Preparation method of W-Cu electrical contact

A technology for electrical contacts and electrical contact materials, which is applied to circuits, electrical switches, electrical components, etc., can solve the problems of cumbersome operation, high consumption and high cost, and achieve the effect of reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

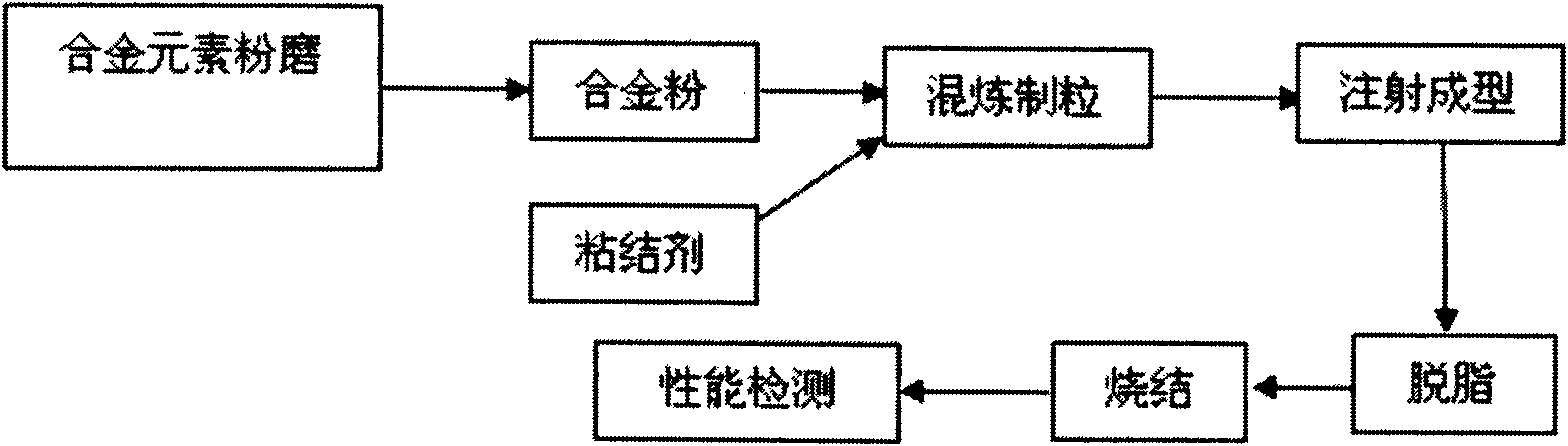

Method used

Image

Examples

Embodiment 1

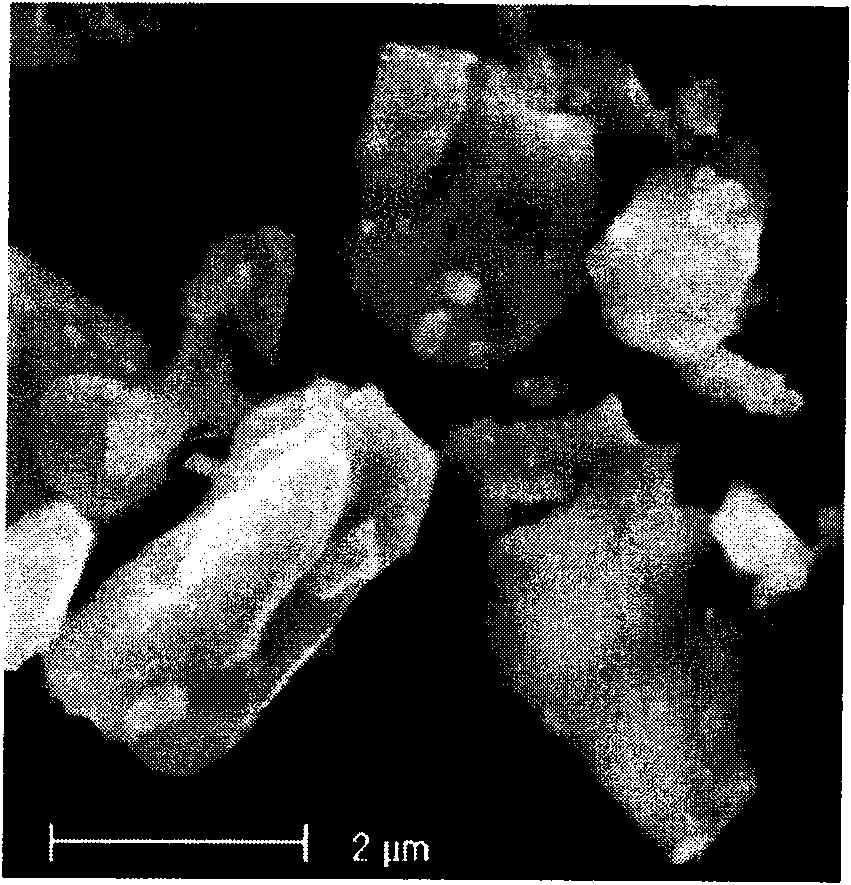

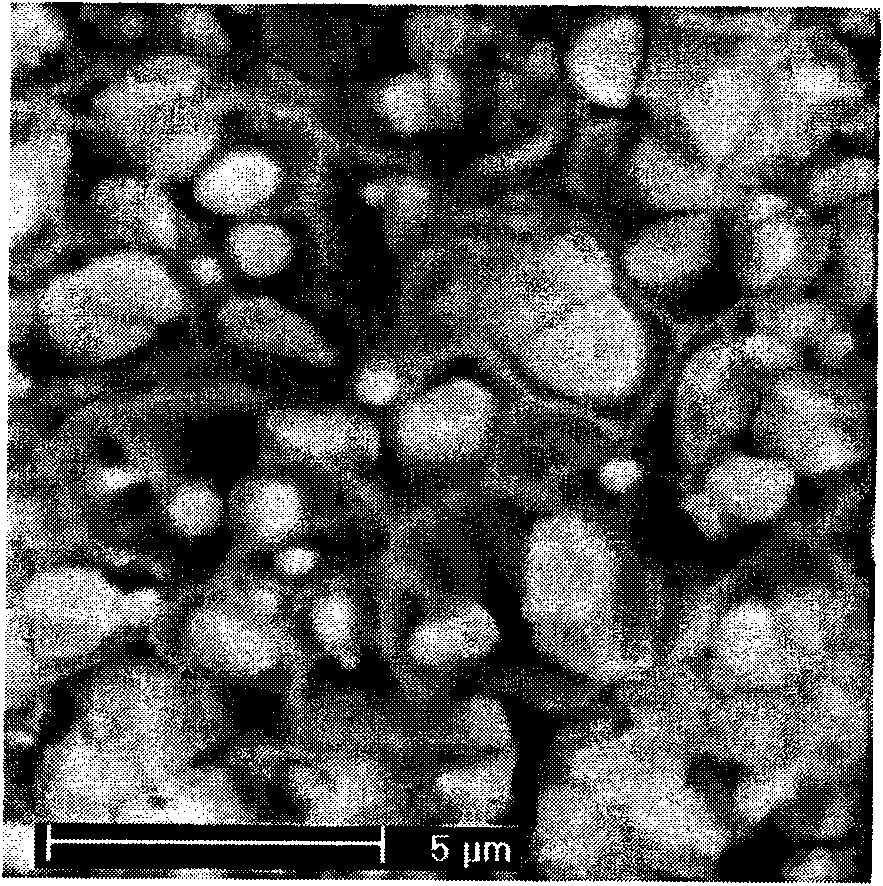

[0024] Weigh 840g of W powder, 150g of Cu powder, and 10g of Ni powder, and mill them in a ball mill for 10 hours; mix the alloy powder and binder at a volume ratio of 1.63 after ball milling, and knead at 165°C for 2 hours; then pass through an extruder Make the feed at 130°C; put the prepared feed into the injection molding machine for injection, the injection temperature is 130°C, the injection pressure is 135Mpa, and the mold temperature is 50°C; after that, the green body is completely immersed in the temperature of 30°C In the n-heptane solvent for 2 hours, the paraffin and stearic acid components were dissolved; then the green body was dried in a constant temperature drying oven at 40°C and then put into a tube furnace with a flow rate of 2.5ml / min·cm 2 Thermal degreasing under a protective hydrogen atmosphere: heating at 3°C / min to 180°C, holding for 60 minutes, then heating at 3°C / min to 250°C, holding for 120 minutes, and then heating at 3°C / min Heat to 350°C, hold...

Embodiment 2

