Graduated porous titanium dioxide microsphere, and preparation method and applications thereof

A hierarchical porous and titanium dioxide technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, material resistance, etc., can solve the problems of complex preparation methods, achieve simple and practical process, facilitate large-scale production, and enhance the effect of gas sensing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The beneficial effects of the present invention will be described in detail below in conjunction with the embodiments of the accompanying drawings, aiming at helping readers better understand the essence of the present invention, but not limiting the implementation and protection scope of the present invention.

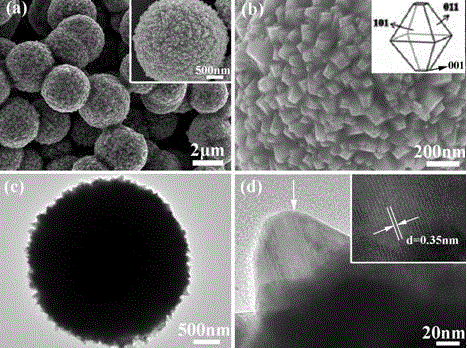

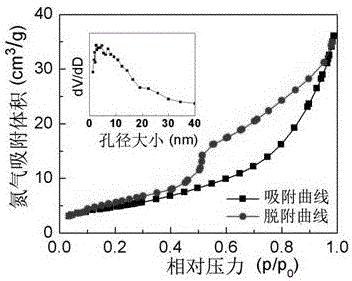

[0016] The graded porous titanium dioxide has a microspherical structure with a diameter of 2-5 μm. The graded porous titanium dioxide microspheres are assembled from truncated octahedral nanocrystals, and the diameter of the truncated octahedral nanocrystals is 50-100 nm, and The high-energy {001} crystal face of the anatase phase is exposed, and the hierarchically porous titanium dioxide microspheres have a hierarchical porous structure, and the pore diameters thereof are distributed in the range of 5-20 nm.

[0017] The preparation process of the hierarchical porous titanium dioxide microspheres is completed according to the following steps: first, titanium s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com