Method for preparing p-type zinc oxide film through K-H co-doping

A zinc oxide film and zinc oxide powder technology, applied in ion implantation plating, metal material coating process, coating and other directions, can solve the problems of high film quality and low substrate temperature, and achieve controllable doping concentration , the effect of improving doping concentration and good electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

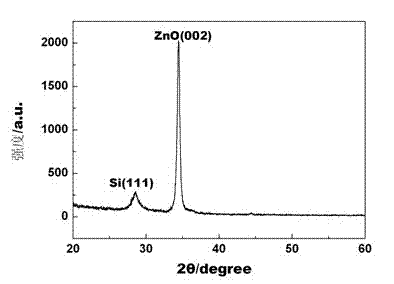

Embodiment 1

[0025] 189 grams of ZnO powder and 1 gram of KOH powder with a purity of 99.99% were mixed in a ball mill for 9 hours, and 10 grams of polyvinyl alcohol with a purity of 99.99% were added during the ball milling process to form a precursor powder of 200 grams; the precursor powder Press molding, pre-sintering at 600°C for 1.5 hours, and then sintering at 1200°C for 3 hours to prepare a KOH-doped ZnO target; the prepared KOH-doped ZnO target and the surface-cleaned single crystal silicon substrate Put them into the vacuum chamber of the pulsed laser deposition device respectively, the distance between the target and the substrate is 8cm, and the vacuum degree in the vacuum chamber is 5×10 -4 Pa; heat the substrate to 500°C, and feed a mixed gas of argon and oxygen with a purity of 99.999% into the vacuum chamber, and the partial pressure ratio of oxygen in the mixed gas is 25%; turn on the laser source in the pulsed laser deposition device, and the laser The laser beam is hit o...

Embodiment 2

[0029] 196.9 grams of ZnO powder and 0.1 gram of KOH powder with a purity of 99.99% were mixed in a ball mill for 8 hours, and 3 grams of polyvinyl alcohol with a purity of 99.99% were added during the ball milling process to form a precursor powder of 100 grams; Press molding, pre-sintering at 500°C for 2 hours, and then sintering at 1000°C for 4 hours to obtain a KOH-doped ZnO target; the prepared KOH-doped ZnO target and the surface-cleaned single crystal silicon substrate Put them into the vacuum chamber of the pulsed laser deposition device respectively, the distance between the target and the substrate is 6cm, and the vacuum degree in the vacuum chamber is 10 -4 Pa; heat the substrate to 400°C, and feed a mixed gas of argon and oxygen with a purity of 99.999% into the vacuum chamber, and the partial pressure ratio of oxygen in the mixed gas is 10%; turn on the laser source in the pulsed laser deposition device, and the laser The laser beam is hit on the target for film g...

Embodiment 3

[0032] 267 grams of ZnO powder and 3 grams of KOH powder with a purity of 99.995% were mixed in a ball mill for 10 hours, and 30 grams of polyvinyl alcohol with a purity of 99.99% were added during the ball milling process to form a precursor powder of 300 grams; Compression molding, pre-sintering at 800°C for 1 hour, and then sintering at 1300°C for 2 hours to obtain a KOH-doped ZnO target; the prepared KOH-doped ZnO target and the surface-cleaned single crystal sapphire polished sheet The substrates were respectively placed in the vacuum chamber of the pulsed laser deposition device, the distance between the target and the substrate was 10 cm, and the vacuum degree in the vacuum chamber was 10 -3 Pa; heat the substrate to 600°C, and pass a mixture of argon and oxygen with a purity of 99.9995% into the vacuum chamber, and the partial pressure ratio of oxygen in the mixture is 40%; turn on the laser source in the pulsed laser deposition device, and the laser The laser beam is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com