Method for synthesizing titanate series electronic ceramic nano-crystalline materials

A synthesis method and technology of electronic ceramics, which is applied in the field of synthesis of titanate electronic ceramic nanocrystals, can solve the problems of high-end titanate products such as high price and unbalanced market supply, and achieve low cost, small number of crystals, and low energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

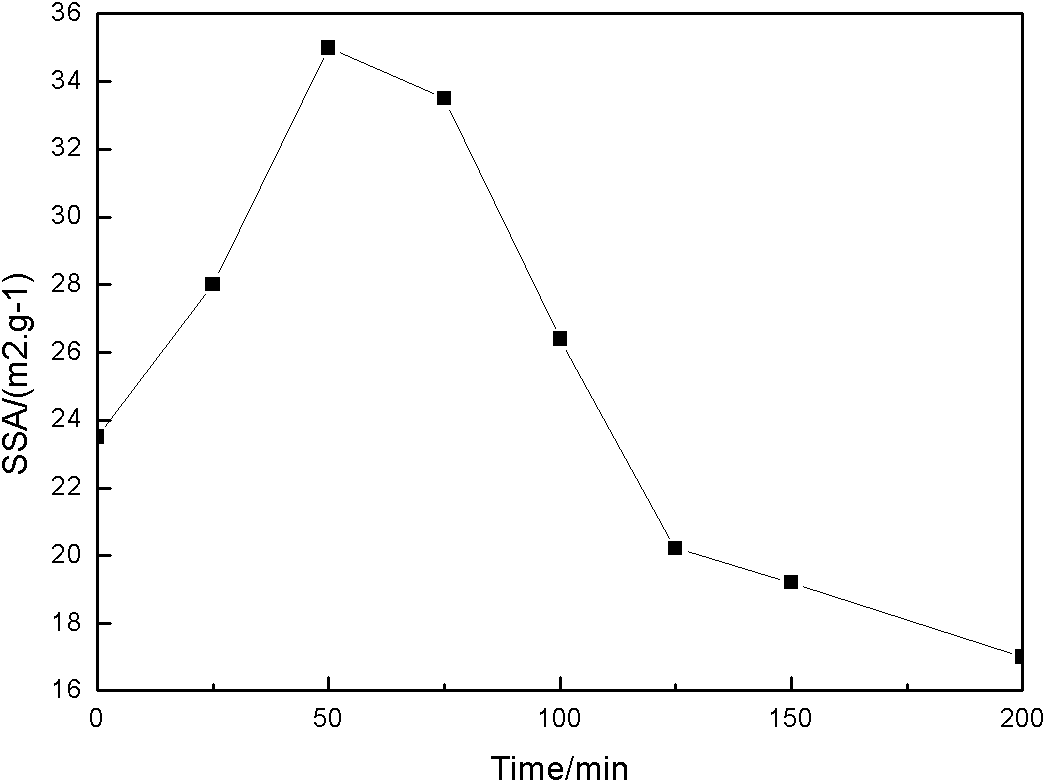

Image

Examples

Embodiment 1

[0035] 1. Ingredients ball mill: Accurately weigh 1001.695g BaCO respectively 3 and 498.305g TiO 2 .H 2 O, high-energy ball mill activation for 60 minutes, the ball-to-material ratio was 20:1, and the mill speed was 1500 r / min. Then weigh a total of 2750g NaOH and 2250g KOH, add the above-mentioned ball mill equipped with reactants to continue ball milling for 30min, the mill speed is 800r / min, and finally all are transferred into a Teflon reaction vessel with a volume of 2L.

[0036]2. Heating reaction: seal the above Teflon reaction vessel, heat in a sand bath at 180°C for a total heating time of 240min, and then cool naturally to room temperature.

[0037] 3. Washing and drying: After washing the reaction product collected in step 2 twice with 90°C deionized water, transfer it to a ball mill, add deionized water to make a 2:1 slurry, ball mill for 30 minutes again, centrifuge, vacuum Dry to obtain barium titanate ceramic powder.

[0038] Table 1 compares the performance...

Embodiment 2

[0043] 1. Ingredients ball mill: accurately weigh 590.520g SrCO 3 and 391.600g TiO 2 .H 2 O, high-energy ball mill activation for 60 minutes, the ball-to-material ratio was 20:1, and the mill speed was 1600 r / min. Then weigh a total amount of 2156g NaOH and 1764g KOH, add the above-mentioned ball mill equipped with reactants to continue ball milling for 30min, the mill speed is 800r / min, and finally all are transferred into a Teflon reaction vessel with a volume of 2L.

[0044] 2. Heating reaction: Seal the above-mentioned Teflon reaction vessel, heat it with a muffle furnace, raise it to 170°C, keep it warm for 2 hours, and then cool it down to room temperature naturally.

[0045] 3. Washing and drying: use 90°C deionized water to prepare the reaction product collected in step 2 into a slurry, dissolve and age for 30 minutes, and then centrifuge. After separation, the above washing steps were repeated twice. Vacuum drying to obtain strontium titanate ceramic powder A.

...

Embodiment 3

[0048] 1. Ingredients ball mill: accurately weigh 590.520g SrCO 3 and 319.200g commercial TiO 2 , activated by high-energy ball milling for 60 minutes, the ball-to-material ratio was 20:1, and the mill speed was 1600r / min. Then take the total amount of 2156g NaOH and 1764g KOH, add the above-mentioned ball mill equipped with reactants to continue ball milling for 30min, the mill speed is 800r / min, and finally all are transferred into a Teflon reaction vessel with a volume of 2L.

[0049] 2. Heating reaction: Seal the above-mentioned Teflon reaction vessel, heat it with a muffle furnace, raise it to 170°C, keep it warm for 2 hours, and then cool it down to room temperature naturally.

[0050] 3. Washing and drying: use 90°C deionized water to prepare the reaction product collected in step 2 into a slurry, dissolve and age for 30 minutes, and then centrifuge. After separation, the above washing steps were repeated twice. Vacuum drying to obtain strontium titanate ceramic powd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com