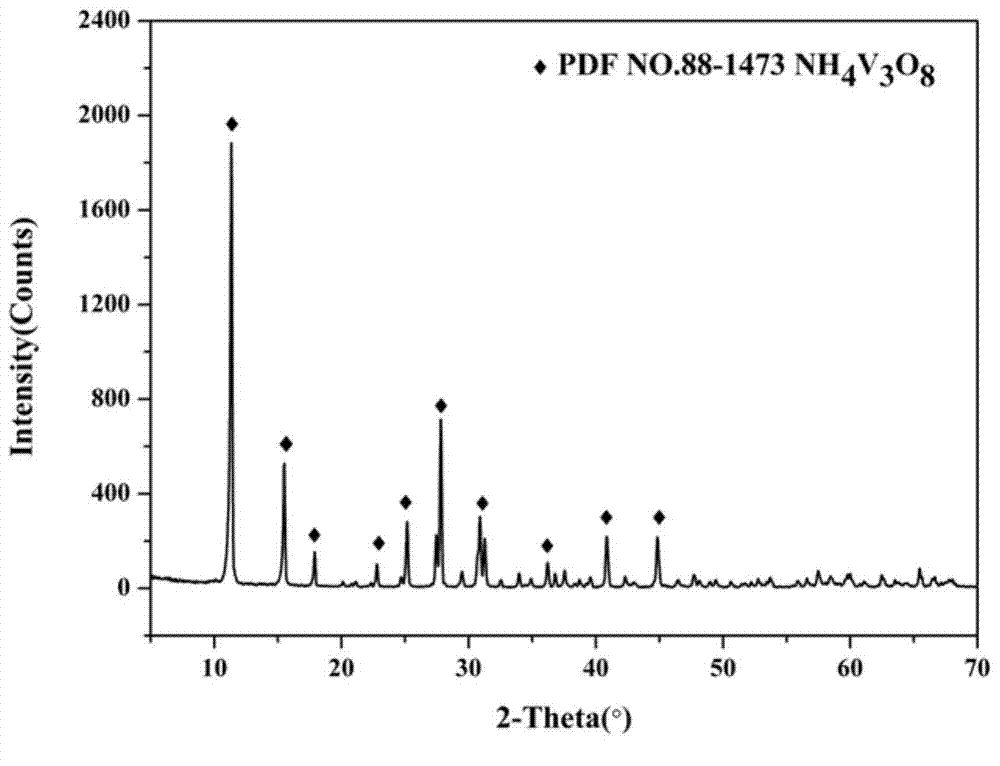

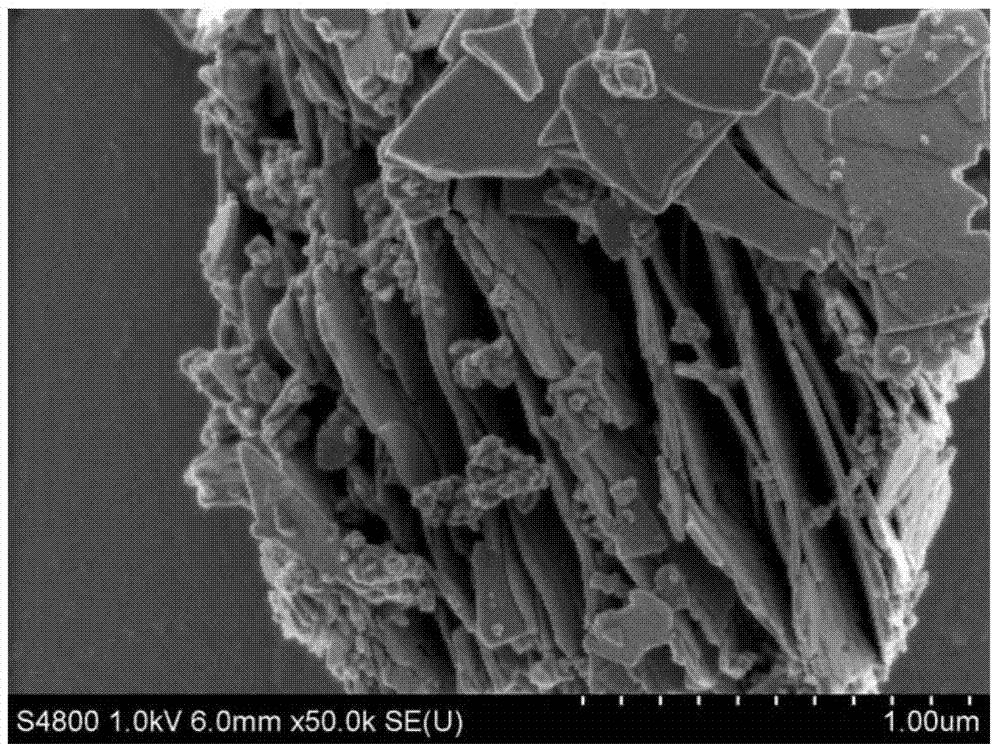

Preparation method of sandwiched-layer-shaped NH4V3O8 nanocrystalline

A nanocrystal and interlayer technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of difficult control of the reaction process, occurrence of side reactions, low purity of products, etc., to achieve good electrical Chemical performance, short reaction cycle, high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) The analytically pure ammonium metavanadate (NH 4 VO 3 ) was dissolved in deionized water at 50°C, stirred magnetically for 0.5h to dissolve ammonium metavanadate evenly, and prepared NH 4 + The concentration is 0.01mol / L of NH 4 VO 3 Solution, denoted as A solution;

[0026] 2) Use 1mol L -1 dilute hydrochloric acid solution to adjust the pH value of solution A to 6.0 to obtain B solution;

[0027] 3) Pour the B solution into the reactor, let the microwave act on the B solution, the microwave power is controlled at 400-600W, the temperature is measured by a platinum resistance, and the temperature is raised from room temperature to 90°C at a heating rate of 10°C / min, and then kept for 60min , and then naturally cooled to room temperature;

[0028]4) Open the reactor, centrifuge the suspension in the reactor to obtain a powder product, soak the powder product in deionized water for 10 minutes, wash 5 times, then soak in absolute ethanol for 10 minutes, wash 5 ...

Embodiment 2

[0031] 1) The analytically pure ammonium metavanadate (NH 4 VO 3 ) was dissolved in deionized water at 60°C, stirred magnetically for 0.5h to dissolve ammonium metavanadate evenly, and prepared NH 4 + The concentration is 0.03mol / L of NH 4 VO 3 Solution, denoted as A solution;

