Whisker modified polymethacrylimide foamed plastic and preparation method thereof

A technology of polymethacrylimide and foamed plastics, which is applied in the field of whisker-modified polymethacrylimide foamed plastics and its preparation, can solve the problems of difficulty in realizing enlarged production, loss of performance, etc., and achieves a reduction in flammability The effect of reducing smoke density and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

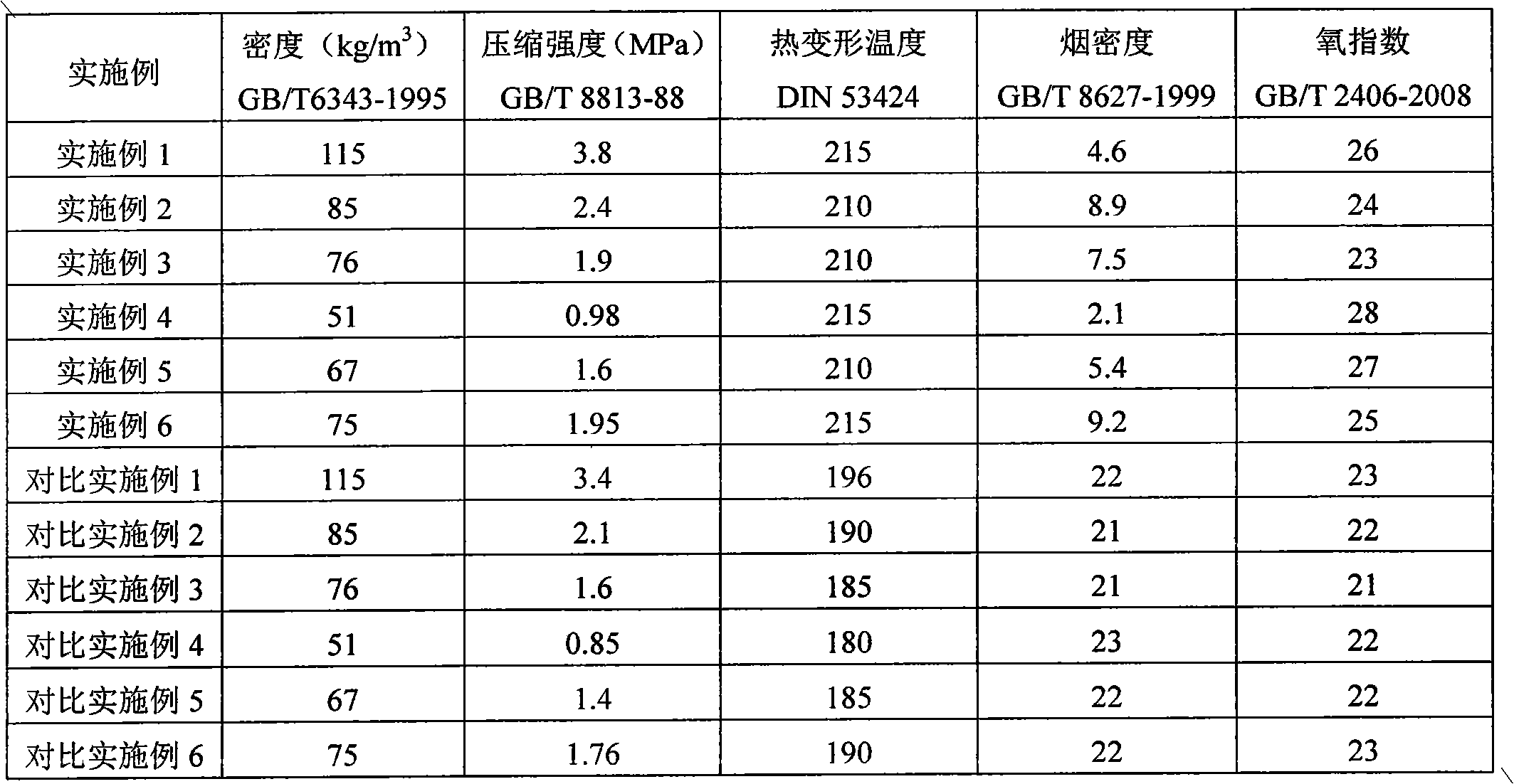

Examples

Embodiment 1

[0045] Whisker modified polymethacrylimide foamed plastics of the present invention, it is to adopt following raw materials to make by weight ratio:

[0046] 60 parts of methacrylic acid

[0047] 40 parts of methacrylonitrile

[0048] 1 part magnesium salt whiskers

[0049] Thixotropic agent polymethyl methacrylate 2 parts

[0050] Nucleating agent silicon dioxide 0.1 part

[0051] Initiator dibenzoyl peroxide 0.1 parts

[0052] Initiator peroxy-2-ethyl-hexanoic acid tert-butyl ester 0.05 parts

[0053] Foaming agent formamide 0.1 part

[0054] Cross-linking agent allyl acrylate 0.1 parts

[0055] Retarder benzoquinone 0.01 parts

[0056] The preparation method of whisker modified polymethacrylimide foam plastic of the present invention, comprises the steps:

[0057] (1) The above-mentioned raw materials are weighed according to the above-mentioned specific gravity, mixed at a high speed at normal temperature, and the dispersion of the magnesium salt whiskers is streng...

Embodiment 2

[0062] Whisker modified polymethacrylimide foamed plastics of the present invention, it is to adopt following raw materials to make by weight ratio:

[0063] Acrylic 30 parts

[0064] 70 parts of methacrylonitrile

[0065] Silicon carbide whiskers 0.1 parts

[0066] Thixotropic polyamide wax 2 parts

[0067] Nucleating agent tert-butyl acrylate 1 part

[0068] Initiator azobisisobutyronitrile (AIBN) 0.05 parts

[0069] Foaming agent isopropyl alcohol 2 parts

[0070] Cross-linking agent allyl methacrylamide 1 part

[0071] 0.07 part of retarder anisole peroxide

[0072] The preparation method of whisker modified polymethacrylimide foam plastic of the present invention, comprises the steps:

[0073] (1) The above-mentioned raw materials are weighed according to measurement, mixed at a high speed at room temperature, and the dispersion of the whisker material is strengthened by power ultrasonic waves, and the whisker material is surface-activated by a titanate coupling ag...

Embodiment 3

[0078] Whisker modified polymethacrylimide foamed plastics of the present invention, it is to adopt following raw materials to make by weight ratio:

[0079] 70 parts of methacrylic acid

[0080] Acrylonitrile 30 parts

[0081] Calcium Sulfate Whiskers 10 parts

[0082] Thixotropic agent hydrogenated castor oil 0.1 parts

[0083] Nucleating agent zinc sulfide 2 parts

[0084] Initiator peroxy-2-ethyl-hexanoic acid tert-butyl ester 2 parts

[0085] Foaming agent oxalic acid 4 parts

[0086] Cross-linking agent magnesium oxide 0.01 parts

[0087] Retarder hydroquinone 0.04 parts

[0088] The preparation method of whisker modified polymethacrylimide foam plastic of the present invention, comprises the steps:

[0089] (1) The above-mentioned raw materials are weighed according to measurement, mixed at a high speed at normal temperature, and the dispersion of the whisker material is strengthened by power ultrasonic waves, and the whisker material is surface-activated by an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com