[0026] Weigh 599 g of W powder, 400 g of Cu powder, and 1 g of Ni powder, and mill them in a ball mill for 70 hours; mix the alloy powder and binder at a volume ratio of 1.17 after ball milling, and knead at 140°C for 2 hours; then pass through an extruder Make the feed at 130°C; put the prepared feed into the injection molding machine for injection, the injection temperature is 165°C, the injection pressure is 80Mpa, and the mold temperature is 40°C; after that, the green body is completely immersed in the temperature of 45°C in a n-heptane solvent for 6 hours to dissolve the paraffin and stearic acid components; then put the green body in a constant temperature drying oven at 40°C and then put it into a tube furnace with a flow rate of 2.5ml / min·cm 2 Thermal degreasing under a nitrogen protective atmosphere: heat to 40°C at a rate of 3°C / min, hold for 60 minutes, then heat to 250°C at a rate of 3°C / min, hold for 60 minutes, and then heat at a rate of 3°C / min Heat to 350°C,...

Embodiment 3

[0028] Weigh 745g of W powder, 250g of Cu powder, and 5g of Co powder, and mill them in a ball mill for 40 hours; mix the alloy powder and binder at a volume ratio of 1.40 after ball milling, and knead at 150°C for 2 hours; then pass through an extruder Make the feed at 140°C; put the prepared feed into the injection molding machine for injection, the injection temperature is 140°C, the injection pressure is 120Mpa, and the mold temperature is 60°C; after that, the green body is completely immersed in the temperature of 60°C In the n-heptane solvent for 10 hours, the paraffin and stearic acid components were dissolved; then the green body was dried in a constant temperature drying oven at 40°C and then put into a tube furnace with a flow rate of 2.5ml / min·cm 2 Under the protective atmosphere of argon gas, thermal degreasing: heating to 180°C at a speed of 3°C / min, holding for 50 minutes, heating at a speed of 3°C / min to 250°C, holding for 100 minutes, and then heating at a sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com