A polymer particle integrated foam molding process

A foam molding and polymer technology, applied in the field of polymer foam material preparation, can solve problems such as uneven distribution of molds, adhesion of foamed particles, etc., to solve the problem of poor welding, consistent particle temperature, and uniform internal welding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment provides a foam pretreatment device and a foam molding device.

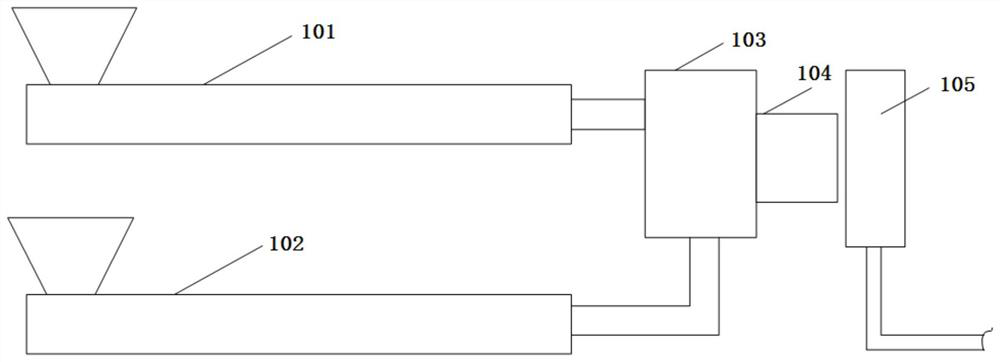

[0037] Such as figure 1 Said, a foaming pretreatment device, wherein, the first extruder 101 and the second extruder 102 are twin-screw extruders, the outlets of which are respectively connected to the two feeding ports of the distributor 103, and the distribution A die head 104 is installed at the outlet of the device 103 and is connected with an underwater hot cutting granulation system 105 .

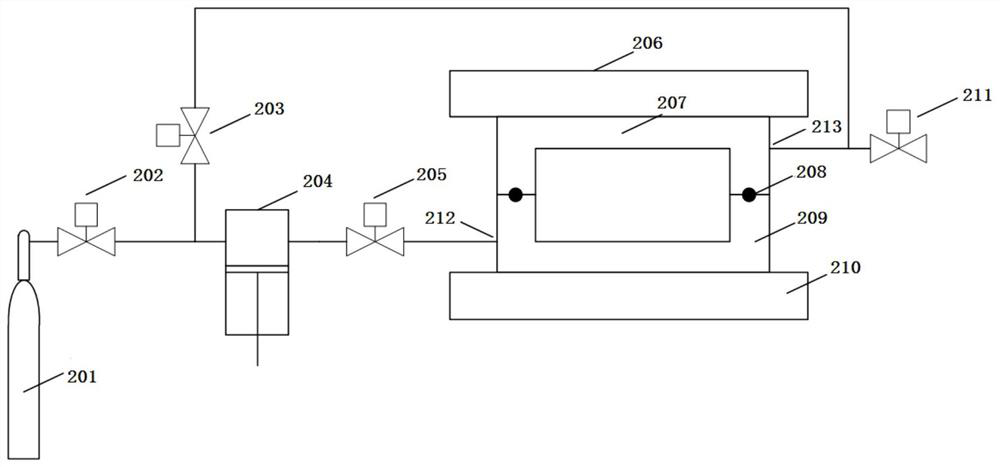

[0038] Such as figure 2 As shown, a foam molding device, wherein the upper mold 207 and the lower mold 209 are respectively installed on the upper hot plate 206 and the lower hot plate 210 of the hydraulic press, and are sealed by the sealing ring 208 through the hydraulic press. The steel cylinder 201 and the booster pump 204 are connected by a pipeline, and a steel cylinder intake valve 202 is installed on the pipeline between the two; the booster pump 204 and the air inlet 212 on the lower mo...

Embodiment 2

[0040] This embodiment provides an integrated foam molding process for polymer particles, wherein the material to be foamed is polypropylene resin (PP), comprising the following steps:

[0041](1) Add polypropylene resin (PP) with a number average molecular weight of 200,000 and a melting point of 160°C to the first extruder 101, and add PP with a number average molecular weight of 100,000 and a melting point of 140°C to the second extruder 102 Inside, the mass ratio of the two resins is 5:1, which are respectively melted by the screw in the extruder, and then extruded into the distributor 103. In the distributor 103, the PP with a melting point of 140°C is packaged with the PP with a melting point of 160°C. After that, it is extruded from the die head 104, and hot-cut and granulated in the underwater hot-cut granulation system 105. The granulation temperature is 80°C, and the polymerization of PP with a melting point of 160°C in the core and PP with a melting point of 140°C in...

Embodiment 3

[0044] This embodiment provides an integrated foam molding process for polymer particles, wherein the material to be foamed is polyether polyurethane elastomer (TPU), comprising the following steps:

[0045] (1) Add polyether polyurethane elastomer (TPU) with a number average molecular weight of 250,000 and a melting point of 153°C into the first extruder 101, and add TPU with a number average molecular weight of 170,000 and a melting point of 138°C into the second extruder In the extruder 102, the mass ratio of the two resins is 25:1. They are respectively melted by the screw in the extruder, and then extruded into the distributor 103. In the distributor 103, the ratio of TPU with a melting point of 138 ° C to that of TPU with a melting point of 153 ° C is realized. The coating of TPU is then extruded from the die head 104, and then hot-cut and granulated in the underwater hot-cut granulation system 105. The granulation temperature is 60°C, and the TPU with the melting point o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com