Lining of water heater with antiscaling performance

A water heater liner and performance technology, applied in the coating and other directions, can solve problems such as affecting the safety of electricity consumption, perforation and water leakage of the water heater liner, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

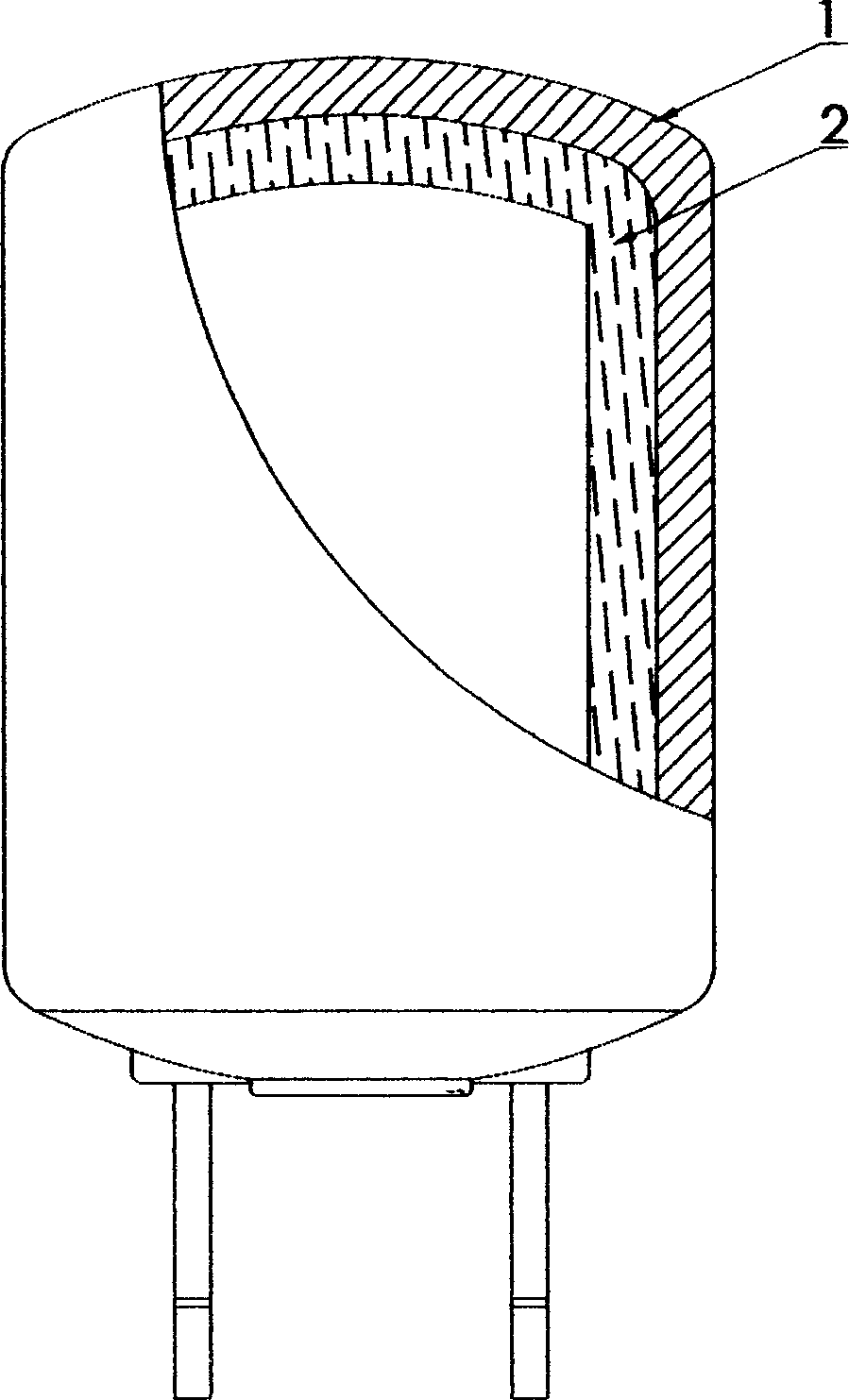

Image

Examples

Embodiment 1

[0013] The inner surface of the metal body of the inner tank of the water heater is degreased with a cleaning solution, and then sandblasted. Pour the prepared liquid of organic ash polytetrafluoroethylene mixture into the spray filter system, and when the spray gun is at an angle of 45-90°, start the spray filter system to spray the coating liquid on the inner surface of the metal body. Bake in an oven at 280°C for 10 minutes. As a result, its inner surface is covered with a homogeneous coating of the machine dusted polytetrafluoroethylene mixture. The thickness of the coating was measured to be 12 microns.

Embodiment 2

[0015] The inner surface of the metal body of the inner tank of the water heater is degreased with a cleaning solution, and then sandblasted. Pour the prepared PTFE base oil into the spray filter system, and when the spray gun is at an angle of 45-90°, start the spray filter system, spray the liquid on the inner surface of the metal body, and put it in an oven at 150°C Inside, bake for 4 minutes. Press the technique of embodiment 1 again, spray polytetrafluoroethylene top oil. As a result, its inner surface is covered with a uniform coating of polytetrafluoroethylene. The thickness of the coating was measured to be 25 microns.

Embodiment 3

[0017] The inner surface of the metal body of the inner tank of the water heater is degreased with a cleaning solution, and then sandblasted. Pour the prepared polytetrachlorethylene powder into the electrostatic powder spraying system, start the electrostatic powder spraying system, spray the powder on the inner surface of the metal body of the water heater liner, and bake it in an oven at 280°C for 10 minutes. As a result, its inner surface is covered with a uniform coating of polytetrachlorethylene. The thickness of the coating was measured to be 12 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com