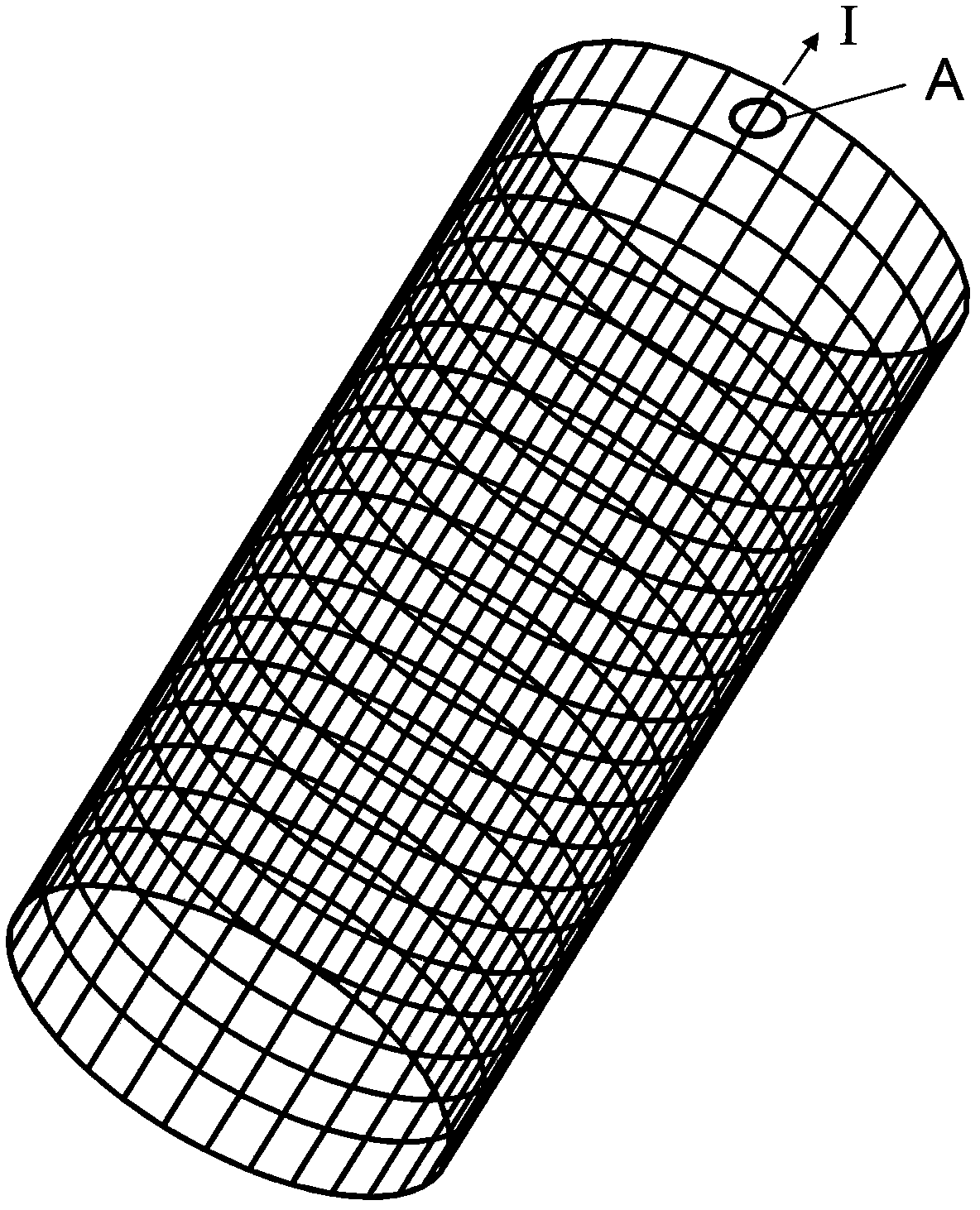

Biodegradable stent composite material and preparation method thereof

A composite material and a biodegradable technology, applied in the field of biodegradable stent composite materials and their preparation, can solve the problems of excessive local heat generation, poor degradation controllability, accumulation of acidic degradation products, etc., and achieve a simple and practical preparation method and easy industrialization. The effect of production, increasing variety and quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

