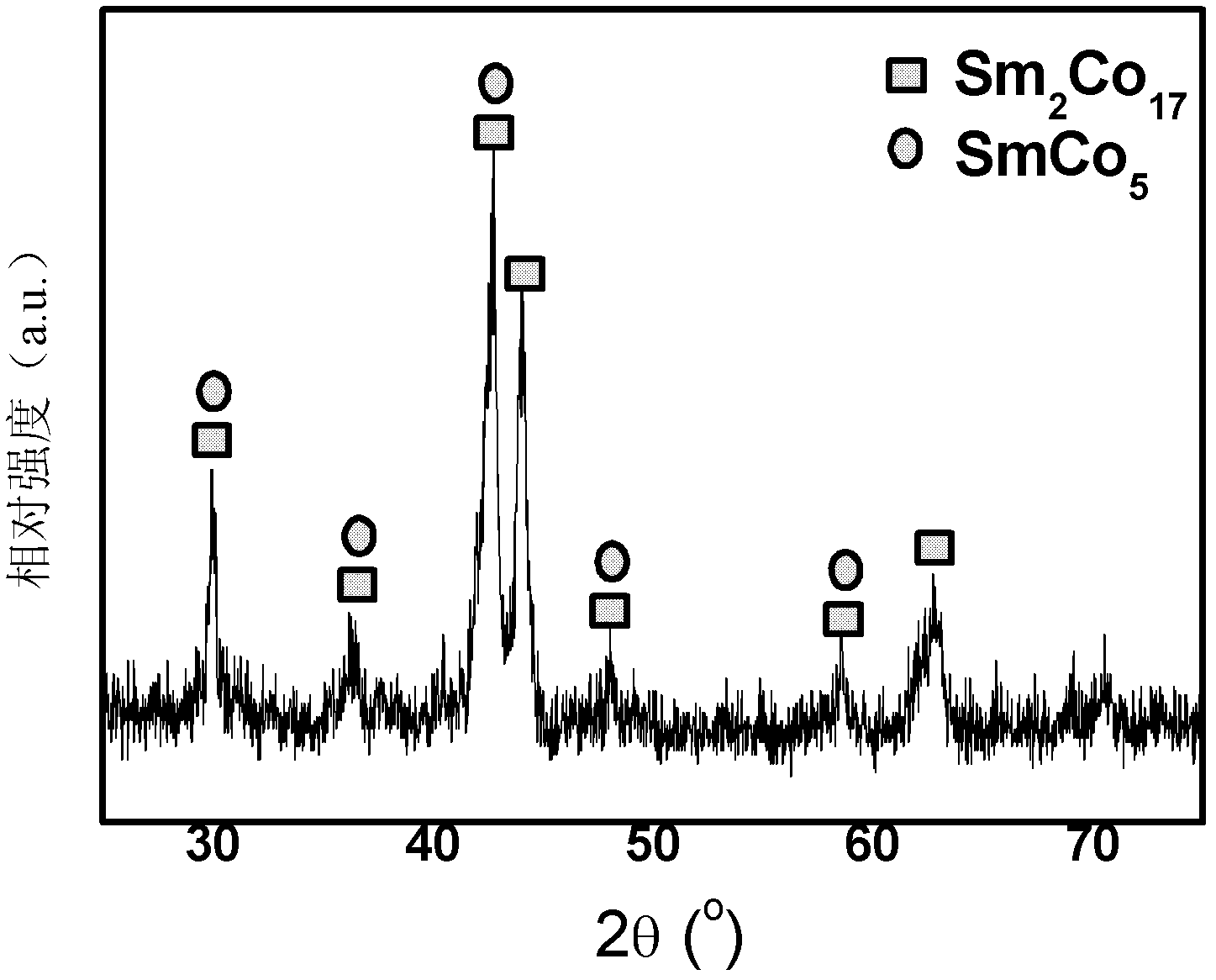

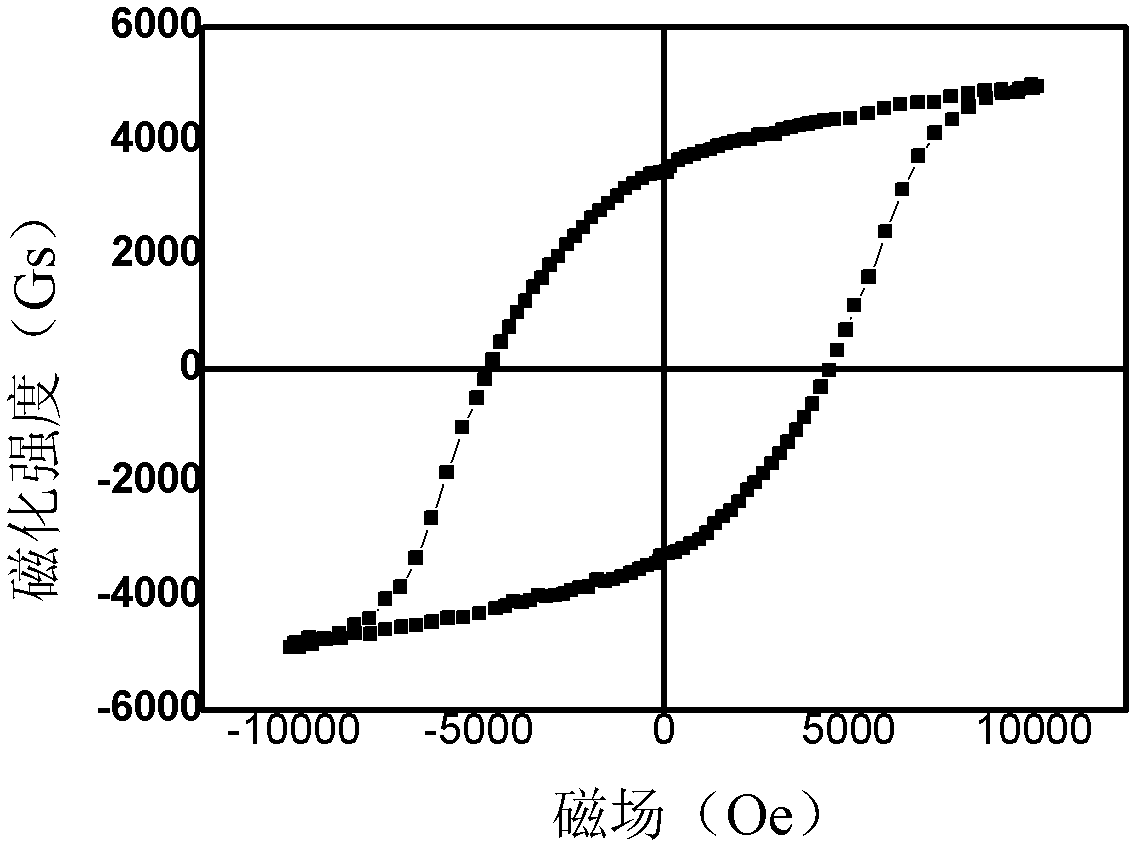

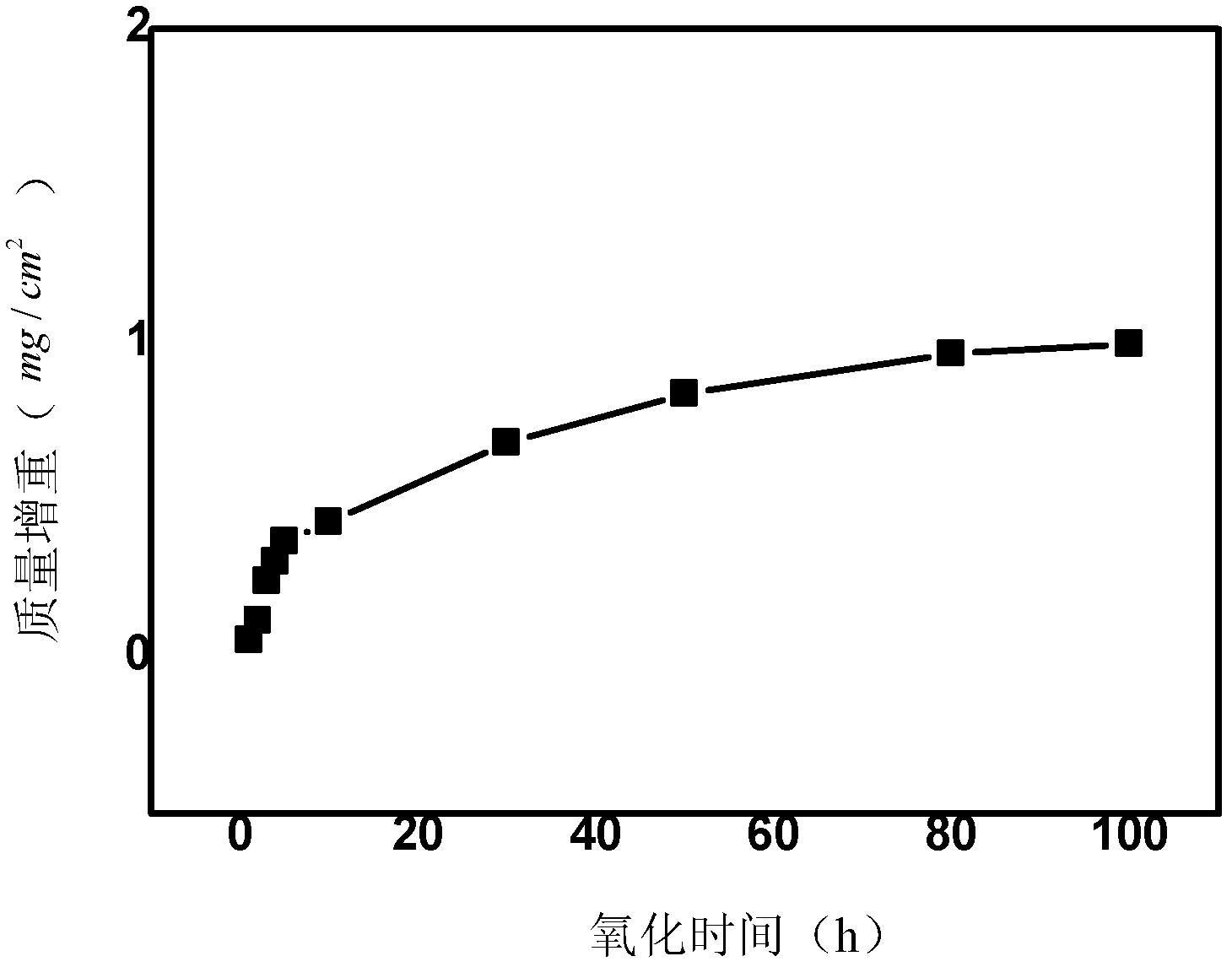

[0089] Example 1: Sm(Co 0.70 Fe 0.09 Cu 0.09 Zr 0.034 Si 0.076 sn 0.01 ) 7.61 Permanent magnet material

[0090] Step 1: Making the first target component ingot

[0091] Weighing Sm, Co, Fe, Cu, Zr and Si elements to form the first target composition;

[0092] placing the first target component in a water-cooled copper crucible of a vacuum arc melting furnace;

[0093] Adjust the vacuum degree of the vacuum chamber to 3×10 -3 Pa, then fill high-purity (mass percent purity 99.999%) argon to make the vacuum of the vacuum chamber to 0.5 × 10 5 Pa;

[0094] After arc melting for 50s, the arc is broken to form the first alloy ingot;

[0095] Turn over the first alloy ingot, and after arc melting for 50s, break the arc to form the second alloy ingot;

[0096] Turn over the second alloy ingot, and after arc melting for 50s, break the arc to form the third alloy ingot; cool with the furnace, take it out, and make the SmCoFeCuZrSi alloy ingot;

