Method for preparing special aromatic polyoxadiazole and flame-retardant high-temperature resistant polyoxadiazole fiber thereof

A polyoxadiazole and aromatic technology, applied in the fields of fiber chemical characteristics, wet spinning method, single-component synthetic polymer rayon, etc., can solve problems such as complex synthesis process, hydrogen bromide poisoning, and complicated polymer structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Example 1. Using oleum as a solvent to prepare halogen-containing flame-retardant and high-temperature-resistant polyoxadiazole fibers and their special POD polymers

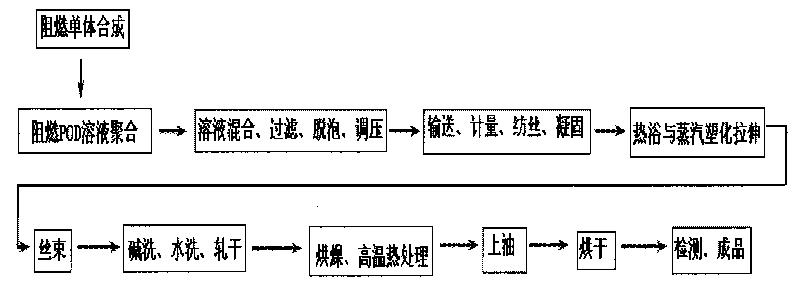

[0068] Polyoxadiazole fibers can be figure 1 The process flow diagram shown in the preparation.

[0069] 1. Preparation of POD polymer

[0070] Preparation of Flame Retardant Modified Monomer

[0071] Pass bromine into a closed reaction kettle containing isophthalic acid and oleum, and use FeCl 3 or FeBr 3 As a catalyst, it was stirred and reacted at 120°C for 5 hours, and excess gas was removed after the reaction to obtain Br-containing flame-retardant modified isophthalic acid. The equivalent ratio (molar ratio) of each reactant is: isophthalic acid: SO 3 :Br 2 : FeCl 3 (FeBr 3 )=1:20:1.2:0.05. Tested with an ultraviolet spectrophotometer, the halogen substitution rate is 85-95%.

[0072] Polymerization of POD solution

[0073] Hydrazine sulfate (NH 2 NH 2 .H 2 SO 4 ) dissolved in SO at 8...

Embodiment 2

[0084] Example 2, using fuming sulfuric acid as a solvent to prepare phosphorus-containing flame-retardant and high-temperature-resistant polyoxadiazole fibers and their special POD polymers

[0085] 1. Preparation of POD polymer

[0086] Preparation of Flame Retardant Modified Monomer

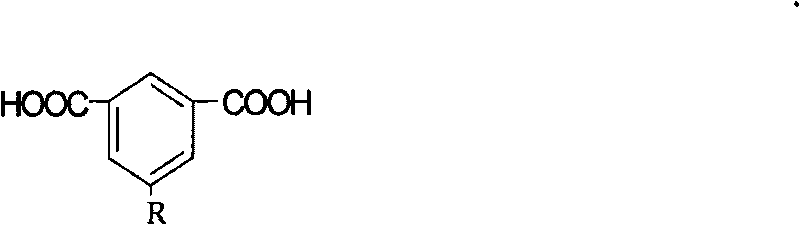

[0087] Dissolve diphenyloxy(sulfur)phosphine in dioxane (Dioxane), and then add catalyst AlCl to the solvent 3 , and m-xylene was slowly added dropwise under reflux at 85°C. After the dropwise addition, reflux reaction was carried out for 6 hours. After the reaction was completed, a pure m-xylene substitute was obtained by washing and recrystallization. The m-xylene substitute is oxidized twice with potassium permanganate to obtain a flame-retardant isophthalic acid monomer substituted by diphenyl (sulfur) phosphine, and the molar ratio of each reactant is: solvent: AlCl 3 : substituent: m-xylene=15: 1.15: 1.5: 1, the amount of potassium permanganate twice and the monomer (m-xylene substitut...

example 3

[0090] Example 3, polyphosphoric acid is used as a solvent to prepare halogen-containing flame-retardant and high-temperature-resistant polyoxadiazole fibers and their special POD polymers

[0091] 1. Preparation of POD polymer

[0092] The preparation of the flame retardant modified monomer is the same as in Example 1.

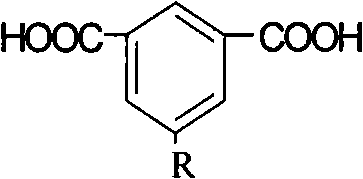

[0093] Polymerization of POD solution

[0094] Hydrazine sulfate (NH 2 NH 2 .H 2 SO 4 ) dissolved in P at 110°C 2 o 5 In polyphosphoric acid with a mass percent content of 80% and a degree of polymerization of 4, terephthalic acid and Br-containing flame-retardant modified isophthalic acid (the compound in which R is Br in formula I) are sequentially added, and various reactions The molar ratio is P 2 o 5 : terephthalic acid: flame-retardant modified isophthalic acid: hydrazine sulfate = 10: 0.90: 0.10: 1.02. The reaction temperature in the pre-polymerization stage is 110°C, and the reaction time is 4h; the reaction temperature in the polymerization...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com