Novel special concrete contraction reducing type compacting agent

A compacting agent and concrete technology, applied in the field of concrete admixtures, can solve the problems affecting the volume stability of concrete, adverse effects on concrete strength, poor concrete impermeability, etc., and achieves obvious shrinkage and crack prevention effects, simple and environmentally friendly synthesis process, tight bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0043]

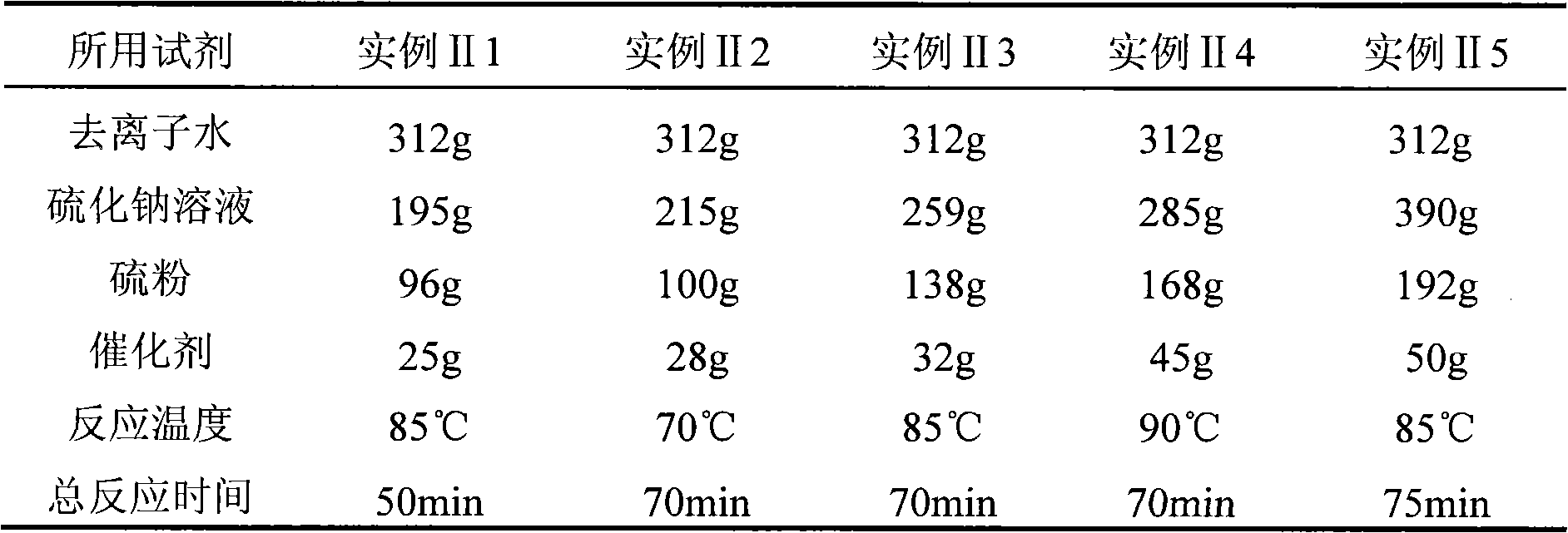

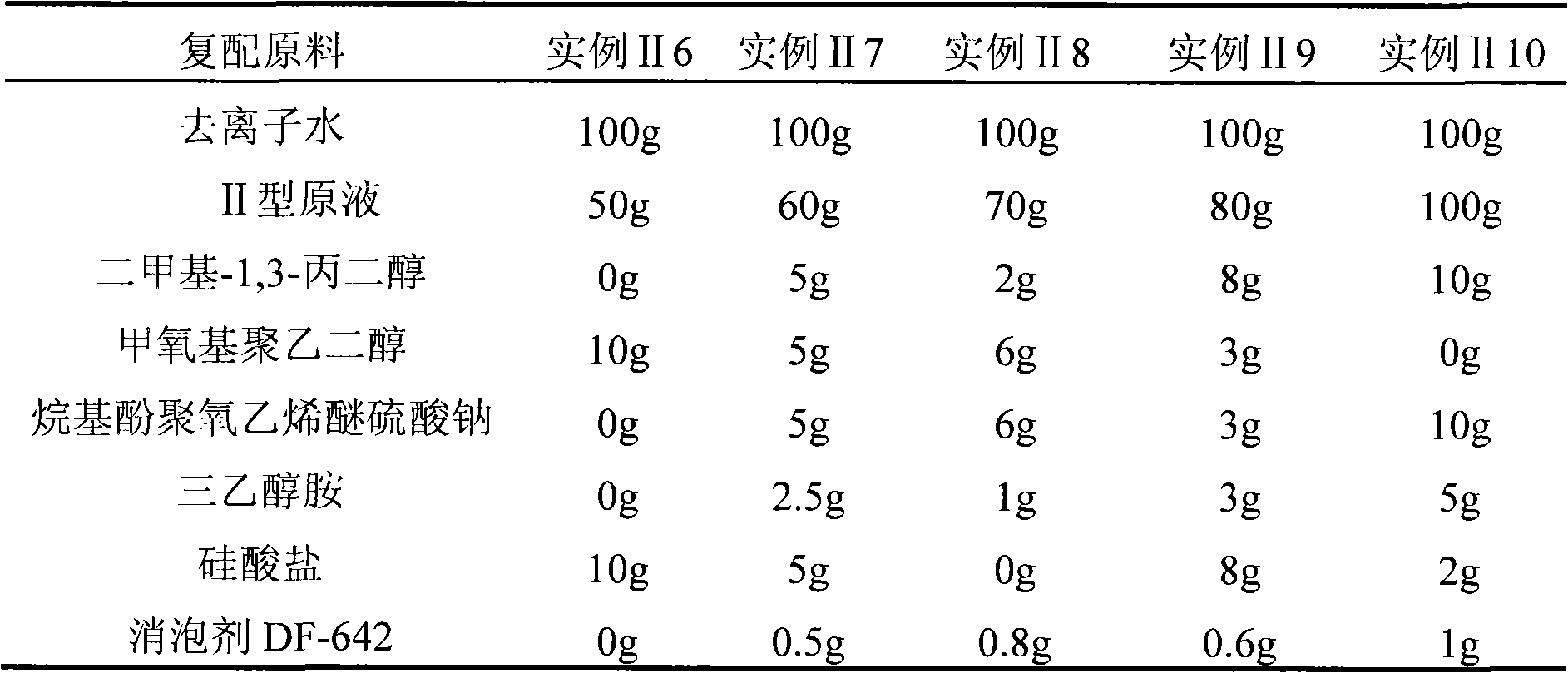

[0044] Type II compound compacting agent

[0045] Mix and stir the following formula type II stock solution and various substances evenly to obtain type II compound compacting agent, namely:

[0046] Ionized water 100g,

[0047] Type II stock solution 50g~100g,

[0048] Dimethyl-1,3-propanediol 0g~10g,

[0049] Methoxy polyethylene glycol 0g~10g,

[0050] Alkylphenol polyoxyethylene ether sodium sulfate 0g~10g,

[0051] Triethanolamine 0g~5g,

[0052] Silicate (sodium silicate, lithium silicate, potassium silicate) 0g~10g,

[0053] French Rhodia defoamer DF-642 0g~1g.

