Chromate and chromium sesquioxide multiferroic nanometer composite material and preparation method thereof

A technology of chromium trioxide multiferroic, nano-composite material, applied in the directions of chromium trioxide, chromium oxide/hydrate, chromate/dichromate, etc., to achieve the effects of short cycle, low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A method for preparing a chromate and chromium oxide multiferroic nanocomposite material provided by an embodiment of the present invention comprises the following steps:

[0029] Step A. Configure the mixed solution of transition metal ions containing chromium: select transition metal nitrate as raw material, preferably, adopt any one of copper nitrate, nickel nitrate or cobalt nitrate as raw material, ammonium bicarbonate as precipitant, wherein nitric acid Chromium as antiferromagnetic Cr 2 o 3 The ion source, the transition metal nitrate as the multiferroic chromate oxide MCr 2 o 4 (wherein, M represents a magnetic transition metal, when using copper nitrate as a raw material, M=Cu; when using nickel nitrate as a raw material, M=Ni; when using cobalt nitrate as a raw material, M=Co), molar Dissolve transition metal nitrate and chromium nitrate in deionized water, prepare a solution with a concentration of chromium ions of 0.2-0.6 mol / L, wherein the chemical molar...

Embodiment 1

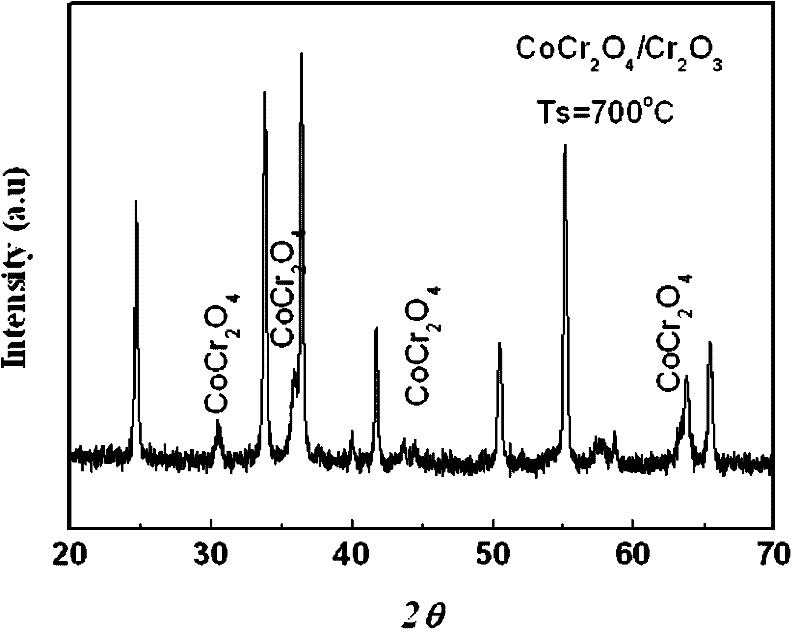

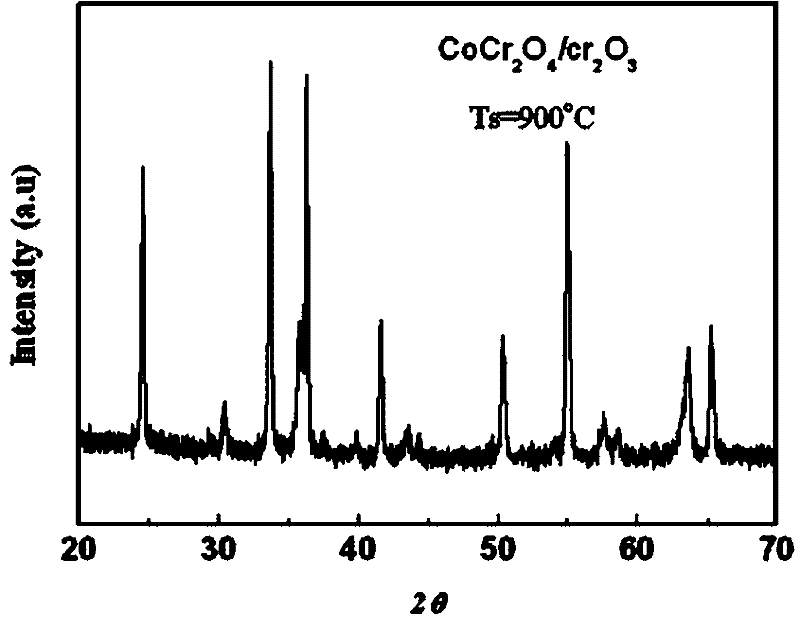

[0035] Ferromagnetic CoCr with a sintering temperature of 900 °C was prepared as described above 2 o 4 and antiferromagnetic Cr 2 o 3 nanocomposite materials. The first step is to weigh cobalt nitrate and chromium nitrate according to the chemical molar ratio of cobalt ion and chromium ion being 1:50, wherein the cobalt