Solvent-containing high-temperature corrosion-resistant flame-resistant anti-fouling thermoplastic resin

A thermoplastic resin and corrosion-resistant technology, which is applied in the fields of thermoplastic resin synthesis, heat resistance, resin corrosion resistance, and flame-retardant modification. It can solve problems such as bond strength, impact resistance, and sudden temperature change, and achieve good product stability. , good flame retardant properties, the effect of improving high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] In reactor, add 65% bisphenol A epoxy resin, 35% adipic acid, heating temperature is 75 ℃, then add 0.5% catalyzer (the quality formula of dibenzoyl peroxide, inorganic base, organic amine) The ratio is: 76.57: 5.56: 17.87, the inorganic base is sodium hydroxide, the triethanolamine in the organic amine is 5% by mass of the catalyst), 0.01% hydroquinone; heat up to 110°C, time the reaction for 45 minutes, and cool down , and add 20% butanone to the polymer, stir, take out, and obtain a reddish-brown transparent liquid.

[0045] The performance index of embodiment gained resin:

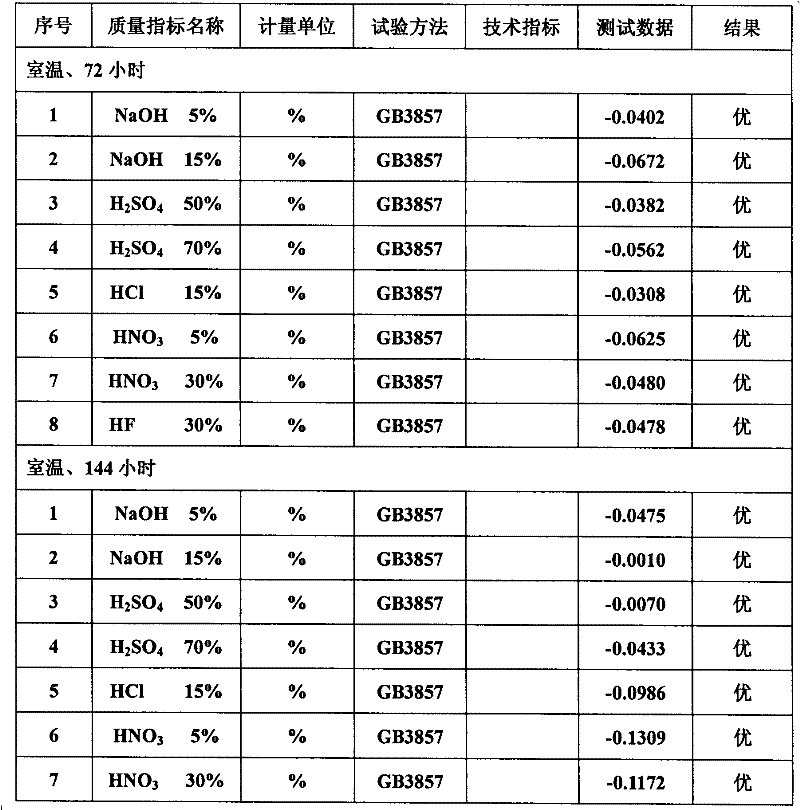

[0046] Bond strength is 14.7MPa, impact strength is 136.4KJ / m 2 , the elongation at break is 10.2%, the heat distortion temperature is 515°C, the flame retardant performance (GB2408): 45mm, class II, and the corrosion resistance performance is shown in the following table:

[0047] Table 1 is according to the resin corrosion resistance of the present invention gained

[0048]

[0049]

Embodiment 2

[0051] In reactor, add 70% novolac epoxy varnish, 30% adipic acid, heating temperature is 73 ℃, then adds 1.5% catalyzer (the mass proportion of dibenzoyl peroxide, inorganic base, organic amine is : 71.03: 3.62: 25.35, the inorganic base is potassium hydroxide, triethanolamine is the 5.8 mass % of catalyst), 0.02% methyl hydroquinone in the organic amine; Heating is warming up to 105 ℃ ℃, timing reaction 47 minutes, wait The viscosity of the polymer changes, the temperature is lowered, and 25% ethylene glycol butyl ether is added to the polymer, stirred, and taken out to obtain a reddish-brown transparent liquid.

[0052] The performance index of embodiment gained resin:

[0053] Bond strength is 13.5MPa, impact strength is 130.2KJ / m 2 , The elongation at break is 9.5%, and the heat distortion temperature is 564°C.

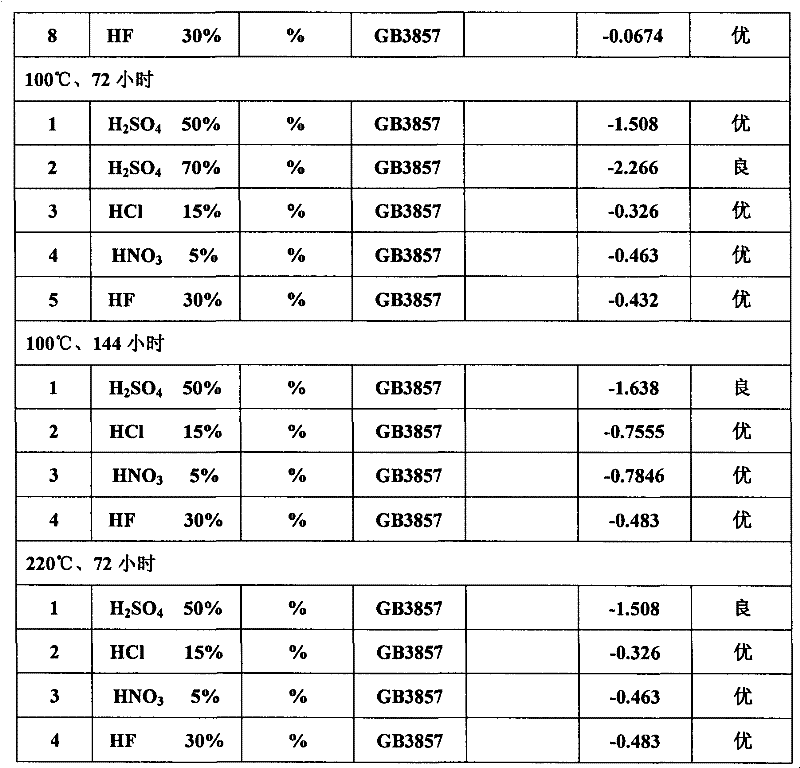

[0054] Flame retardant performance (GB2408): 37mm, class II, corrosion resistance performance as shown in the table below:

[0055] Table 2 is according to th...

Embodiment 3

[0060] Add 70% epoxy resin (bisphenol A epoxy resin: novolac epoxy=4:6) in reactor, 30% tetrabromophthalic anhydride, heating temperature is 80 ℃, add 1.0% again Catalyst (the mass ratio of dibenzoyl peroxide, inorganic base, and organic amine is: 64.43: 7.29: 28.28, the inorganic base is potassium hydroxide, and triethanolamine is 6.2% by mass of the catalyst in the organic amine), 0.03% para Hydroquinone: heat up to 117° C., time the reaction for 50 minutes, wait for the viscosity of the polymer to change, lower the temperature, add 22% butanone to the polymer, stir, take out, and obtain a reddish-brown transparent liquid.

[0061] The performance index of embodiment gained resin:

[0062] Bond strength is 14.2MPa, impact strength is 132.3KJ / m 2 , The elongation at break is 9.7%, and the heat distortion temperature is 542°C.

[0063] Flame retardant performance (GB2408): 29mm, class II, corrosion resistance performance as shown in the table below:

[0064] Table 3 is acco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com