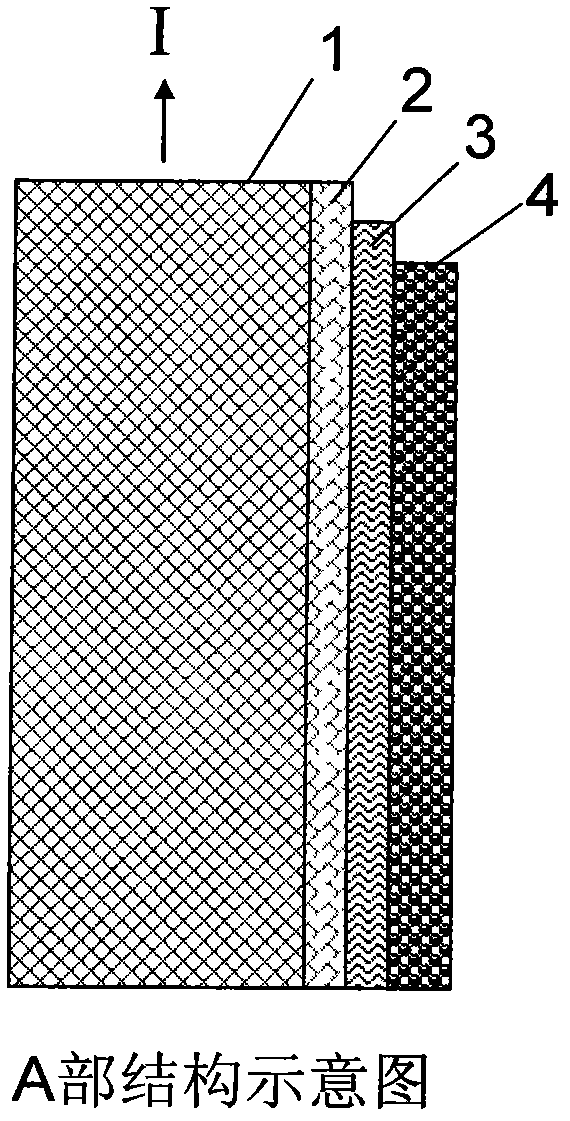

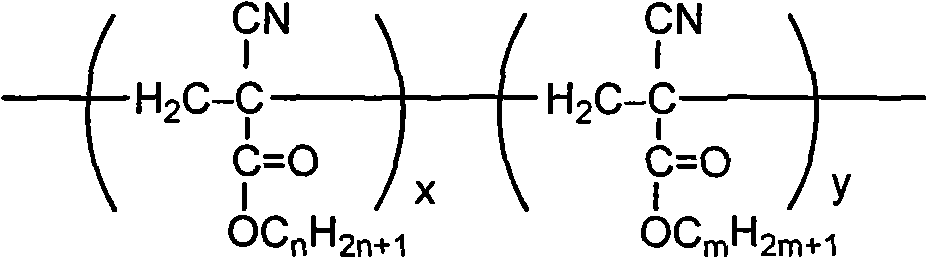

Method used

Image

Examples

Embodiment 1

[0057] (1) Select high-purity magnesium metal with a purity greater than 99.9%, and carry out ultrasonic cleaning with acetone, absolute ethanol, and deionized water for 20 minutes successively to remove surface oil stains; use 280~1000# metallographic sandpaper to polish step by step, and then use them separately Ultrasonic cleaning with ionized water and absolute ethanol for 20 minutes, and then drying; soaking in 10% nitric acid-methanol solution for chemical polishing, and rinsing with deionized water after removal.

[0058] (2) Prepare 30% HF acid solution, soak magnesium metal in the solution for 24 hours, then ultrasonically clean with deionized water and absolute ethanol for 10 minutes and dry to form medical metal matrix 1 .

[0059] (3) Prepare a vinyltriethoxysilane / ethanol solution with a concentration of 1%, add acetic acid as a catalyst, and adjust the pH value to 3.5-5.5; soak the sample in the solution for 60 seconds, and put it in the Put it into an oven for h...

Embodiment 2

[0064] (1) Select a magnesium-zirconium alloy with a magnesium content of 85%, and carry out ultrasonic cleaning with acetone, absolute ethanol, and deionized water for 20 minutes in turn to remove surface oil stains; use 280~1000# Metallographic sandpaper to polish step by step, and then respectively Ultrasonic cleaning with deionized water and absolute ethanol for 20 minutes, and then drying; soaking in 10% nitric acid-methanol solution for chemical polishing, rinsed with deionized water after removal.

[0065] (2) Prepare 40% HF acid solution, soak the magnesium alloy in the solution for 24 hours, then ultrasonically clean with deionized water and absolute ethanol for 10 minutes and dry.

[0066] (3) Prepare an aminopropyltriethoxysilane / isopropanol solution with a concentration of 1%, add acetic acid as a catalyst, and adjust the pH value to 3.5-5.5; soak the sample in the solution for 60 seconds, and wait for it to dry Finally, put it into an oven for heating and aging at...

Embodiment 3

[0071] (1) Choose a magnesium-manganese alloy with a magnesium content of 95%, and use acetone, absolute ethanol, and deionized water to perform ultrasonic cleaning for 20 minutes each to remove surface oil; use 280~1000# Metallographic sandpaper to polish step by step, and then Ultrasonic cleaning with deionized water and absolute ethanol for 20 minutes, and then drying; soaking in 10% nitric acid-methanol solution for chemical polishing, rinsed with deionized water after removal.

[0072] (2) Prepare 35% HF acid solution, soak the magnesium alloy in the solution for 24 hours, then ultrasonically clean with deionized water and absolute ethanol for 10 minutes and dry.

[0073] (3) Prepare a vinyltriethoxysilane / ethanol solution with a concentration of 2%, add acetic acid as a catalyst, and adjust the pH value to 3.5-5.5; soak the sample in the solution for 60 seconds. Heat and age in an oven at 90°C for 60 minutes, then cool to room temperature with the furnace.

[0074] (4) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com