nitrate is 0.001mol, and the chromium nitrate is 0.05mol. After mixing, they are dissolved in deionized water and configured as chromium ions A mixed solution of metal ions with a concentration of 0.5mol / L; in the second step, weigh 0.2mol ammonium bicarbonate according to the stoichiometric ratio, dissolve it in a beaker, and configure it into a solution of 0.8mol / L; under constant stirring, mix the metal ions The mixed solution was dropped into the ammonium bicarbonate solution to form a precipitate; in the third step, the precipitate was filtered and washed 8 times, and then dried in an oven at 150°C until a dry powder was obtained; in the fourth step, th...

Embodiment 2

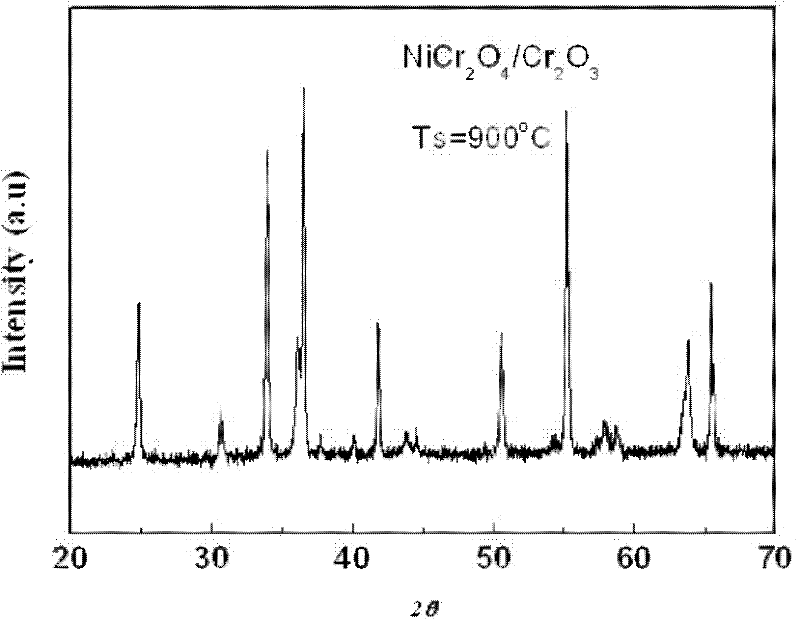

[0037] Ferromagnetic NiCr with a sintering temperature of 700 °C was prepared according to the above method 2 o 4 and antiferromagnetic Cr 2 o 3 nanocomposite materials. The first step is to weigh nickel nitrate and chromium nitrate according to the chemical molar ratio of nickel ions and chromium ions as 1:10, wherein the nickel nitrate is 0.005mol, and the chromium nitrate is 0.05mol. After mixing, they are dissolved in deionized water and configured as chromium ions A metal ion mixed solution with a concentration of 0.5mol / L; in the second step, weigh 0.2mol ammonium bicarbonate according to the stoichiometric ratio, dissolve it in a beaker, and configure it into a 0.6mol / L solution, and the ammonium bicarbonate should be over 30%; Under constant stirring, drop the metal ion mixed solution into the ammonium bicarbonate solution to form a precipitate; the third step is to filter and wash the precipitate for 12 times, and then dry it in an oven at 120°C until a dry powder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com