[0097] Turn over the thir...

Embodiment 2

[0135] Example 2: Sm(Co 0.73 7Fe 0.05 Cu 0.05 Zr 0.033 Si 0.1 sn 0.03 ) 6.5 Permanent magnet material

[0136] Step 1: Making the first target component ingot

[0137] Weighing Sm, Co, Fe, Cu, Zr and Si elements to form the first target composition;

[0138] placing the first target component in a water-cooled copper crucible of a vacuum arc melting furnace;

[0139] Adjust the vacuum degree of the vacuum chamber to 4×10 -3 Pa, then fill high-purity (mass percentage purity 99.999%) argon to make the vacuum of the vacuum chamber to 0.6 * 10 5 Pa;

[0140] After arc melting for 70s, the arc is broken to form the first alloy ingot;

[0141] Flip the first alloy ingot, after arc melting for 60s, break the arc to form the second alloy ingot;

[0142] Turn over the second alloy ingot, and after arc melting for 50s, break the arc to form the third alloy ingot; cool with the furnace, take it out, and make the SmCoFeCuZrSi alloy ingot;

[0143] In the present invention, ...

Embodiment 3

[0181] Example 3: Sm(Co 0.79 Fe 0.07 Cu 0.07 Zr 0.03 Si 0.02 sn 0.02 ) 8.5 Permanent magnet material

[0182] Step 1: Making the first target component ingot

[0183] Weighing Sm, Co, Fe, Cu, Zr and Si elements to form the first target composition;

[0184] placing the first target component in a water-cooled copper crucible of a vacuum arc melting furnace;

[0185] Adjust the vacuum degree of the vacuum chamber to 5×10 -3 Pa, then fill high-purity (mass percent purity 99.999%) argon to make the vacuum of the vacuum chamber to 0.8 × 10 5 Pa;

[0186] After arc melting for 90s, the arc is broken to form the first alloy ingot;

[0187] Flip the first alloy ingot, after arc melting for 90s, break the arc to form the second alloy ingot;

[0188] Turn over the second alloy ingot, and after arc melting for 90s, break the arc to form the third alloy ingot; cool with the furnace, take it out, and make the SmCoFeCuZrSi alloy ingot;

[0189] In the present invention, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com