[0032] 2) Use 2mol L -1 The dilute hydrochloric acid solution adjusts the pH value of solution A to be 5.50, obtains B solution;

[0033] 3) Pour the B solution into the reactor, let the microwave act on the B solution, the microwave power is controlled at 400-600W, and the temperature is measured by a platinum resistance, and the temperature is raised from room temperature to 80°C at a heating rate of 10°C / min, and then kept for 90min , and then naturally cooled to room temperature;

[0034] 4) Open the reactor, centrifuge the suspension in the reactor to obtain a powder product, soak the powder product in deionized water for 10 minutes, wash 5 times, then soak in absolute ethanol for 10 minute...

Embodiment 3

[0036] 1) The analytically pure ammonium metavanadate (NH 4 VO 3 ) was dissolved in deionized water at 55°C, stirred magnetically for 0.75h to dissolve ammonium metavanadate evenly, and prepared NH 4 + The concentration of 0.05mol / L NH 4 VO 3 Solution, denoted as A solution;

[0037] 2) Use 3mol L -1 dilute hydrochloric acid solution to adjust the pH value of solution A to 5.0 to obtain B solution;

[0038] 3) Pour the B solution into the reactor, let the microwave act on the B solution, the microwave power is controlled at 400-600W, and the platinum resistance is used to measure the temperature. After the temperature is raised from room temperature to 70°C at a heating rate of 10°C / min, the temperature is kept for 120min. , and then naturally cooled to room temperature;

[0039] 4) Open the reactor, centrifuge the suspension in the reactor to obtain a powder product, soak the powder product in deionized water for 10 minutes, wash 5 times, then soak in absolute ethanol ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com