Soft metal-friendly resin-based friction material and preparation method thereof

A kind of friction material and friendly technology, which is applied in the field of soft metal-friendly resin-based friction material and its preparation, can solve the problems of environmental protection, energy saving and large energy consumption without resin-based friction materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

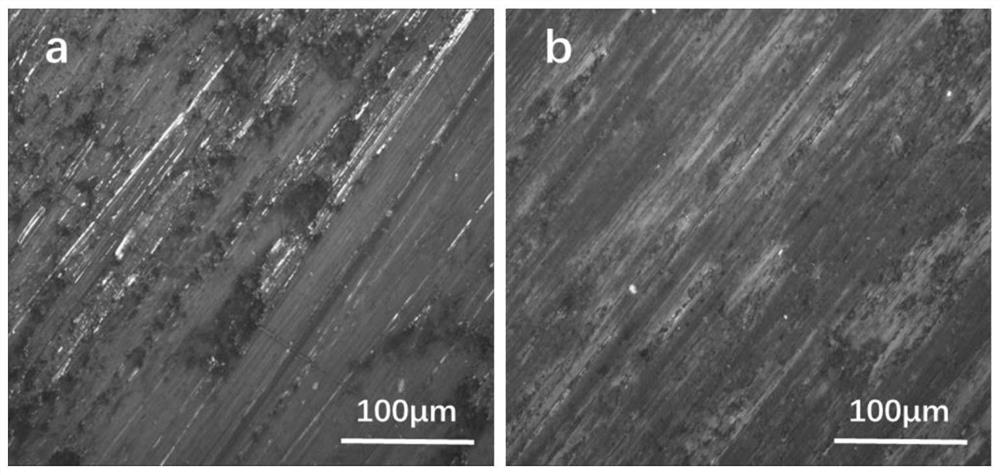

Image

Examples

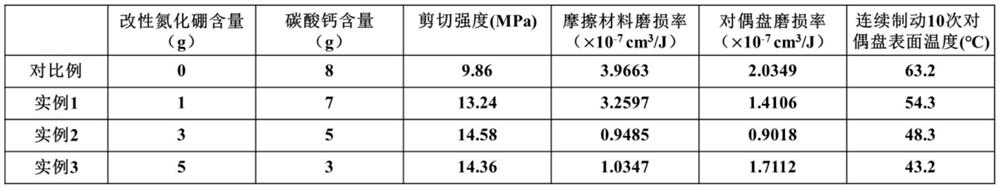

Embodiment 1

[0034] Step 1: Measure 500ml of deionized water, use Tris and concentrated hydrochloric acid to adjust the pH of the solution to 8.5, add 1g of dopamine hydrochloride and 10g of hexagonal boron nitride successively, and stir at room temperature for 24 hours. Afterwards, the hexagonal boron nitride is filtered and washed, and dried in a vacuum oven at 60-80° C. to obtain surface-modified boron nitride powder.

[0035] Step 2: Weigh 24.00 g of reinforcing fiber, 12.00 g of phenolic resin, 8.00 g of nitrile rubber, and 56.00 g of filler and friction modifier. Wherein, the filler includes 1.00 g of modified boron nitride and 7.00 g of calcium carbonate. The above raw materials are mixed at a high speed to obtain a flocculent mixture.

[0036] Step 3: Weigh 15.47g of the flocculent mixture, fill it evenly into a steel mold, and press it at a pressure of 5MPa and a temperature of 160°C for 600s to obtain a thickness of about 3mm and a density of 2g / cm 3 ring prefab.

[0037] Step...

Embodiment 2

[0039] Step 1: Measure 500ml of deionized water, use Tris and concentrated hydrochloric acid to adjust the pH of the solution to 8.5, add 1g of dopamine hydrochloride and 10g of hexagonal boron nitride successively, and stir at room temperature for 24 hours. Afterwards, the hexagonal boron nitride is filtered and washed, and dried in a vacuum oven at 60-80° C. to obtain surface-modified boron nitride powder.

[0040] Step 2: Weigh 24.00 g of reinforcing fiber, 12.00 g of phenolic resin, 8.00 g of nitrile rubber, and 56.00 g of filler and friction modifier. Wherein, the filler includes 3.00 g of modified boron nitride and 5.00 g of calcium carbonate. The above raw materials are mixed at a high speed to obtain a flocculent mixture.

[0041] Step 3: Weigh 15.47g of the flocculent mixture, fill it evenly into a steel mold, and press the mold at a pressure of 5MPa and a temperature of 160°C for 600s to obtain a thickness of about 3mm and a density of 2g / cm 3 ring prefab.

[0042...

Embodiment 3

[0044] Step 1: Measure 500ml of deionized water, use Tris and concentrated hydrochloric acid to adjust the pH of the solution to 8.5, add 1g of dopamine hydrochloride and 10g of hexagonal boron nitride successively, and stir at room temperature for 24 hours. Afterwards, the hexagonal boron nitride is filtered and washed, and dried in a vacuum oven at 60-80° C. to obtain surface-modified boron nitride powder.

[0045] Step 2: Weigh 24.00 g of reinforcing fiber, 12.00 g of phenolic resin, 8.00 g of nitrile rubber, and 56.00 g of filler and friction modifier. Wherein, the filler includes 5.00 g of modified boron nitride and 3.00 g of calcium carbonate. The above raw materials are mixed at a high speed to obtain a flocculent mixture.

[0046] Step 3: Weigh 15.47g of the flocculent mixture, fill it evenly into a steel mold, and press the mold at a pressure of 5MPa and a temperature of 160°C for 600s to obtain a thickness of about 3mm and a density of 2g / cm 3 ring prefab.

[0047...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com