Easily processed and quickly crosslinked silane crosslinked polyethylene insulating material and preparation method thereof

A technology of cross-linking polyethylene and bi-silane, which is used in organic insulators, plastic/resin/wax insulators, etc., can solve the problems of narrow processing temperature range, corroded equipment, pre-crosslinking, etc. The effect of joint curing and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Material A: the density is 0.918g / cm 3 100 parts of polyethylene, 5 parts of ethylene-methyl acrylate copolymer with a mass content of 21.5% of methyl acrylate, 2.5 parts of vinyltriethoxysilane, and 0.15 parts of di-tert-butyl peroxide are passed through a twin-screw extruder Reactive extrusion granulation, drying after cooling to obtain material A;

[0034] Material B: 100 parts of ethylene-acrylic acid copolymer with a mass content of 8.5% of acrylic acid, 4 parts of catalyst dioctyltin dilaurate, 4 parts of white carbon black, antioxidant tetrakis[methyl-β-(3,5-di 2 parts of tert-butyl-4-hydroxyphenyl propionate] pentaerythritol ester, 4 parts of lubricant polyethylene wax, and 2 parts of copper inhibitor. Blending and granulation by a twin-screw extruder, air cooling, and drying to obtain material B.

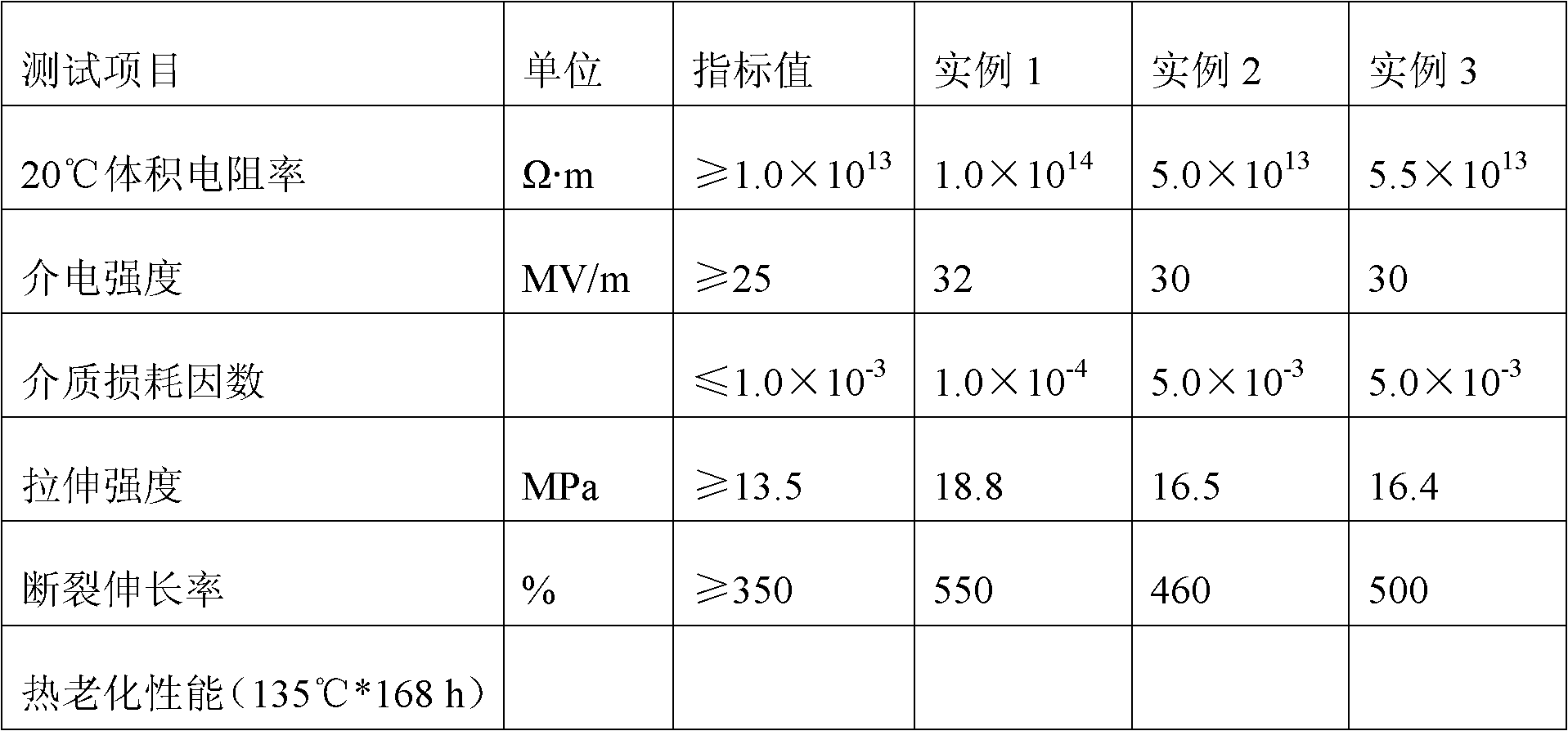

[0035] Mix according to the ratio of material A: material B = 95:5 to obtain a rapidly cross-linking silane cross-linked polyethylene insulating material. JB / T102...

Embodiment 2

[0037] Material A: the density is 0.920g / cm 3 100 parts of polyethylene, 10 parts of ethylene-methyl acrylate copolymer with a mass content of 9% of methyl acrylate, 4 parts of vinyltriethoxysilane, 2,5-dimethyl-2,5-bis(tert Butyl peroxy) hexane 0.2 part, production technology is with embodiment 1;

[0038] Material B: 100 parts of ethylene-acrylic acid copolymer with a mass content of 9.7% of acrylic acid, 4 parts of catalyst dibutyltin diacetate, 2 parts of white carbon black, antioxidant β-(3,5-di-tert-butyl-4- 1 part of n-octadecyl hydroxyphenyl) propionate, 5 parts of lubricant silicone masterbatch, 3 parts of copper inhibitor. Blending and granulation by a twin-screw extruder, air cooling, and drying to obtain material B. The production process is the same as in Example 1.

[0039] Mix according to the mass ratio of material A: material B = 97: 3 to obtain a rapid cross-linking silane cross-linked polyethylene insulating material. JB / T 10260-2001 standard was used for...

Embodiment 3

[0041] Material A: the density is 0.923g / cm 3 100 parts of polyethylene, 10 parts of ethylene-butyl acrylate copolymers with a mass content of butyl acrylate of 27%, 4 parts of vinyltriethoxysilane, and 0.2 part of dibenzoyl peroxide, the production process is the same as in Example 1 ;

[0042] Material B: 100 parts of ethylene-acrylic acid copolymer with a mass content of 7.0% of acrylic acid, 3 parts of catalyst dibutyltin dilaurate, 4 parts of white carbon black, antioxidant 4,4'-thiobis(6-tert-butyl Base-3-methylphenol) 1 part, lubricant silicone oil 2 parts, copper inhibitor 3 parts. Blending and granulation by a twin-screw extruder, air cooling, and drying to obtain material B. The production process is the same as in Example 1.

[0043] Mix according to the weight ratio of material A: material B = 95:5 to obtain a rapidly cross-linking silane cross-linked polyethylene insulating material. JB / T 10260-2001 standard was used for testing, and the results are shown in Ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com