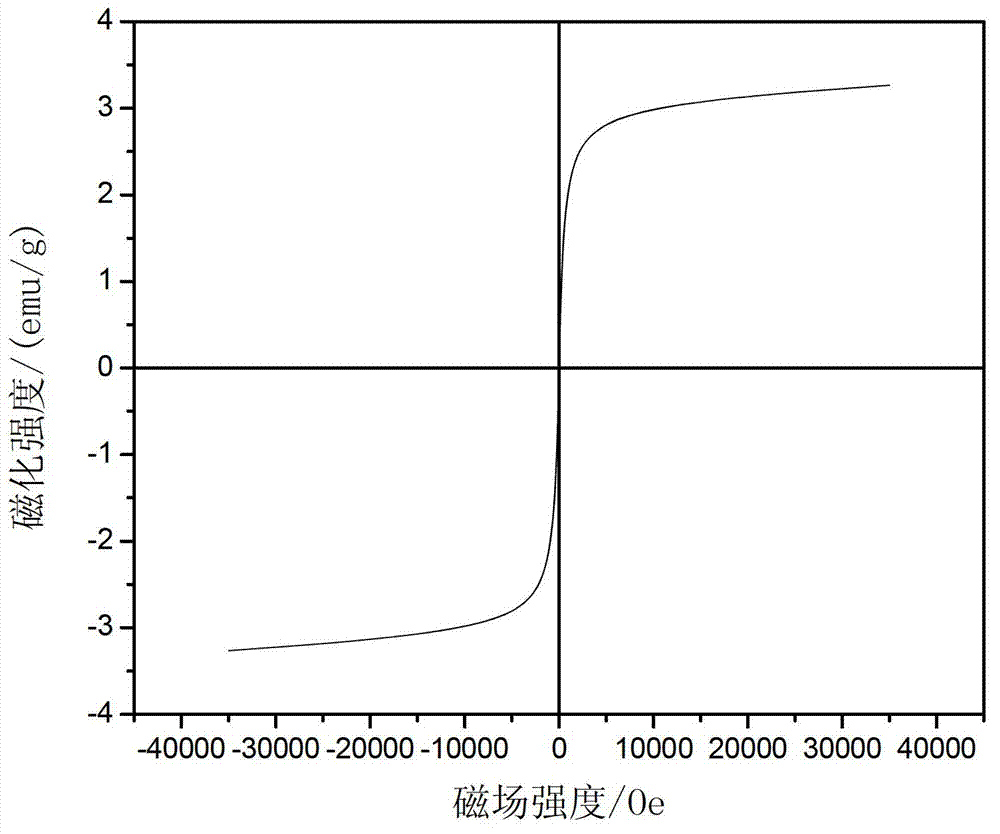

Fe3O4/TiO2 nano magnetic composition and in-situ growing preparation method thereof

A nano-magnetic, in-situ growth technology, applied in the direction of nano-magnetism, nano-technology, nano-technology, etc., can solve the problems of impure nano-composite particles, high requirements for equipment, complicated preparation methods, etc., and achieve components and properties Ease of control, energy saving, and the effect of lowering the reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of the titanium oxide organic matter is:

[0032] (1) Mix 20mL butyl titanate, 20mL acetic anhydride and 50mL cyclohexane evenly, place in a glass container, heat to 70°C, the reaction mixture gradually becomes white turbid; min) centrifugation, and the solid was washed several times with acetone to obtain titanyl organic powder.

Embodiment 1

[0034] (1) Take 50mL of distilled water and heat it to remove the dissolved oxygen, place it in a constant temperature water bath at a constant temperature of 50°C; add 2.98g of FeCl 2 4H 2 O and 8.11 g FeCl 3 ·6H 2 0, at this moment the solution turned yellowish brown, vigorous stirring made the whole reaction system mix evenly;

[0035] (2) Drop an appropriate amount of ammonia water into the mixture under strong stirring, and stop the drop when the pH of the reaction solution is 11; stir at 450rpm for 60 minutes, then ultrasonically disperse for 30 minutes, and centrifugally wash until pH=7 to obtain black Fe 3 o 4 Precipitation, spare.

[0036] (3) Weigh 15.92g of titanyl organic matter into a flask, add 290.5g of 0.5mol / L nitric acid solution at the same time, stir to fully dissolve the titanyl organic matter, and obtain a mixed solution A;

[0037] (4) Fe will be prepared 3 o 4 Precipitate, mix in mixed solution A, stir at 350rpm to disperse the whole system evenl...

Embodiment 2

[0039] (1) Take 50mL of distilled water and heat it to remove the dissolved oxygen, place it in a constant temperature water bath at a constant temperature of 50°C; add 2.98g of FeCl 2 4H 2 O and 8.11 g FeCl 3 ·6H 2 0, at this moment the solution turned yellowish brown, vigorous stirring made the whole reaction system mix evenly;

[0040] (2) Drop an appropriate amount of ammonia water into the mixture under strong stirring, and stop the drop when the pH of the reaction solution is 11; stir at 450rpm for 60 minutes, then ultrasonically disperse for 30 minutes, and centrifugally wash until pH=7 to obtain black Fe 3 o 4 Precipitation, spare.

[0041] (3) Weigh 15.92g of titanyl organic matter into a flask, add 290.5g of 0.5mol / L nitric acid solution at the same time, stir to fully dissolve the titanyl organic matter, and obtain a mixed solution A;

[0042] (4) Fe will be prepared 3 o 4 Precipitate, mix in mixed solution A, stir at 350rpm to disperse the whole system evenl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com