[0054] Concrete embodiment is:

[0055]

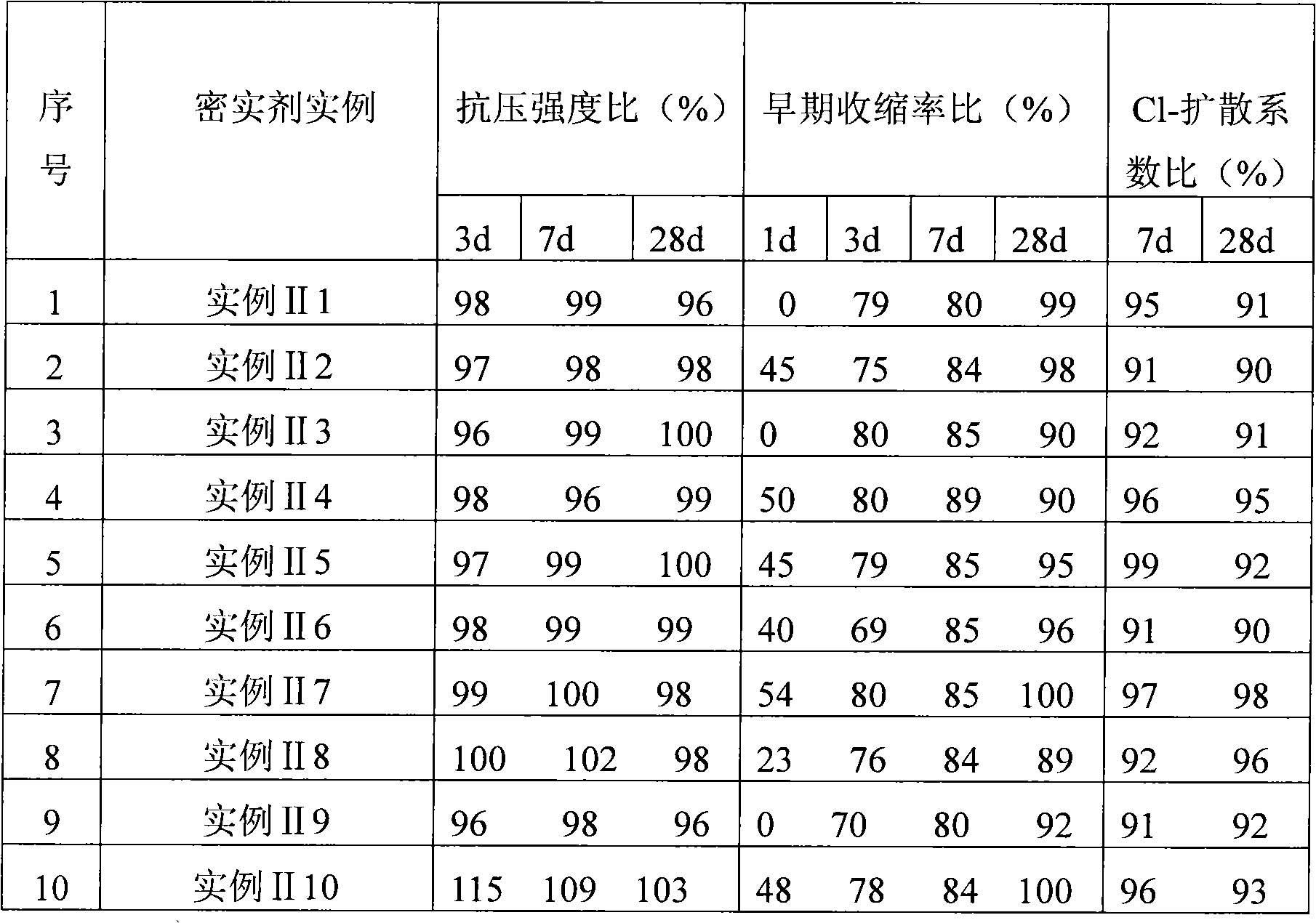

[0056] The above products have been tested in accordance with the waterproofing agent industry standard (JC474-2008) for compressive strength ratio, early shrinkage ratio, chloride ion diffusion coefficient ratio, etc. The benchmark concrete mix ratio is:

[0057] Cement: 330kg

[0058] Medium sand: 744kg

[0059] Stone (5~25mm): 1116Kg

[0060...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com